Description

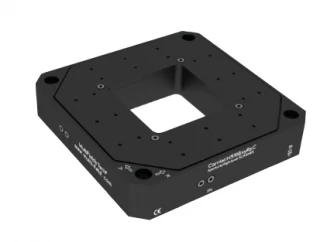

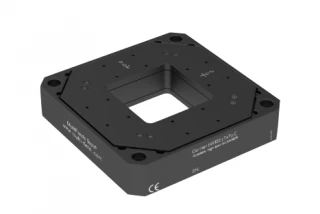

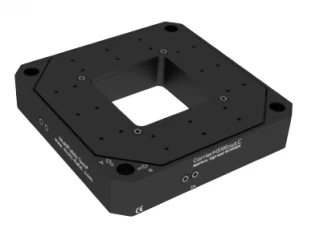

The LS65z.Lab.O/.R.NM Series Vertical Motion Stage is a compact, high-precision z-axis actuator designed for laboratory and research environments requiring ultra-fine vertical positioning. With a footprint of just 65 mm × 65 mm and a vertical height of 42.5 mm, this piezo-driven stage supports travel ranges up to 10 mm with impressive mini step sizes down to ~10 nm.

The system accommodates two sensor options: a resistive sensor (.R) for economic yet precise control (100–200 nm resolution), and an optical encoder (.O) offering sub-10 nm resolution (including options for 4.88 nm, 2.44 nm, or even 1 nm). Designed for low-noise operation, it features a quiet 20 kHz drive frequency and supports closed-loop control.

Constructed from non-magnetic and vacuum-compatible materials including ceramics, stainless steel, and aluminum, the LS65z.Lab series is also available in high vacuum (.HV) and ultra-high vacuum (.UHV) configurations. Standard shielded cable connectors and optional multi-axis stacking adapters ensure easy integration. Whether in microscopy, optics alignment, or material testing, this stage offers reliable, precise vertical motion in a compact, quiet, and customizable platform.

LS65z.Lab .O/.R .NM 65mm Series Vertical Motion Stage (totally non-magnetic version supplied)

Specifications

| Load Capacity: | 0.5 kg |

|---|---|

| Vacuum Compatible: | Yes |

| Microstep Size (default Resolution): | 0.5 um |

| Built-in Controller: | No |

| Travel Range: | 10 mm |

| Accuracy (unidirectional): | 30 um |

| Backlash: | Not Specified |

| Loaded Backlash (10 N): | Not Specified |

| Maximum Speed: | 10 mm/s |

| Weight: | 0.5 kg |

| Guiding Mechanism: | Other |

| Voltage Requirement: | Other |

| Drive Frequency: | Max. 20 kHz (very quiet) |

| Pitch: | 0.3 mard |

| Sensor Type: | Resistive Sensor (.R) / Optical Encoder (.O) |

| Connector Type: | Standard shielded cable, circular & D-Sub15 |

| Cable Material: | Kapton-shielded wire, 2 mm PEEK pins |

| Operating Temperature Range: | +15 to +41 °C |

| Mount Compatibility: | Compatible with 65 mm series & multi-axis stacking adapters |

Features

- Compact Design: Measures only 65 mm × 65 mm × 42.5 mm, ideal for tight lab environments

- Extended Travel Range: Offers precise vertical motion up to 10 mm

- Ultra-Fine Resolution: Achieves ~10 nm step size for nano-level positioning accuracy

- Quiet Operation: Driven at a high-frequency of 20 kHz, ensuring minimal acoustic noise

- Closed-Loop Control: Equipped with resistive (.R) or optical (.O) sensors for feedback precision

- Flexible Sensor Options: Choose from economical resistive sensors (100–200 nm) or high-resolution optical encoders (down to 1 nm)

- High Load Capacity: Supports payloads up to 500 g while maintaining stability

- Precision Pitch/Yaw Control: Maintains angular errors within 0.3 mrad for superior alignment

- Vacuum Compatibility: Available in non-magnetic, high vacuum, and ultra-high vacuum variants

- Seamless Integration: Compatible with multi-axis systems and MC-Newton.Pro controllers

Applications

- Super-Resolution Microscopy: Delivers accurate vertical focusing for high-resolution imaging

- Optics and Photonics Alignment: Provides stable z-axis motion for precise beam alignment

- Vacuum Chamber Positioning: Ideal for sample movement in HV/UHV environments

Nanopositioning Systems: Integrates into stacked or modular platforms for 3D control - Materials Testing and Metrology: Enables controlled vertical displacement for precision experiments

Frequently Asked Questions

What is the maximum travel range of the LS65z.Lab. O/./. UHV vertical motion stage?

What is the resolution of the LS65z.Lab. O/./. UHV motion stage?

Is the LS65z.Lab. O/./. UHV compatible with vacuum environments?

What is the maximum load capacity of the LS65z.Lab.O/.R.NM/.HV/.UHV stage?

What type of sensor does the LS65z.Lab.O/.R.NM/.HV/.UHV use for position feedback?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle