Description

The LTBiS from Fibotec Fiberoptics GmbH is an advanced multi-channel laser diode drive system designed to meet the rigorous demands of laser diode testing. This state-of-the-art system is engineered with a modular design, allowing up to 10 laser diodes to be controlled independently within a single 19-inch instrument. This flexibility is further enhanced by the ability to combine multiple instruments, operated by a single PC, into a rack configuration. For those requiring a more compact setup, a half-width rack accommodating up to 4 plug-in units is available as an optional feature.

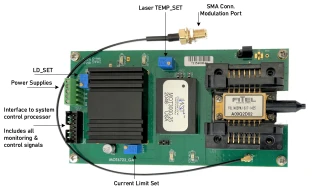

The LTBiS is specifically tailored for laser diode burn-in and life testing, ensuring reliability and performance over extended periods. The system comprises two main hardware components: the 19-inch mainframe, referred to as the master, and up to 10 plug-in units. Alternatively, a 9.5-inch wide master with up to 4 plug-in units can be utilized. The master unit is easily controlled via a serial interface, with a straightforward command structure that facilitates precise operation. An integrated external forward testing photodiode, connected through an external fiber loop, allows for seamless testing and monitoring, with both the photodiode and laser accessible via a front plate terminated by FC/APC.

The master control interface of the LTBiS is equipped with RS-232 connectivity, with an optional USB interface for enhanced versatility. The system is housed in a robust 19-inch rack, capable of accommodating up to 10 plug-in units, or a 9.5-inch rack for up to 4 units. The power supply is designed with redundancy in mind, featuring dual IEC-320 plugs supporting 110-230 V AC. Efficient cooling is ensured through a strategic airflow design, drawing air in from the bottom front side and expelling it from the back side. The backplane is engineered to accept the maximum number of plug-in units, ensuring scalability and adaptability to various testing requirements.

The LTBiS is built to operate under a range of environmental conditions, maintaining performance in non-condensing environments with temperatures ranging from +5°C to 50°C. The system's features include automatic recognition of plug-in units and separate control of each laser, supporting operation in ACC, APC modes, and PVI testing. The TEC setpoint is adjustable between -20° and 60°C, providing precise thermal management for optimal laser diode performance.

LTBiS Scalable Laser Diode Driver System

Specifications

| Control Interface: | RS-232 (USB optional) |

|---|---|

| Size: | 19 inch rack (84 TE), 4 HE |

| Size: | 9.5 inch rack (42 TE), 4 HE |

| Power Supply: | 110-230 V AC |

| Max Current (TEC): | 3 A |

| Operating Temperature: | +5°C ... 50°C |

| TEC Setpoint: | -20° ... 60°C |

| Maximum Compliance Voltage: | 2.9 V |

| Temperature Stability (TEC Setpoint): | 0.1°K |

| Current Stability (Iop): | 2 mA |

| Modulation: | 20 Hz minimum |

| Rise/Fall Time: | max. 1 µs |

| Max. Number Of Laser Diodes (BF-package): | 10 |

| Max. Operation Current/diode: | 2A |

Features

- Multi-Channel Control: The LTBiS can independently control up to 10 laser diodes within a single 19-inch instrument, offering flexibility and scalability for various applications.

- Modular Design: The system's modular architecture allows for easy expansion and integration, with options for a 9.5-inch rack that accommodates up to 4 plug-in units.

- Comprehensive Interface: Equipped with a digital electronic interface, the LTBiS can be controlled via RS-232 or optionally through USB, ensuring seamless communication and control.

- Redundant Power Supply: Features dual power supplies with IEC-320 plugs, supporting 110-230 V AC for reliable and continuous operation.

- Advanced Cooling System: Efficient airflow design with bottom front side intake and back side exhaust ensures optimal cooling of plug-in units.

- Flexible Operation Modes: Supports ACC, APC, and PVI-test modes, allowing for precise control over laser diode operations.

- Temperature Control: TEC setpoint ranges from -20°C to 60°C, with a temperature stability of 0.1°K after a 1-hour warm-up.

- High Precision: Offers setpoint resolutions of 0.5°K for LD TEC, 0.5 mA for current, and ~1 mW for power output, ensuring accurate and stable performance.

- Wide Wavelength Range: Supports a wavelength range of 750 nm to 1650 nm for power output testing via external photodiodes.

- Robust Connectivity: Features FC/APC fiber termination for secure and reliable connections.

- Automatic Recognition: Automatically detects and reads plug-in units, simplifying setup and configuration.

- Environmental Adaptability: Operates effectively in non-condensing environments with temperatures ranging from +5°C to 50°C.

- Comprehensive Monitoring: Provides detailed readings of operational current, monitor current, power output, heatsink temperature, and compliance voltage.

Applications

- Laser Diode Burn-In: Ensures long-term reliability testing under controlled conditions.

- Laser Diode Life Testing: Evaluates diode performance and operational lifetime.

- Production and R&D: Suitable for manufacturing quality control and research laboratories.

- Precision Characterization: Enables PVI tests and detailed monitoring of laser diode parameters.

- Environmental Stress Testing: Supports stable diode operation across wide temperature ranges.

Frequently Asked Questions

How many laser diodes can be controlled independently with the LTBiS system?

Can multiple LTBiS instruments be operated by one PC?

What are the available options for the rack?

What is the maximum operation current for the laser diodes?

What type of interface can be used for readout and control of the LTBiS system?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle