Description

The Rigel g400 from Powerlase Photonics is a high-power, diode-pumped short pulse laser designed for industrial applications requiring precision and reliability. This Q-switched, intra-cavity frequency-doubled laser delivers impressive average powers of up to 400 W, making it a powerhouse in its class. Operating at a wavelength of 532 nm, the Rigel g400 provides an unpolarized multi-mode beam, ensuring versatility and efficiency in various demanding environments.

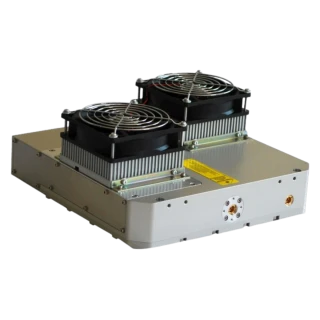

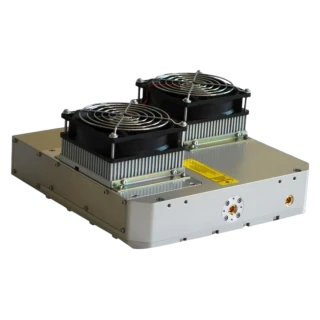

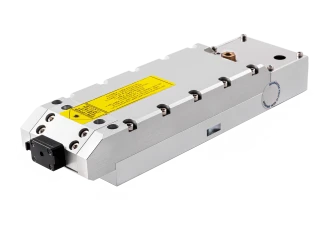

Featuring a rugged head design, the Rigel g400 is built to withstand the rigors of high-volume industrial use. Its state-of-the-art universal control system architecture ensures seamless integration and synchronization with OEM equipment and process lines, making it an ideal choice for manufacturers seeking to enhance their production capabilities. The robust construction and advanced technology of the Rigel g400 guarantee consistent performance and longevity, even in the most challenging conditions.

Powerlase Photonics has engineered the Rigel g400 with user convenience in mind, offering ease of use and straightforward operation. The laser's design emphasizes reliability and stability, providing peace of mind to operators who depend on consistent laser performance for their processes. With its high power output and advanced features, the Rigel g400 is a valuable asset for industries aiming to optimize their operations and achieve superior results.

Rigel g400 High Power Diode Pumped Short Pulse Laser

Specifications

| Avg. Power: | 400 W |

|---|---|

| Wavelength: | 532 nm |

| Repetition Rate: | 10 – 30 kHz |

| Spatial Mode (M^2): | 28 |

| Pulse Duration: | 75 ns |

| Pulse-to-Pulse Stability (RMS): | 1 % |

| Cooling: | Water-to-Water |

| Pulse Energy: | 40 mJ |

| Divergence: | 6 mrad |

| Power Stability: | 0.5% |

| Typical Fibre Core: | 600 μm |

| Supply Voltage: | 3-phase N+E, 220 or 400 VAC (±10%) |

| Supply Frequency: | 50 or 60 Hz |

| Nominal Power Consumption: | 20 kVA |

| Gas Purge: | N2 or Air (Grade N5.0, <1 ppm THC) |

| Laser Dimensions: | 1900 x 600 x 235 mm |

| Control Rack Dimensions: | 1195 x 600 x 970 mm |

| Environmental Conditions: | Temp 15 - 32°C and RH <60% (90% max, non condensing) |

Features

- High Power Output: The Rigel g400 delivers high average powers up to 400 W in an unpolarized multi-mode beam at a wavelength of 532 nm.

- Pulse Energy: Achieves pulse energy up to 40 mJ, suitable for demanding applications.

- Exceptional Beam Quality: With an M2 value of 28, ensuring excellent stability for precision tasks.

- Versatile Output Options: Offers optional dual polarized outputs, single unpolarized output, and fiber delivery in round or square configurations.

- Repetition Frequency Optimization: Optional feature for enhanced performance tailored to specific needs.

- Robust Design: Features a well-proven rugged head design for durability in industrial environments.

- Universal Control System: State-of-the-art architecture allows for simple synchronization with OEM equipment and process lines.

- Industrial Applications: Ideal for photovoltaic processing, poly-silicon annealing, hard materials processing, micro machining, and Ti:Sapphire pumping.

- Environmental and Facility Requirements: Operates efficiently under temperature conditions of 15 - 32°C and relative humidity <60% (90% max, non-condensing).

Applications

- Photovoltaic Processing

- Poly-Silicon Annealing

- Hard Materials Processing

- Micro Machining

- Ti:Sapphire Pumping

Frequently Asked Questions

What is the Rigel g400 DPSS Green Laser?

What are the applications of the Rigel g400 DPSS Green Laser?

What are the dimensions of the Rigel g400 DPSS Green Laser?

What are the facility requirements for the Rigel g400 DPSS Green Laser?

Is the Rigel g400 DPSS Green Laser safe to use?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle