Description

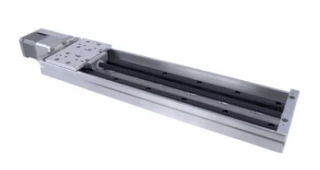

Zaber's X-LSM-SV2 Series introduces a cutting-edge solution for precision motion control in vacuum environments. These motorized linear stages are designed with a built-in controller, making them a streamlined choice for high-vacuum applications. The compact and robust design ensures reliability and versatility, accommodating a wide range of operational needs with travel options ranging from 25 mm to 200 mm. With a load capacity of up to 10 kg and speeds reaching up to 100 mm/s, the X-LSM-SV2 Series delivers exceptional performance in a small footprint.

Engineered for seamless integration, these stages can be connected to the RS-232 or USB ports of any computer, allowing for straightforward daisy-chaining with other Zaber products. This feature not only simplifies setup but also optimizes power distribution, as multiple units can share a single power supply. The innovative design requires only four feedthrough wires to control all units in the chain, streamlining connectivity and reducing clutter in complex systems.

The X-LSM-SV2 Series is crafted from vacuum-compatible materials to minimize outgassing, ensuring faster pump-down times and superior performance in vacuum conditions. Standing at just 21 mm high, these stages are ideal for applications requiring a low-profile solution without sacrificing functionality or precision. Zaber’s commitment to user-friendly, 'plug and play' design principles ensures that the X-LSM-SV2 Series is not only easy to set up but also intuitive to operate, making it a preferred choice for professionals seeking reliable and efficient motion control solutions.

High Vacuum Motorized Linear Stage X-LSM150A-SV2

Specifications

| Number Of Axes: | One |

|---|---|

| Vacuum Grade: | 10 mbar |

| Vacuum Compatibility: | 10-6 Torr |

| Travel Range: | 152.4 mm |

| Load Capacity: | 10 kg |

| Maximum Speed: | 24 mm/s |

| Power Supply: | 24-48 VDC |

| Microstep Size: | 0.047625 µm |

| Accuracy (unidirectional): | 46 µm |

| Vertical Runout: | < 8 µm |

| Horizontal Runout: | < 12 µm |

| Maximum Current Draw: | 350 mA |

| Motor Rated Current: | 800 mA/phase |

| Inductance: | 3.5 mH/phase |

Features

- Vacuum Compatibility: Suitable for environments with vacuum levels up to 10-6 Torr.

- Travel Options: Available in 25, 50, 100, 150, and 200 mm travel ranges.

- Load Capacity: Supports up to 10 kg of load.

- Speed and Thrust: Capable of speeds up to 100 mm/s and thrusts up to 35 N.

- Built-in Controller: Integrated controller allows for easy daisy-chaining with other Zaber products.

- Minimal Wiring: Requires only 4 feedthrough wires for control via serial port with an X-PIB adaptor.

- Compact Design: At only 21 mm high, it is ideal for applications requiring a small profile.

- Power Supply: Operates with a standard 24 V or 48 V power supply.

- Connectivity: Connects to RS-232 or USB ports, facilitating integration with computer systems.

- Shared Power: Daisy-chain configuration allows multiple devices to share a single power supply.

- Precision and Accuracy: Offers a microstep size of 0.047625 µm and unidirectional accuracy of 46 µm.

- Repeatability: Less than 1 µm, ensuring consistent performance.

- Low Backlash: Backlash is under 3 µm, enhancing precision.

- Speed Resolution: As fine as 0.000029 mm/s for precise control.

- Durability: Constructed with vacuum-compatible materials to minimize outgassing and reduce pump down times.

- Guide Type: Features a needle roller bearing for smooth motion.

- Mechanical Drive System: Uses a precision lead screw for reliable operation.

- Motor Type: Equipped with a stepper motor (2 phase) for accurate positioning.

Applications

- Vacuum Motion Control: Ideal for linear positioning tasks in high vacuum environments for research and development.

- Precision Automation Systems: Enhances automated inspection, assembly, and alignment processes with reliable micro-positioning.

- Optical Alignment: Suitable for precise alignment of optics within vacuum chambers.

- Semiconductor and Material Science: Supports wafer positioning and materials analysis under vacuum conditions.

- Multi-Axis Motion Systems: Easily integrates into complex setups with other Zaber stages for synchronized motion control.

Frequently Asked Questions

What is the load capacity of the X-LSM-SV2?

Can the X-LSM-SV2 be controlled by a computer?

What is the maximum speed and thrust of the X-LSM-SV2?

Can multiple X-LSM-SV2 units share a single power supply?

What is the height of the X-LSM-SV2?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle