Description

Zaber's X-VSR-SV2 Series offers a cutting-edge solution for high-vacuum applications with its computer-controlled, motorized vertical lift stages. These devices are engineered to handle loads up to 10 kg, making them an ideal choice for precision motion control in demanding environments. The series is designed to operate efficiently with a standard 24 V or 48 V power supply, ensuring ease of integration into existing systems.

These versatile stages connect seamlessly to the RS-232 or USB ports of any computer, allowing for straightforward control and operation. A standout feature of the X-VSR-SV2 Series is its ability to daisy-chain with other Zaber products, sharing both power and communication lines. This capability simplifies the setup and reduces the complexity of managing multiple devices, as only four feedthrough wires are needed for control via a serial port with an X-PIB adaptor.

The X-VSR-SV2 Series exemplifies Zaber's commitment to 'plug and play' solutions, offering a user-friendly experience from setup to operation. Whether you are considering a single-unit application or a multi-axis system, these vertical lift stages provide a reliable and efficient platform. With their high-vacuum compatibility and robust design, they are particularly well-suited for environments where precision and reliability are paramount.

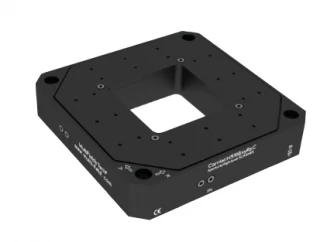

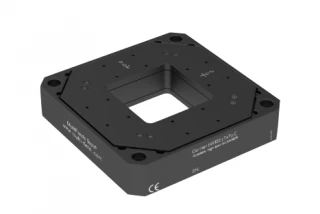

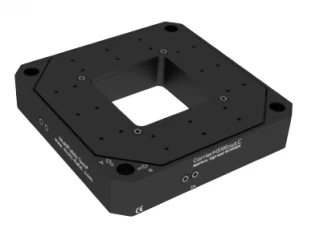

High Vacuum Motorized Vertical Stage X-VSR40A-SV2

Specifications

| Vacuum Compatible: | Yes |

|---|---|

| Microstep Size (default Resolution): | 0.09525 um |

| Built-in Controller: | Yes |

| Travel Range: | 40 mm |

| Accuracy (unidirectional): | 35 um |

| Backlash: | Other |

| Loaded Backlash (10 N): | <10 um |

| Maximum Speed: | 48 mm/s |

| Guiding Mechanism: | Crossed Roller Slides |

| Voltage Requirement: | DC 24V |

| Travel Range: | 40 mm |

| Maximum Speed: | 48 mm/s |

| Load Capacity: | 10 kg |

| Retracted Height: | 55 or 85 mm |

| Microstep Size (Default Resolution): | 0.09525 µm |

| Accuracy (unidirectional): | 35 µm |

| Repeatability: | < 1 µm |

| Horizontal Runout: | < 35 µm |

| Linear Motion Per Motor Rev: | 1.2182 mm |

| Motor Type: | Stepper (2 phase) |

| Axes Of Motion: | 1 |

| Operating Temperature Range: | 0-50 °C |

| RoHS Compliant: | Yes |

| CE Compliant: | Yes |

| Weight: | 0.770 kg |

Features

- Vacuum Compatibility: Suitable for high vacuum environments up to 10-6 Torr.

- Travel Options: Available in 20 mm or 40 mm travel distances.

- Speed and Thrust: Capable of speeds up to 48 mm/s and a peak thrust of 200 N.

- Load Capacity: Supports loads up to 10 kg.

- Compact Design: Features a retracted height of either 55 mm or 85 mm.

- Integrated Controller: Built-in controller allows for easy daisy-chaining with other Zaber products.

- Efficient Wiring: Requires only four feedthrough wires to control all units in the daisy-chain via serial port (with an X-PIB adaptor).

- Plug and Play: Designed for easy setup and operation, ideal for multi-axis systems.

- Communication Interface: Connects via RS-232 or USB port, supporting Zaber ASCII and Zaber Binary protocols.

- Precision Movement: Features a microstep size of 0.09525 µm and repeatability of < 1 µm.

- Robust Construction: Utilizes a crossed-roller bearing guide type for enhanced stability.

- Power Requirements: Operates on a 24-48 VDC power supply.

- Compliance: RoHS and CE compliant.

- Temperature Range: Operates efficiently within a temperature range of 0-50 °C.

Applications

- Vacuum Material Handling: Precise vertical actuation for material transfer in high vacuum environments.

- Optical System Alignment: Accurate Z-axis positioning for mirrors, lenses, and vacuum-compatible optical assemblies.

- Semiconductor Processing: Ideal for wafer lifting, sample positioning, and microfabrication processes.

- Scientific Research: Supports experimental setups requiring high stability and vacuum compatibility.

- Multi-Axis Vacuum Stages: Integrated into XYZ or multi-axis systems for automated vacuum manipulations.

Frequently Asked Questions

What is the load capacity of the X-VSR-SV2 Series device?

What type of power supply is required for the X-VSR-SV2 Series device?

Can the X-VSR-SV2 Series device be connected to a computer?

How many feedthrough wires are required to control all units in the daisy-chain via serial port?

What is the maximum speed of the X-VSR-SV2 Series device?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle