Description

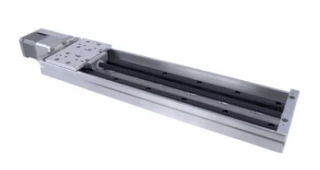

The X-LSM-SV2 is a state-of-the-art motorized linear stage engineered for high-vacuum environments. This advanced device integrates a built-in controller, making it a stand-alone unit that requires only a standard 24 V or 48 V power supply for operation. Its compact design, with a height of just 21 mm, makes it ideal for applications demanding a minimal footprint. The X-LSM-SV2 is crafted from vacuum-compatible materials, which significantly reduce outgassing and enable quicker pump down times, ensuring efficient operation in vacuum conditions.

Zaber's X-LSM-SV2 Series is designed to offer seamless connectivity and versatility. These stages can be easily connected to the RS-232 or USB port of any computer and are capable of being daisy-chained with other Zaber products. This feature not only simplifies the setup process but also allows for power sharing among multiple X-Series products, reducing the need for multiple power supplies. The ease of integration and operation embodies Zaber's commitment to delivering 'plug and play' solutions.

With its high thrust and speed capabilities, the X-LSM-SV2 is built to handle demanding tasks with precision. It boasts a travel range of up to 203.2 mm and can achieve speeds of up to 100 mm/s. The device is engineered to support a load capacity of up to 10 kg, making it a robust choice for various industrial and scientific applications. Its precision lead screw drive system and needle roller bearing guide type ensure smooth and accurate motion control, while the device's compact size does not compromise its performance.

The X-LSM-SV2 is a testament to Zaber's dedication to innovation in motion control technology, providing users with a reliable, high-performance solution for their vacuum application needs. Its user-friendly design, combined with advanced functionality, makes it an excellent choice for those seeking to simplify and enhance their motion control systems.

High Vacuum Motorized Linear Stage X-LSM200A-SV2

Specifications

| Number Of Axes: | One |

|---|---|

| Vacuum Grade: | 10 mbar |

| Travel Range: | 25, 50, 100, 150, 200 mm |

| Load Capacity: | 10 kg |

| Maximum Speed: | 100 mm/s |

| Power Supply: | 24-48 VDC |

| Microstep Size (Default Resolution): | 0.047625 µm |

| Travel Range: | 203.2 mm |

| Repeatability: | < 1 µm |

| Minimum Speed: | 0.000029 mm/s |

| Speed Resolution: | 0.000029 mm/s |

| Vertical Runout: | < 8 µm |

| Horizontal Runout: | < 12 µm |

| Linear Motion Per Motor Rev: | 0.6096 mm |

| Motor Steps Per Rev: | 200 |

| Motor Rated Current: | 800 mA/phase |

| Inductance: | 3.5 mH/phase |

Features

- Vacuum Compatibility: Suitable for environments up to 10-6 Torr.

- Travel Options: Available in 25, 50, 100, 150, and 200 mm travel ranges.

- Load Capacity: Can handle loads up to 10 kg.

- Performance: Achieves speeds up to 100 mm/s and thrust up to 35 N.

- Integrated Controller: Features a built-in controller for seamless operation.

- Daisy-Chain Capability: Easily daisy-chains with other Zaber products using only 4 feedthrough wires via serial port (with X-PIB adaptor).

- Compact Design: At just 21 mm high, ideal for applications requiring a small profile.

- Plug and Play: Designed for easy setup and operation with minimal outgassing for faster pump down times.

- Connectivity: Connects to RS-232 or USB ports; daisy-chain shares power for multiple units.

- Precision: Offers a microstep size of 0.047625 µm and repeatability of less than 1 µm.

- Durability: Constructed with vacuum-compatible materials and needle roller bearings for stability.

- Power Requirements: Operates with a standard 24 V or 48 V power supply.

- Communication: Supports Zaber ASCII and Zaber Binary protocols.

- Mechanical Drive System: Precision lead screw for accurate linear motion.

Applications

- Vacuum Research Systems: Ideal for precise positioning in vacuum chambers.

- Semiconductor Manufacturing: Enables accurate wafer alignment under vacuum conditions.

- Scientific Instrumentation: Supports high-precision motion in optical and analytical devices.

- Automated Testing: Suitable for integration in automated vacuum test setups.

Material Science: Facilitates controlled sample positioning in vacuum environments.

Frequently Asked Questions

What is the load capacity of the X-LSM-SV2?

What is the maximum speed of the X-LSM-SV2?

Can the X-LSM-SV2 be controlled by a computer?

What is the height of the X-LSM-SV2?

What materials is the X-LSM-SV2 made of?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle