Description

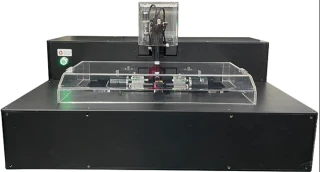

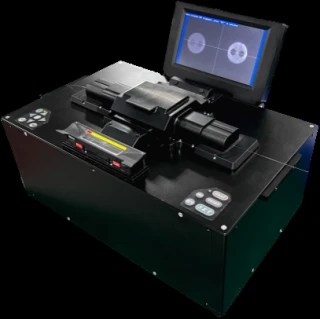

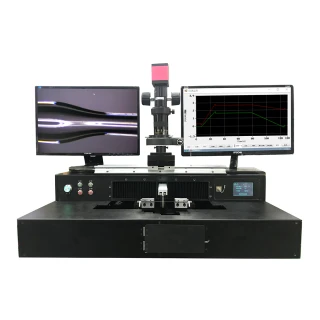

XQ7210M12 is a large-diameter fiber splicer with CO2 laser as the heat source which is designed independently by OSCOM Technology. The splicer can splice 80μm-2500μm fiber or glass rod quickly, accurately and stably. It mainly used for the splicing of QBH fiber end cap, optical combiner fiber bundles, special fiber, the tapering of glass tube, and the processing of fiber ball lens, low melting point fiber, etc. It is multifunctional, easy to use and has flexible applications.

OSCOM TECHNOLOGY - M12 CO2 Laser Splicer - XQ7210M12

Specifications

| Supported Fiber Diameter: | 80 – 2500 um |

|---|---|

| Item Name: | CO2 Laser Splicer |

| Attach Feature: | Without tapering function/With tapering function |

| Laser Power: | 30W |

| Laser Wavelength: | 10.6μm |

| Laser Type: | CO2 |

| Laser Optical Path: | Approximate to the shape of cross |

| Fiber Cladding Splicing Range: | 80-2500μm (Customizable) |

| End Cap Clamping Range: | 1mm/1.8mm/2mm/8mm (Typical) |

| Fiber Fixing Method: | Magnetic adhesion |

| Alignment Method: | Cladding automatic alignment |

| Fiber Splicing Method: | Laser heating |

| CCD View: | 2.8x2.1mm or customized |

| X/Y Axis Alignment Resolution: | 0.1μm |

| X/Y Axis Movement Range: | ≥11mm |

| θ Axis Alignment Resolution: | 0.1° |

| θ Axis Alignment Range: | ±4.5° |

| Z Axis Resolution: | 0.1μm |

| Z Axis Movement Range: | 150mm (Unilateral 75mm) |

| Splicing Procedure: | Standard splicing/Misplaced splicing/User-defined splicing |

| Tapering Type: | Unilateral tapering/Bilateral tapering |

| Tapering Speed: | 0-2000μm/s |

| Tapering Length: | Same direction 75mm/Reverse 150mm |

| Operating Environment: | Temperature: 0-40℃/Humidity: 5-95%RH |

| Power Supply: | AC100-240V/50-60Hz |

| Dimensions (LxWxH): | 880x600x1250mm |

| Weight: | 150Kg |

Features

- The distribution of the heating is approximate to the shape of cross.

- Can splice various shapes of optical fiber end caps with high quality.

- Can adjust dynamically the position of the multidimensional fiber or end caps.

- Dedicated end cap holder, the clamping diameter can be customized according to customers’ needs.

- The openness of the splicing procedure is extremely high.

- The splicing process is controlled by professional microscope magnification imaging system and software system.

- High-precision drive motor and guide rail system.

Applications

- QBH Fiber Endcap Splicing: Efficiently splices QBH fiber endcaps with precision and stability.

- Optical Combiner Fiber Bundles: Ideal for splicing optical combiner fiber bundles with high quality.

- Special Fiber Applications: Suitable for splicing various types of special fibers.

- Glass Tube Tapering: Performs tapering of glass tubes with accuracy and control.

- Fiber Ball Lens Processing: Capable of processing fiber ball lenses for precise applications.

- Low Melting Point Fiber: Handles splicing of low melting point fibers effectively.

Frequently Asked Questions

What is the M12 CO2 Laser Splicer (XQ7210M12)?

The XQ7210M12 is a large-diameter fiber splicer using a CO2 laser as the heat source, designed by OSCOM Technology. It is used for splicing fibers or glass rods ranging from 80μm to 2500μm quickly, accurately, and stably.

What are the main applications of the XQ7210M12 laser fiber splicer?

The XQ7210M12 is used for splicing QBH fiber end caps, optical combiner fiber bundles, special fibers, tapering of glass tubes, processing fiber ball lenses, and low melting point fibers.

What is the laser power and wavelength of the XQ7210M12 fiber splicer?

The laser power is 30W, and the laser wavelength is 10.6μm.

How does the splicer align fibers during splicing?

The XQ7210M12 uses cladding automatic alignment method for fiber alignment.

What is the operating environment for the XQ7210M12 fiber splicer?

The operating environment for the XQ7210M12 is a temperature range of 0-40℃ and humidity of 5-95% RH.

What power supply does the XQ7210M12 require?

The XQ7210M12 requires an AC power supply of 100-240V and 50-60Hz.

What are the dimensions and weight of the XQ7210M12 splicer?

The dimensions of the XQ7210M12 are 880x600x1250mm, and it weighs 150Kg.

Similar Products

Graphite Fiber Splicer with Precision Alignment and Heating XQ7240

Shenzhen Oscom Technology Co., Ltd

Polarization-Maintaining Large Diameter Fiber Splicer XQ7260C

Shenzhen Oscom Technology Co., Ltd

CO2 Laser Splicer for Large-Diameter Polarization-Maintaining Fiber XQ7210P

Shenzhen Oscom Technology Co., Ltd

Small Special Fiber Splicer with Electric Heat Source XQ7230B

Shenzhen Oscom Technology Co., Ltd

OSCOM TECHNOLOGY - Array CO2 Laser Splicer (XQ7221)

Shenzhen Oscom Technology Co., Ltd

OSCOM TECHNOLOGY - Two Electrodes Polarization-Maintaining Fiber Splicer - XQ7260P2

Shenzhen Oscom Technology Co., Ltd

OSCOM TECHNOLOGY - Large Diameter Fiber Splicer - XQ7260M2

Shenzhen Oscom Technology Co., Ltd

OSCOM TECHNOLOGY - Optical Combiner Fiber Taper - XQ7140

Shenzhen Oscom Technology Co., Ltd

OSCOM TECHNOLOGY - Special Fiber Splicer - XQ7230A1

Shenzhen Oscom Technology Co., Ltd

OSCOM TECHNOLOGY - Multi-Mode Fiber Taper - XQ7180

Shenzhen Oscom Technology Co., Ltd

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle