Description

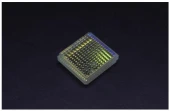

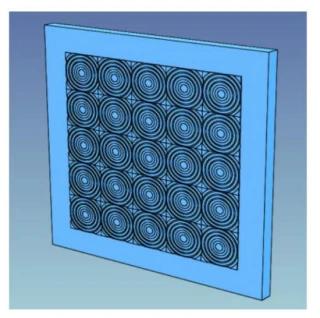

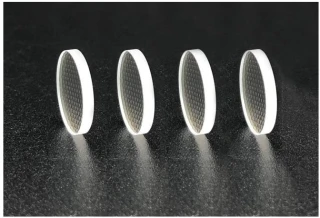

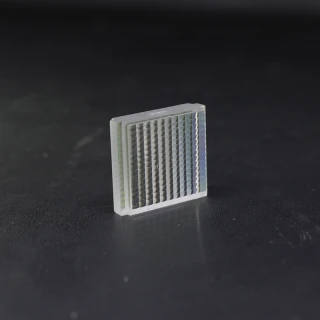

Coligh’s fused silica square microlens arrays, fabricated using photolithography technology, are made from UV fused silica and feature refractive microlenses with square apertures arranged in a square grid. These Microlens Arrays are widely used in laser beam shaping, light homogenization, imaging, optical communication, and LiDAR applications.

Fused Silica Square Microlens Arrays

Coligh Optics Technology Co.,ltd

Specifications

| Material: | Fused Silica |

|---|---|

| Grid Shape: | Square |

| Effective Focal Length (EFL): | 0.02 mm |

| Lens Pitch: | 0.01 mm |

| Array Width: | 10 mm |

| Array Height: | 10 mm |

| Array Thickness: | 1 mm |

| Product No.: | MRLQ(DD)-010 |

| Pitch: | 10.0μm |

| EFFL: | 0.02 |

| Dim: | 10×10 |

| Thick: | 1 |

| ROC: | -0.0092 |

| N.A.: | 0.354 |

| Wavelength: | 0.6328μm |

Features

Its Key Features Below:

- We use advanced photolithography and etching equipment for production. This refractive microlens array features square apertures arranged in a square grid, providing uniform beam shaping and homogenization to ensure stable laser system output.

- UV fused silica itself has excellent transmission, high-temperature resistance, and laser damage resistance. Besides UV fused silica, we also offer silicon substrates for microlens array fabrication.

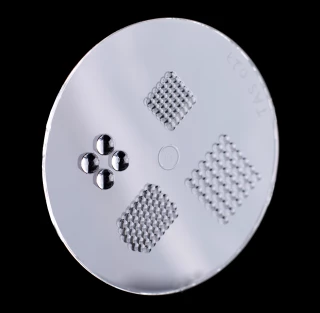

- We currently have a large inventory. The smallest unit aperture can reach 10 µm, and the largest unit aperture can reach 1500 µm. Besides standard sizes, the minimum overall diameter can be as small as 1.5 mm, and the maximum diameter can be up to 4 inches.

- The conventional energy efficiency is generally above 70%, and can be customized to 80–90%.

- The designed center wavelength depends on the customer’s system. Standard center wavelengths include 632.8 nm, 808 nm, 1545 nm, 1030 nm, 520 nm, 550 nm, 650 nm, 1064 nm, 1550 nm, 633 nm, 455 nm, 976 nm, 975 nm, meeting common laser system requirements. Coatings can be customized within the 200 nm to 20 μm range. It is suitable for quick prototype building.

Applications

- Microlens Arrays for Medical Aesthetics

In the medical aesthetics field, microlens arrays are mainly used in laser beauty treatments, skin therapy, laser hair removal systems, and photorejuvenation. Fused silica microlens arrays can be applied in picosecond, nanosecond, and long-pulse medical devices. The microlens arrays can evenly distribute laser energy and improve laser coupling efficiency. - Fused Silica Microlens for Laser LIDAR

In applications such as drones and autonomous vehicles, fused silica microlens arrays can split the emitted laser beam into multiple smaller beams, distributing and collimating the beams uniformly. Additionally, in multi-channel optical designs, microlens arrays can achieve beam focusing and separation. - Microlens Arrays for Infrared Imaging

In infrared imaging, microlens arrays can focus more infrared radiation onto the detector units. Moreover, microlens arrays can improve the spatial sampling of detector pixels. Efficient light collection and focusing help microlens arrays assist in forming clearer images.

Frequently Asked Questions

What are microlens arrays used for?

Microlens arrays are used in imaging and beam shaping, CCD detection, optical communication, multi-beam scanning, CD or DVD read/write heads, and medical and beauty devices.

What are the advantages of refractive microlens arrays?

Refractive microlens arrays offer smaller size, lighter weight, and higher integration compared to traditional optical components.

What materials are used for the microlens arrays?

The microlens arrays are made from fused silica.

What is the typical wavelength range for these microlens arrays?

The microlens arrays typically operate at a wavelength of 0.6328 μm, with some variations up to 1.545 μm.

What is the pitch size range for the microlens arrays?

The pitch size for the microlens arrays ranges from 10.0 μm to 100.0 μm.

What is the function of the Effective Focal Length (EFFL) in microlens arrays?

The Effective Focal Length (EFFL) determines how the microlens focuses light, affecting how it shapes and directs beams in optical applications.

Similar Products

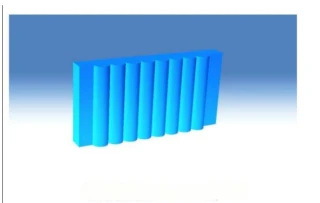

Cylindrical Microlens Array

Coligh Optics Technology Co.,ltd

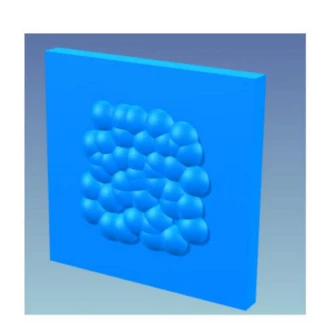

Random Aperture and Pattern Refractive Microlens Array

Coligh Optics Technology Co.,ltd

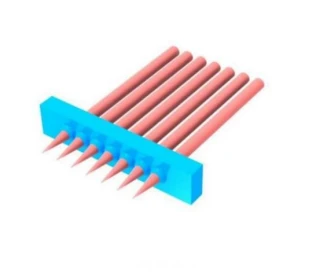

1D Circular Linear Microlens Array

Coligh Optics Technology Co.,ltd

Square Diffractive Microlens Arrays

Coligh Optics Technology Co.,ltd

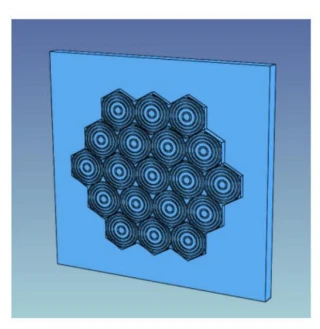

Hexagonal Diffractive Microlens Arrays

Coligh Optics Technology Co.,ltd

Silicon Square Microlens Array

Coligh Optics Technology Co.,ltd

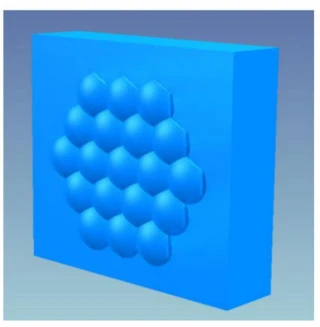

Silicon Hexagonal Microlens Arrays

Coligh Optics Technology Co.,ltd

Fused Silica Hexagonal Microlens Arrays

Coligh Optics Technology Co.,ltd

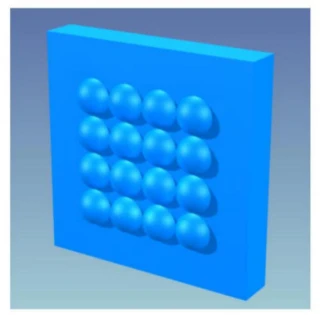

Circular Microlens Array with Square Grid

Coligh Optics Technology Co.,ltd

PicoLens High-Precision Microlens Array for Laser Medical Devices

CRYSTECH Inc.

Lithography Microlens Arrays

Coligh Optics Technology Co.,ltd

Spherical Polymer Microlens Array

ORAFOL Fresnel Optics

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle