Description

The PowerMir 4.8µm High-Power Pulsed Quantum Cascade Laser by mirSense delivers exceptional performance and versatility for various industrial, scientific, and defense applications. Engineered with cutting-edge technology, this laser system offers high-power pulsed output at a precise wavelength of approximately 4.8 microns. Whether used for spectroscopic analysis, gas sensing, or industrial processing, the PowerMir laser ensures reliable and consistent performance in demanding environments.

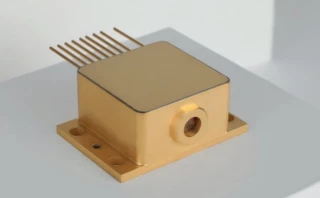

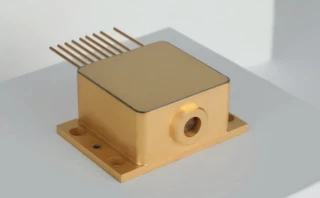

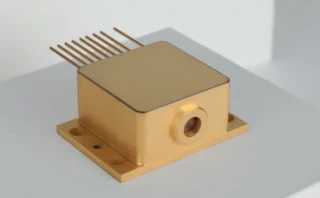

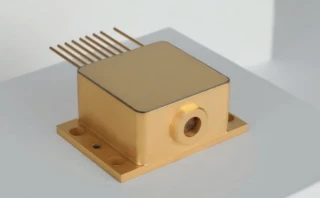

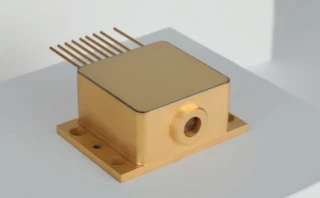

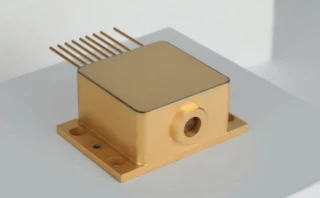

PW4800090HSNA: PowerMir 4.8um High-Power Pulsed Quantum Cascade Laser 100mW HHL Package

Specifications

| Output Power (avg): | 0.1 W |

|---|---|

| Wavelength: | 4.8 um |

| Tuning Range Around Center Wavelength: | Not Applicable |

| Packaging: | HHL-packaged laser |

| Temperature Control: | Built-in TEC and thermistor for chip temperature control |

| Beam Quality: | Enhanced by collimating lens inside the package |

| Manufacturing Process: | Burned-in during manufacturing to ensure long-term power and wavelength stability |

| Environmental Protection: | Hermetically sealed with dry N2 air inside |

| Divergence For The Lasers With Standard Beam: | 3-6 mrad |

| Pulse Frequency: | > 500 kHz |

| Mode Of Operation: | Quasi-CW, high duty cycled pulsed |

| Polarization: | Linear vertically polarized (>98%) |

| Reliability: | > 3500 hours |

| Operational Temperature Range: | -20 to +30 °C |

Features

- High-power pulsed output at 4.8 microns wavelength

- HHL-packaged laser with built-in TEC and thermistor for precise chip temperature

- control

- Collimating lens inside the package for enhanced beam quality

- Burned-in during manufacturing to guarantee long-term power and wavelength

- stability

- Hermetically sealed with dry N2 air inside for enhanced reliability

Applications

- Spectroscopic analysis

- Gas sensing and monitoring

- Industrial material processing

- Medical diagnostics

- Defense and security applications

Frequently Asked Questions

What is the wavelength of the PowerMir laser?

The PowerMir laser emits pulsed output at a precise wavelength of approximately 4.8 microns, making it ideal for various applications such as spectroscopic analysis and gas sensing.

What is the advantage of the HHL-packaged laser?

The HHL-packaged laser features a built-in Thermoelectric Cooler (TEC) and thermistor for precise chip temperature control, ensuring stable performance over extended periods.

How does the collimating lens inside the package enhance beam quality?

The collimating lens inside the package helps to shape and focus the laser beam, resulting in improved beam quality and consistency for enhanced performance in applications requiring precise laser output.

What is meant by "burned-in during manufacturing" in terms of stability?

"Burned-in during manufacturing" refers to a rigorous process where the laser undergoes extensive testing and conditioning to ensure long-term power and wavelength stability, guaranteeing reliable performance over time.

How does the hermetically sealed packaging enhance reliability?

The hermetically sealed packaging ensures that the laser is protected from external contaminants and environmental factors, maintaining its performance and reliability even in harsh operating conditions.

What are some typical applications of the PowerMir laser?

The PowerMir laser is suitable for a wide range of applications, including spectroscopic analysis, gas sensing and monitoring, industrial material processing, medical diagnostics, and defense and security applications.

Can the PowerMir laser be customized for specific applications?

Yes, mirSense offers customization options to tailor the PowerMir laser to specific application requirements, ensuring optimal performance and compatibility with diverse use cases.

What level of power output can be achieved with the PowerMir laser?

The PowerMir laser delivers high-power pulsed output, making it suitable for applications that require precise and intense laser energy delivery.

Is the PowerMir laser compatible with modulation and external control systems?

Yes, the PowerMir laser can be modulated and controlled externally using TTL signals or through Windows software, providing flexibility and ease of integration into existing systems.

What kind of warranty and support is available for the PowerMir laser?

mirSense provides comprehensive warranty coverage and technical support for the PowerMir laser, ensuring customer satisfaction and peace of mind with their investment in our laser technology.

Similar Products

Rof Optoelectronics Nanosecond Pulsed Laser Modulator Light Source Module

Beijing Rofea Optoelectronics Co,. Ltd.

PW940090HSNA: PowerMir 9.4um High-Power Pulsed Quantum Cascade Laser HHL Package 100mW

RPMC Lasers, Inc.

PW4600090HCNA: PowerMir 4.6um High Power Pulsed Quantum Turnkey System 100mW

RPMC Lasers, Inc.

PW4600090HSNA: PowerMir 4.6um High Power Pulsed Quantum Cascade Laser 100mW HHL Package

RPMC Lasers, Inc.

PW4001500HSTK1A: PowerMir 4.0um High Power Pulsed Quantum Cascade Turnkey System 1500mW Standard Beam

RPMC Lasers, Inc.

PW4001500HSNA: PowerMir 4.0um High Power Pulsed Quantum Cascade Laser 1500mW HHL Package Standard Beam

RPMC Lasers, Inc.

PW4001000HCTK1A: PowerMir 4.0um High Power Pulsed Quantum Cascade Turnkey System 1000mW Circular Beam

RPMC Lasers, Inc.

PW4001500HSNA: PowerMir 4.0um High Power Pulsed Quantum Cascade Laser 1500mW HHL Package Standard Beam

RPMC Lasers, Inc.

PW4000450HSTK1A: PowerMir 4.0um High Power Pulsed Quantum Turnkey System 450mW Standard Beam

RPMC Lasers, Inc.

PW4000450HSNA: PowerMir 4.0um High Power Pulsed Quantum Cascade Laser 450mW HHL Package Standard Beam

RPMC Lasers, Inc.

PW4000450HCTK1A: PowerMir 4.0um High Power Pulsed Quantum Turnkey System 450mW Circular Beam

RPMC Lasers, Inc.

PW4000450HCNA: PowerMir 4.0um High Power Pulsed Quantum Cascade Laser 450mW HHL Package Circular Beam

RPMC Lasers, Inc.

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle