Description

Zaber's X-VSR Series Vertical Lift Stages are revolutionizing motion control with their advanced design and functionality. These computer-controlled, stepper actuator-driven platforms are engineered to handle loads of up to 10 kg, making them ideal for a variety of precision applications. The X-VSR Series stands out with its compact design, offering travel ranges of 20 mm or 40 mm, and remarkable speed capabilities of up to 48 mm/s. Despite their small stature, these stages deliver impressive thrust, accommodating up to 200 N, which ensures reliable performance in demanding environments.

One of the standout features of the X-VSR Series is its user-friendly operation. Each unit comes with a built-in controller, allowing for seamless integration and operation. These stages are designed to be plug-and-play, requiring only a standard 48 V power supply to function. For added convenience, an optional indexed knob is available, providing manual control for situations where computer operation is not feasible. The X-VSR Series is also equipped with locking, 4-pin, M8 connectors, ensuring secure and stable connections between units.

Designed with flexibility in mind, the X-VSR Series can be easily daisy-chained with other Zaber products, sharing power and simplifying the setup process. This feature makes it possible for multiple X-Series products to operate using a single power supply, enhancing efficiency and reducing clutter. The compact design of the X-VSR stages, with closed heights of just 55 mm or 85 mm, allows them to be mounted directly onto Zaber's LST and LSQ series linear stages, further expanding their versatility.

In summary, Zaber's X-VSR Series Vertical Lift Stages offer a perfect blend of precision, power, and convenience. Their compact design, combined with robust performance capabilities, makes them an ideal choice for those seeking reliable and efficient motion control solutions. Whether used as a standalone unit or integrated with other devices, the X-VSR Series delivers exceptional results, simplifying the complexities of motion control.

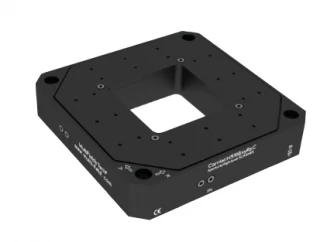

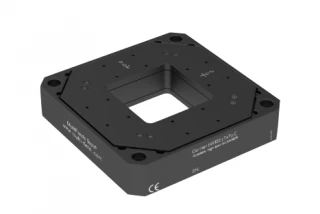

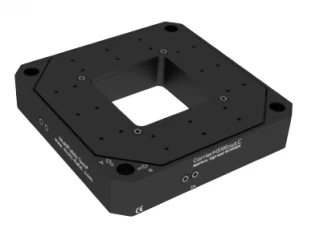

Motorized Vertical Lift Stage X-VSR20A

Specifications

| Vacuum Compatible: | Yes |

|---|---|

| Microstep Size (default Resolution): | 0.09525 um |

| Built-in Controller: | Yes |

| Travel Range: | 20 mm |

| Accuracy (unidirectional): | 35 um |

| Backlash: | ≤ 35 um |

| Loaded Backlash (10 N): | <10 um |

| Maximum Speed: | 48 mm/s |

| Guiding Mechanism: | Other |

| Voltage Requirement: | DC 24V, DC 48V |

| Maximum Current Draw: | 950 mA |

| Power Supply: | 24-48 VDC |

| Motor Rated Current: | 1500 mA/phase |

| Weight: | 0.573 kg |

Features

- Travel Options: Choose between 20 mm or 40 mm travel for versatile applications.

- Speed and Thrust: Achieve up to 48 mm/s speed and 200 N thrust for efficient motion control.

- Load Capacity: Supports loads up to 10 kg, ideal for various industrial needs.

- Compact Design: Features a retracted height of 55 mm or 85 mm, saving space without compromising performance.

- Built-in Controller: Integrated controller allows for seamless operation and easy daisy-chaining with other Zaber products.

- Connectivity: Connects via RS-232 or USB ports, with secure 4-pin M8 connectors for reliable communication.

- Manual Control: Optional indexed knob for convenient manual adjustments without a computer.

- Precision and Accuracy: Microstep size of 0.09525 µm, unidirectional accuracy of 35 µm, and repeatability of < 1 µm ensure precise movements.

- Robust Construction: Ball bearing guide type and precision lead screw for smooth and reliable operation.

- Power Requirements: Operates with a 24-48 VDC power supply and has a maximum current draw of 950 mA.

- Compliance and Safety: RoHS and CE compliant, ensuring safety and environmental standards are met.

- Easy Integration: Compatible with Zaber's LST and LSQ series linear stages for expanded functionality.

Applications

- Automated Microscopy: Enables precise z-axis focusing and objective positioning in imaging systems.

- Metrology and Inspection Systems: Provides accurate vertical motion for gauging, profiling, and surface analysis.

- Laboratory Automation: Ideal for vertical sample lifting, positioning, or device alignment in research labs.

- Optical Component Adjustment: Facilitates fine-tuned vertical alignment of optics, lasers, and sensors.

- Production and Assembly Automation: Enhances repeatable vertical motion in compact industrial setups.

Frequently Asked Questions

What is the load capacity of the X-VSR Series vertical lift stages?

What is the travel range of the X-VSR Series vertical lift stages?

What is the maximum speed of the X-VSR Series vertical lift stages?

How are the X-VSR Series vertical lift stages controlled?

What is the height of the X-VSR Series vertical lift stages?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle