Description

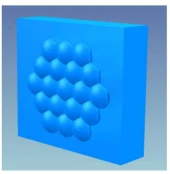

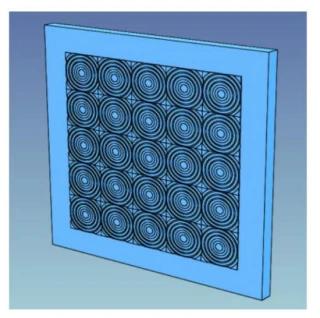

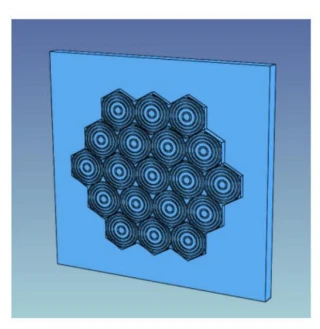

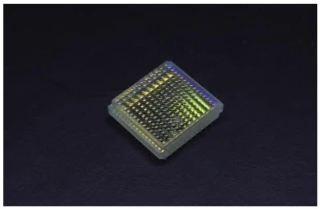

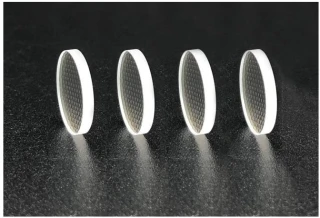

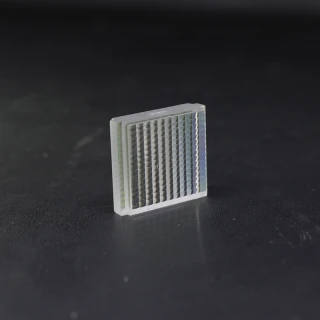

Coligh uses advanced photolithography technology to produce Fused Silica Hexagonal Microlens Arrays, which are microstructure arrays with high uniformity. This microlens array is made from high-purity fused silica, and the hexagonal structure increases the optical fill factor.

- Photolithography technology fabticating

- Fused silica as substrate

- Hexagonal microlens units

- Pitch range from 10μm to 1500μm

- Maximum size up to 4-6 inch

Fused Silica Hexagonal Microlens Arrays

Coligh Optics Technology Co.,ltd

Specifications

| Material: | Fused Silica |

|---|---|

| Grid Shape: | Hexagonal |

| Effective Focal Length (EFL): | 3 mm |

| Lens Pitch: | 0.015 mm |

| Array Width: | 25 mm |

| Array Height: | 25 mm |

| Array Thickness: | 1 mm |

| Dimension: | Dia25*1.0mm |

| ROC: | -138,00 |

| N.A.: | 25.00 |

| Design Wavelength: | 0.52μm |

Features

Fused Silica Hexagonal Microlens Arrays Key Features

- We use advanced photolithography technology combined with precision etching to achieve micro-nano structure fabrication.

- Fused silica is used as the substrate, offering high temperature resistance, corrosion resistance, and excellent transmission from UV to near-infrared with minimal absorption and scattering.

- We adopt hexagonal microlens units, which provide higher optical energy utilization and more uniform light spot distribution compared to traditional circular lens units due to their high fill factor.

- We offer standard products with a pitch range from 10μm to 1500μm.

We can support size cutting within 4 inches.

Applications

Fused Silica Hexagonal Microlens Arrays Applications

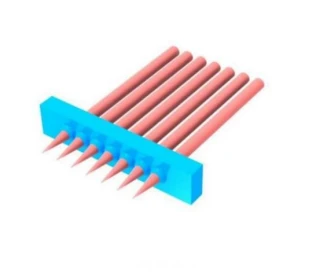

- Laser Beam Shaping and Collimation In high-power lasers, uneven energy distribution in the laser spot affects processing quality. Fused silica hexagonal microlens arrays can refract, focus, homogenize, and collimate laser beams, achieving more uniform energy distribution and stable processing.

- Optical Communication In optical communication systems, fused silica microlens arrays serve as interfaces to improve fiber coupling efficiency and reduce insertion loss. They are used in high-speed optical modules, WDM modules, and photonic integrated devices between chips and fibers.

- 3D Sensing and Imaging In devices such as 3D facial recognition and AR/VR, microlens arrays enable beam shaping, speckle generation, and optical path homogenization, enhancing image clarity and accuracy, thereby improving 3D perception capabilities.

Frequently Asked Questions

What are microlens arrays used for?

Microlens arrays are used for imaging and beam shaping, CCD detection, optical communication, multi-beam scanning, CD or DVD read/write heads, and medical and beauty devices.

What is the advantage of refractive microlens arrays over traditional optical processing?

Refractive microlens arrays offer smaller size, lighter weight, and higher integration while still being based on traditional geometric optics.

What materials are used for the refractive microlens arrays?

The refractive microlens arrays are made from fused silica.

What is the range of pitches available for the microlens arrays?

The microlens arrays have pitches ranging from 10.0μm to 100.0μm.

What does the abbreviation EFFL stand for in the product specifications?

EFFL stands for Effective Focal Length.

What is the wavelength range that these microlens arrays are designed to work with?

The microlens arrays are designed to work with wavelengths around 0.6328μm to 1.545μm.

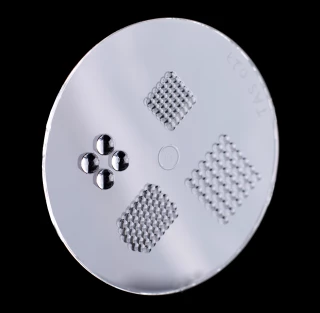

Similar Products

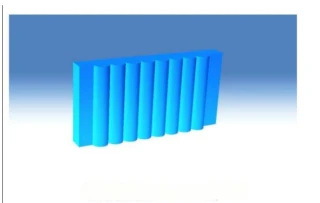

Cylindrical Microlens Array

Coligh Optics Technology Co.,ltd

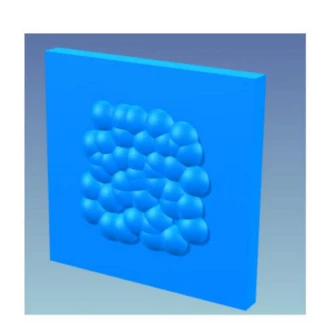

Random Aperture and Pattern Refractive Microlens Array

Coligh Optics Technology Co.,ltd

1D Circular Linear Microlens Array

Coligh Optics Technology Co.,ltd

Square Diffractive Microlens Arrays

Coligh Optics Technology Co.,ltd

Hexagonal Diffractive Microlens Arrays

Coligh Optics Technology Co.,ltd

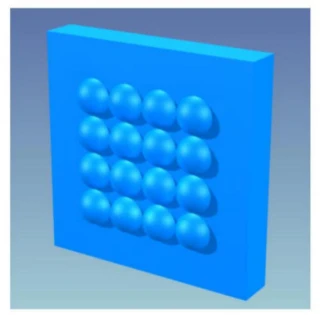

Silicon Square Microlens Array

Coligh Optics Technology Co.,ltd

Silicon Hexagonal Microlens Arrays

Coligh Optics Technology Co.,ltd

Fused Silica Square Microlens Arrays

Coligh Optics Technology Co.,ltd

Circular Microlens Array with Square Grid

Coligh Optics Technology Co.,ltd

PicoLens High-Precision Microlens Array for Laser Medical Devices

CRYSTECH Inc.

Lithography Microlens Arrays

Coligh Optics Technology Co.,ltd

Spherical Polymer Microlens Array

ORAFOL Fresnel Optics

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle