Description

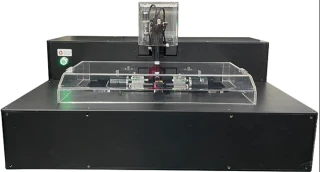

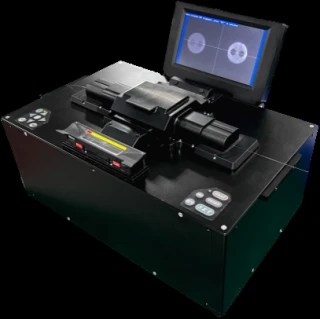

Small Special Fiber Splicer (XQ7230B)

The XQ7230B is an innovative small special fiber splicing system developed by SHENZHEN OSCOM TECHNOLOGY CO., LTD. This advanced system utilizes an electric heat source, making it a highly efficient solution for the splicing of various optical fiber products.

Designed with precision and versatility in mind, the XQ7230B fiber splicer is ideal for a range of splicing applications, including the creation of combiners, fiber bundles, coarse fibers, and the integration of fibers with end caps. One of the standout features of the XQ7230B is its ability to handle a wide range of fiber sizes, from Φ 400μm to Φ 800μm, with customization options available for sizes ranging from Φ 125μm to Φ 1200μm or even larger if required. This flexibility makes it a valuable tool for professionals dealing with diverse splicing needs, ensuring that the system can adapt to specific project requirements with ease.

The XQ7230B fiber splicer's electric heat source splicing capability is complemented by its end cap splicing functionality, providing a comprehensive solution for fiber splicing tasks. With its robust design and cutting-edge technology, the XQ7230B stands out as a reliable and efficient choice for those seeking precision and adaptability in their fiber splicing operations.

Small Special Fiber Splicer with Electric Heat Source XQ7230B

Specifications

| Supported Fiber Diameter: | 120 – 1200 um |

|---|---|

| Accuracy Of Z Axis: | 1μm |

| Weight: | 42Kg |

| Dimensions (L×W×H): | 470x395x360 mm |

| Power Supply: | AC100-240V/50-60Hz |

| Operating Environment: | Temperature: 0-40℃ / Humidity: 5-95%RH |

| Splicing Mode: | Standard splicing, user-defined splicing |

| Clamping Method: | Magnetic adhesion |

| Alignment Mode: | Automatic alignment of cladding |

| Travel Ranges Of Z Axis: | 40mm |

| Axis Range Of θ Axis: | ±5° |

| Axis Accuracy Of θ Axis: | 0.1° |

| Travel Ranges Of X/Y Axis: | ±5.5mm |

| Axis Accuracy Of X/Y Axis: | 1μm |

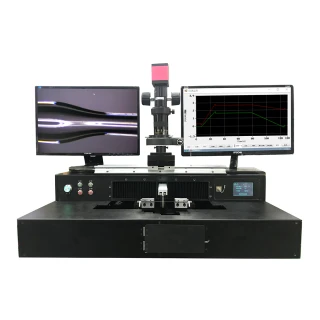

| Panoramic View: | X/Y independent side imaging |

| CCD View: | 2.8x2.1mm or customization |

| Heat Source Temperature Field: | 800-1800℃ |

| Heat Source: | Electric heat source |

Features

- Compact Design: The XQ7230B is a small, specialized fiber splicing system, perfect for various optical fiber products.

- Versatile Applications: Ideal for high power combiner splicing, fiber bundles, coarse fibers, and end caps.

- Customizable Fiber Sizes: Accepts fiber sizes from Φ 400μm to Φ 800μm, with customization available from Φ 125μm to over Φ 1200μm.

- Electric Heat Source: Utilizes an electric heat source with a temperature field of 800-1800℃ for efficient splicing.

- Precision Alignment: Features automatic alignment of cladding with a magnetic adhesion clamping method.

- High Accuracy: Offers axis accuracy of 1μm for X/Y and Z axes, and 0.1° for the θ axis.

- Panoramic and CCD View: Provides a panoramic view with X/Y independent side imaging and a CCD view of 2.8x2.1mm, customizable.

- Robust Operating Environment: Operates efficiently in temperatures from 0-40℃ and humidity levels of 5-95%RH.

- Flexible Power Supply: Compatible with AC100-240V/50-60Hz power sources.

- Compact Dimensions: Measures 470x395x360 mm and weighs 42Kg, making it easy to integrate into various setups.

Applications

- High Power Combiner Splicing: Ideal for splicing high power combiners, ensuring efficient and reliable connections.

- Fiber Splicing: Suitable for various fiber splicing applications, including the splicing of fiber bundles and coarse fibers.

- End Cap Splicing: Facilitates the splicing of fibers and end caps, enhancing the durability and performance of optical fiber products.

- Electric Heat Source Splicing: Utilizes an electric heat source for precise and consistent splicing, accommodating a wide range of fiber sizes from Φ125μm to Φ1200μm, with customization available for larger sizes.

Frequently Asked Questions

What is the XQ7230B Small Special Fiber Splicer used for?

What are the accepted fiber sizes for the XQ7230B?

What is the heat source used in the XQ7230B?

What is the alignment mode of the XQ7230B?

What are the dimensions and weight of the XQ7230B?

What is the operating environment for the XQ7230B?

What power supply does the XQ7230B require?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle