Description

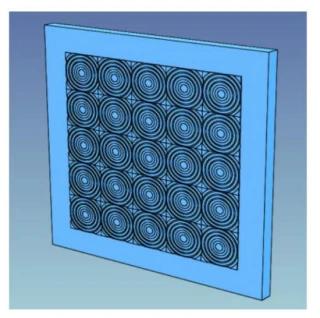

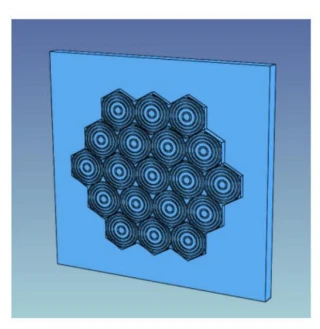

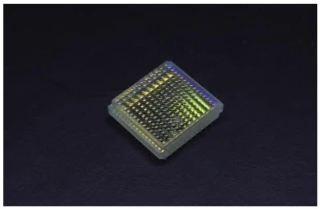

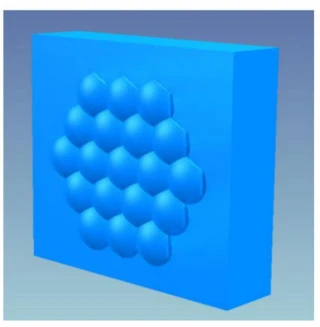

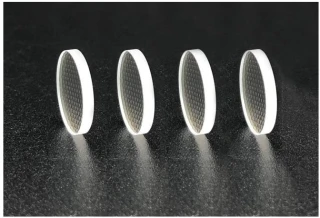

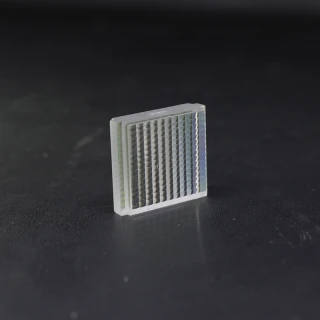

Coligh Optics uses advanced photolithography and etching techniques to manufacture Microlens Arrays. Our Circular Microlens Array with Square Grid is a high precision refractive microlens array. This type of microlens array is generally used in laser beam shaping, collimation, homogenization and 3D imaging sensing applications.

Circular Microlens Array with Square Grid

Coligh Optics Technology Co.,ltd

Specifications

| Material: | UV Fused Silica, Fused Silica |

|---|---|

| Grid Shape: | Circular |

| Effective Focal Length (EFL): | 0.185 mm |

| Lens Pitch: | 0.0265 mm |

| Array Width: | 15 mm |

| Array Height: | 14.4 mm |

| Array Thickness: | 1 mm |

Features

- The lens shape is a circular lens array, and it adopts a square arrangement, supporting spherical or aspherical design

- We use advanced photolithography technology to control the key optical parameters of the lens, such as size, array, focal length, etc., which is higher than the ordinary molding precision.

- We have two materials to choose from, fused quartz and single crystal silicon, which can meet the needs of ultraviolet, visible light or infrared bands

The standard sub-unit aperture is optional from 26.5um to 500um, and we can customize the array pitch of 10um-1500nm. - The standard center wavelengths are 532nm, 632.8nm, 1550nm, 1064nm, 850nm, 940nm. It can meet most laser wavelength requirements

Applications

- Laser Shaping

The light spot output by a high-power laser usually has uneven energy distribution and irregular shape. By placing the microlens array in front of the laser output end, the uniform shaping, collimation and divergence angle of the beam can be controlled - Laser Medical Aesthetics

In medical aesthetics, medical aesthetics laser systems such as hair removal, skin rejuvenation, picosecond and dot matrix beauty have high uniformity of laser light spot and laser energy. Microarray lenses can achieve uniform laser irradiation and optimize the energy distribution - Lidar

In laser radar equipment such as autonomous driving, robots, mapping, and security, the resolution and accuracy of laser radar are very high. By applying microarray lenses, laser beam splitting, homogenization and light spot shaping can be achieved. - Optical Communication

The optical communication module has high requirements for beam shaping and energy uniformity. The microarray lens can be used as a homogenizer of the light source to improve the signal strength of optical communication

Frequently Asked Questions

What are microlens arrays used for?

Microlens arrays are used in imaging and beam shaping, CCD detection, optical communication, multi-beam scanning, CD or DVD read/write heads, and medical and beauty devices.

What advantages do refractive microlens arrays offer?

Refractive microlens arrays offer smaller size, lighter weight, and higher integration while addressing challenges in processing high-order aspherical and freeform surfaces, small curvature radii, and small apertures.

What materials are used for the microlens arrays?

The microlens arrays are made from fused silica.

What is the typical wavelength range for these microlens arrays?

The typical wavelength range for these microlens arrays is around 0.6328μm and 0.808μm, with some products specified for 1.545μm.

What is the pitch range for the microlens arrays?

The pitch range for the microlens arrays varies from 10.0μm to 100.0μm.

What is the purpose of the numerical aperture (N.A.) in microlens arrays?

The numerical aperture (N.A.) indicates the range of angles over which the system can accept or emit light, influencing the resolution and brightness of the optical system.

Similar Products

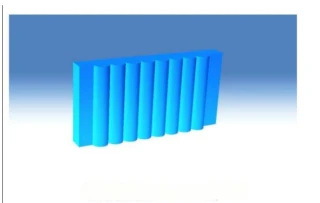

Cylindrical Microlens Array

Coligh Optics Technology Co.,ltd

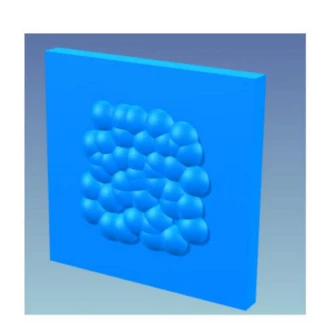

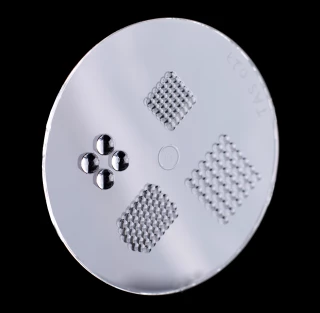

Random Aperture and Pattern Refractive Microlens Array

Coligh Optics Technology Co.,ltd

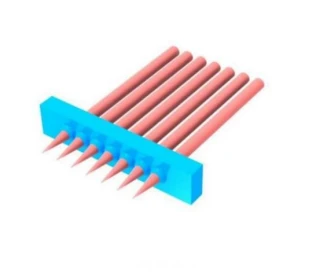

1D Circular Linear Microlens Array

Coligh Optics Technology Co.,ltd

Square Diffractive Microlens Arrays

Coligh Optics Technology Co.,ltd

Hexagonal Diffractive Microlens Arrays

Coligh Optics Technology Co.,ltd

Silicon Square Microlens Array

Coligh Optics Technology Co.,ltd

Silicon Hexagonal Microlens Arrays

Coligh Optics Technology Co.,ltd

Fused Silica Square Microlens Arrays

Coligh Optics Technology Co.,ltd

Fused Silica Hexagonal Microlens Arrays

Coligh Optics Technology Co.,ltd

PicoLens High-Precision Microlens Array for Laser Medical Devices

CRYSTECH Inc.

Lithography Microlens Arrays

Coligh Optics Technology Co.,ltd

Spherical Polymer Microlens Array

ORAFOL Fresnel Optics

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle