Description

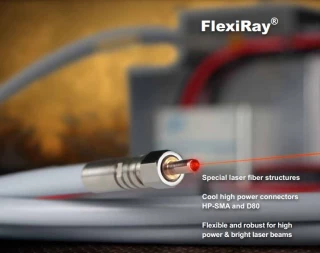

Introducing the FiberTech® LD-80 Laser Cables, a premium solution designed to meet the demanding needs of industrial laser applications. These cables are equipped with LD-80 freestanding fiber connectors and are encased in a robust PVC-coated steel-armored protection tube. This construction ensures durability and reliability, making them ideal for environments where resilience is paramount. The copper-based high-accuracy fiber ferrule is a standout feature, offering effective heat removal and ensuring high fiber centricity, which is crucial for optimal performance.

The innovative design of the FiberTech® LD-80 Laser Cables allows for efficient laser beam delivery, supporting power levels of up to 800 W. The all-silica step-index fiber, with a numerical aperture (NA) of 0.22, ensures superior performance across VIS-IR spectrums. For specialized applications, options with NA = 0.12 or graded-index fiber are available upon request. The connectors, measuring Ø 4 mm x 10 mm, come with an anti-twist key and a free-standing fiber tip, ensuring stability and precision in challenging conditions.

Every component of the FiberTech® LD-80 Laser Cables is meticulously crafted for excellence. All copper alloy parts enhance heat dissipation, while the fiber centricity of less than 5 µm from core to ferrule guarantees precision and accuracy. The squarelock, green PVC-coated protection tube, along with metal connector cuffs, provides robust protection and electrical isolation from end to end. This comprehensive design ensures that the FiberTech® LD-80 Laser Cables deliver unmatched performance and reliability in industrial laser applications.

LD80 Laser Cable - FCL30-90200-2000

Specifications

| Fiber Core Diameter: | 1000 um |

|---|---|

| Cable Length: | 2 m |

| Average Laser Power: | 800 W |

| Numerical Aperture (NA): | 0.22 |

| Connector Size: | Ø 4 mm x 10 mm |

| Fiber Centricity: | < 5 µm |

| Protection Tube: | PVC-coated steel-armored |

| Electrical Isolation: | from end to end |

Features

- LD-80 Freestanding Fiber Connectors: Ensures reliable and efficient laser beam delivery.

- PVC Coated Steel-Armored Protection Tube: Provides robust protection and durability.

- High-Accuracy Copper-Based Fiber Ferrule: Enhances heat removal and ensures high fiber centricity.

- Laser Beam Delivery: Suitable for delivering laser beams of up to 800 W.

- VIS-IR All-Silica Step-Index Fiber: Features a numerical aperture (NA) of 0.22, with options for NA = 0.12 and graded-index fiber available upon request.

- Connector Specifications: Ø 4 mm x 10 mm connectors with key (anti-twist) and free-standing fiber tip, secured with a hex nut.

- Improved Heat Removal: All copper alloy parts contribute to efficient heat dissipation.

- Fiber Centricity: Maintains fiber core to ferrule centricity of less than 5 µm.

- Squarelock Protection Tube: Comes with a green PVC coating for added protection.

- Metal Connector Cuffs: Ensures secure attachment of connectors to the cable.

- Electrical Isolation: Provides complete electrical isolation from end to end.

- Available Fiber Core Sizes: Options include 100 µm, 200 µm, 400 µm, 600 µm, 800 µm, and 1000 µm.

- Available Cable Lengths: Choose from 2 m, 3 m, and 5 m lengths to suit your needs.

Applications

- Industrial Laser Systems: Ideal for high-power laser beam delivery in manufacturing processes.

- Laser Cutting and Welding: Supports precision cutting and welding applications with power up to 800 W.

- Medical Laser Devices: Suitable for surgical laser systems requiring robust and safe cables.

- Research and Laboratory Setups: Provides stable and reliable laser transmission for experimental optics.

- Laser Machining: Enhances performance in engraving, marking, and micromachining operations.

Frequently Asked Questions

What is the composition of the LD80 Laser Cable?

What is the fiber core diameter of the LD80 Laser Cable?

What is the average laser power that the LD80 Laser Cable can handle?

What is the LD80 Laser Cable used for?

What is the maximum length of the LD80 Laser Cable?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle