Description

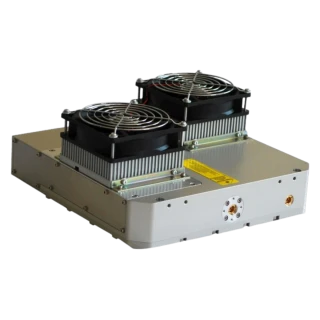

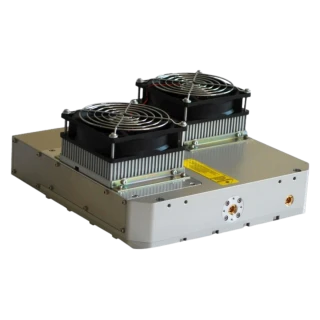

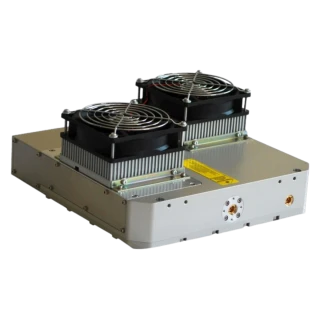

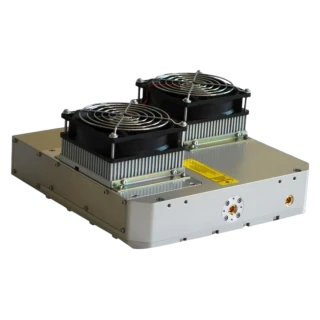

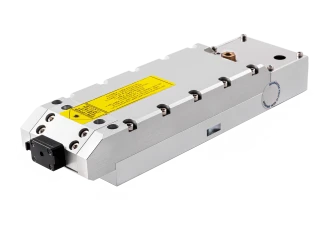

The **AOPico™ Series** of Industrial Picosecond Lasers from Advanced Optowave™ represents a significant advancement in laser technology, offering unparalleled performance for a variety of industrial applications. These cutting-edge lasers are designed to deliver high-precision, high-speed micro-machining capabilities, making them ideal for industries that demand the utmost in precision and efficiency.

The AOPico™ Series stands out in the market with its advanced technology and robust design, ensuring a low cost of ownership while maintaining excellent beam quality with an M² value of less than 1.3. This series is available in three different wavelengths—IR, Green, and UV—catering to a wide range of industrial needs. With up to 45W average power and pulse durations of just 7 picoseconds, these lasers are engineered for optimal performance and reliability.

The AOPico™ Series is particularly suited for demanding tasks such as thin-film ablation, medical device manufacturing, and semiconductor processing. Its capability for brittle material cutting, drilling, dicing, and sub-surface marking further underscores its versatility and precision. The AOPico™ Series is not only about power and precision but also about reliability and ease of use. With a highly reliable design and features such as a burst mode option, these lasers are built to perform consistently under various conditions.

The operational temperature range of 15 to 30°C and a humidity range of 20 to 80% non-condensing ensure that these lasers can be used in a wide array of environments. Furthermore, the series complies with international standards such as CDRH, ROHS, and CE, ensuring safety and quality in every unit. Whether for polymer processing or wafer scribing, the AOPico™ Series is a trusted choice for professionals seeking cutting-edge laser solutions.

AOPico 532 5-100 Industrial Picosecond Lasers for Precision Micro-machining

Specifications

| Avg. Power: | 5 W |

|---|---|

| Wavelength: | 532 nm |

| Repetition Rate: | 1 – 100 kHz |

| Spatial Mode (M^2): | 1.3 |

| Pulse Duration: | 0.007 ns |

| Pulse-to-Pulse Stability (RMS): | 2 % |

| Cooling: | Water-to-Water |

| Energy (µJ): | 100 |

| Beam Quality (M2): | <1.3 |

| Beam Roundness (%): | >85 |

| Beam Diameter (mm): | ~1.0 |

| Beam Divergence (mRad): | <0.7 |

| Point Stability (µrad/ºC): | <50 |

| Polarization Ratio: | 100:1 Linear, Horizontal |

| Polarization Ratio: | 100:1 Linear, Vertical |

Features

- Advanced Optowave™ Diode-Pumped Solid-State Laser Solutions: Providing cutting-edge technology for industrial applications.

- Versatile Wavelength Options: Available in IR (1064 nm), Green (532 nm), and UV (355 nm) to suit diverse industrial needs.

- High Average Power: Offers up to 45W average power for demanding applications.

- Ultra-Short Pulse Durations: 7 ps pulse durations for precision micro-machining.

- Excellent Beam Quality: M2 < 1.3 ensures superior beam performance.

- Highly Reliable Design: Engineered for durability and consistent performance.

- Burst Mode Option: Enhance processing capabilities with burst mode functionality.

- Wide Range of Applications: Ideal for thin-film ablation, medical device manufacturing, polymer processing, semiconductor processing, wafer scribing, and more.

- Efficient and Cost-Effective: Lowest cost of ownership in the industry.

- Compliance and Safety: Meets CDRH, ROHS, and CE compliance standards.

- Compact and Lightweight Design: Laser head dimensions of 25 x 15 x 7 in (585 x 381 x 179 mm) and weight of 70 lbs (32 kg).

- Easy Integration: RS-232 communication and water cooling for seamless operation.

- Robust Environmental Specifications: Operational temperature range of 15 to 30°C and storage temperature range of -20 to 50°C.

- Flexible Power Requirements: Input voltage range of 90 to 260 VAC and line frequency of 50 or 60 Hz.

Applications

- Thin-Film Ablation

- Medical Device Manufacturing

- Polymer Processing/Machining

- Semiconductor/PV Processing/Wafer Scribing

- High-Precision, High-Speed Micro-machining

- Brittle Material Cutting, Drilling, Dicing & Sub-Surface Marking

Frequently Asked Questions

What applications is the AOPico 532 5-100 suitable for?

What is the warranty coverage for the AOPico 532 5-100?

What is the AOPico 532 5-100?

What is the average power of the AOPico 532 5-100?

What is the pulse duration of the AOPico 532 5-100?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle