Description

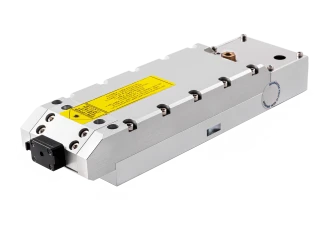

The AOPicoTM Series of Industrial Picosecond Lasers by Advanced OptowaveTM represents a breakthrough in diode-pumped solid-state laser solutions. Engineered for precision and efficiency, these lasers are designed to meet the demands of various high-tech industries. With a focus on delivering superior performance and reliability, the AOPicoTM Series is the epitome of innovation in laser technology.

At the heart of the AOPicoTM Series is its ability to cater to a wide range of industrial applications, from thin-film ablation to medical device manufacturing, and more. These lasers are adept at handling complex tasks such as polymer processing, semiconductor and PV processing, wafer scribing, and high-precision micro-machining. The series is particularly suited for brittle material cutting, drilling, dicing, and sub-surface marking, making it an invaluable tool for industries requiring meticulous precision and speed.

The AOPicoTM Series is available in infrared, green, and ultraviolet wavelengths, offering flexibility and adaptability to specific industrial needs. With up to 45W of average power and pulse durations of just 7 picoseconds, these lasers deliver exceptional beam quality with M2 values of less than 1.3. The design prioritizes reliability and cost-effectiveness, ensuring the lowest cost of ownership in the industry. Whether in burst mode or continuous operation, the AOPicoTM Series stands out for its stable performance and consistent output, backed by Advanced Optowave's commitment to continuous product improvement.

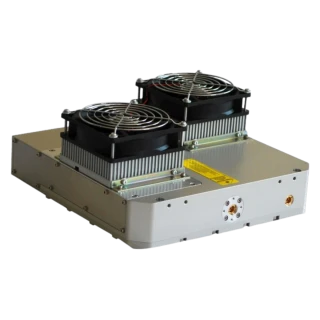

AOPico 532 12-200 Industrial Picosecond Lasers for Precision Micro-machining

Specifications

| Avg. Power: | 12 W |

|---|---|

| Wavelength: | 532 nm |

| Repetition Rate: | 1 – 200 kHz |

| Spatial Mode (M^2): | 1.3 |

| Pulse Duration: | 0.007 ns |

| Pulse-to-Pulse Stability (RMS): | 2 % |

| Cooling: | Water-to-Water |

| Average Power: | 45 W |

| Energy: | 125 µJ |

| Specified Repetition Rate: | 1000 kHz |

| Beam Roundness: | >85% |

| Beam Diameter: | ~0.5 mm |

| Beam Divergence: | <0.35 mRad |

| Point Stability: | <50 µrad/ºC |

| Polarization Ratio: | 100:1 Linear, Horizontal |

| Operational Temperature Range: | 15 to 30 ºC |

| Storage Temperature Range: | -20 to 50 ºC |

| Input Voltage: | 90 to 260 VAC |

| Laser Head Dimensions: | 25 x 15 x 7 in (585 x 381 x 179 mm) |

| Laser Head Weight: | 70 lbs (32 kg) |

| Laser Controller Dimensions: | 19 x 17 x 7 in (482 x 432 x 178 mm) |

| Laser Controller Weight: | 30 lbs (13.6 kg) |

Features

- Industrial Picosecond Lasers: The AOPicoTM Series offers advanced picosecond laser technology for industrial applications.

- Advanced OptowaveTM Solutions: Utilizing diode-pumped solid-state laser solutions for superior performance.

- Versatile Wavelength Options: Available in IR (1064 nm), Green (532 nm), and UV (355 nm) wavelengths to suit diverse applications.

- High Power Output: Delivers up to 45W of average power for demanding tasks.

- Precision Pulse Duration: Offers pulse durations of just 7 picoseconds for high-precision applications.

- Exceptional Beam Quality: Beam quality of M2 < 1.3 ensures excellent performance.

- Cost-Effective Operation: Designed to provide the lowest cost of ownership in the industry.

- Reliable and Robust Design: Engineered for high reliability and consistent performance.

- Burst Mode Option: Includes a burst mode for enhanced application flexibility.

- Wide Range of Applications: Ideal for thin-film ablation, medical device manufacturing, polymer processing/machining, semiconductor/PV processing, wafer scribing, high-precision micro-machining, and brittle material cutting, drilling, dicing, and sub-surface marking.

- Stable and Accurate: Features pulse-to-pulse stability of <2% RMS and average power stability of <3% over 12 hours.

- Operational Flexibility: Operates within a temperature range of 15 to 30ºC and humidity range of 20 to 80% non-condensing.

- Compliance and Safety: Meets CDRH, ROHS, and CE compliance standards.

- Convenient Communication and Cooling: Equipped with RS-232 communication and water cooling for optimal performance.

Applications

- Thin-Film Ablation

- Medical Device Manufacturing

- Polymer Processing/Machining

- Semiconductor/PV Processing/Wafer Scribing

- High-Precision, High-Speed Micro-machining

- Brittle Material Cutting, Drilling, Dicing & Sub-Surface Marking

Frequently Asked Questions

What are the applications of the AOPico 532 12-200?

What is the warranty coverage for the AOPico 532 12-200?

What is the AOPico 532 12-200?

What is the output power of the AOPico 532 12-200?

What is the pulse duration of the AOPico 532 12-200?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle