Description

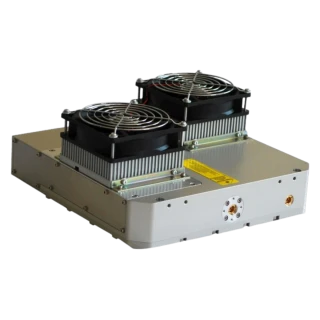

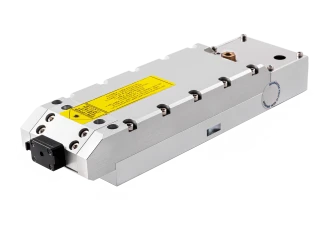

The **AOPico™ Series** of Industrial Picosecond Lasers from Advanced Optowave™ represents a cutting-edge solution in the realm of precise laser technology. These diode-pumped solid-state lasers offer exceptional performance for industrial applications, delivering unparalleled precision and efficiency.

The series is designed to meet the rigorous demands of modern manufacturing, providing a reliable and cost-effective option for businesses looking to enhance their production capabilities. One of the standout features of the **AOPico™ Series** is its adaptability across various wavelengths, including IR, Green, and UV, allowing for versatile application opportunities. With up to 45W of average power and pulse durations as short as 7 picoseconds, these lasers ensure high-speed micro-machining and exceptional beam quality with an M² value of less than 1.3.

The robust design of these lasers emphasizes reliability, making them a trusted choice for industries that require consistent performance and minimal downtime. The **AOPico™ Series** lasers are engineered for high-precision tasks such as thin-film ablation, medical device manufacturing, and polymer processing. They also excel in semiconductor processing, wafer scribing, and brittle material cutting.

The lasers' ability to deliver precise, high-speed results is complemented by their low cost of ownership, making them a smart investment for companies seeking to optimize their manufacturing processes. With compliance to CDRH, ROHS, and CE standards, these lasers not only meet but exceed industry expectations for safety and performance.

AOPico 355 3-100 Industrial Picosecond Lasers for Precision Micro-machining

Specifications

| Avg. Power: | 3 W |

|---|---|

| Wavelength: | 355 nm |

| Repetition Rate: | 3 – 100 kHz |

| Spatial Mode (M^2): | 1.3 |

| Pulse Duration: | 0.007 ns |

| Pulse-to-Pulse Stability (RMS): | 2 % |

| Cooling: | Water-to-Water |

| Energy (µJ): | 100 |

| Repetition Rate (kHz): | Single Shot to 1000 |

| Beam Quality (M2): | <1.3 |

| Beam Roundness (%): | >85 |

| Beam Diameter (mm): | ~1.0 |

| Beam Divergence (mRad): | <1.3 |

| Point Stability (µrad/ºC): | <50 |

| Polarization Ratio: | 100:1 Linear, Horizontal |

| Polarization Ratio: | 100:1 Linear, Vertical |

| Polarization Ratio: | 100:1 Linear, Horizontal |

Features

- Industrial Picosecond Lasers: AOPicoTM Series offers cutting-edge picosecond laser technology for industrial applications.

- Advanced Diode-Pumped Solid-State Laser Solutions: Utilizing OptowaveTM technology for enhanced performance and reliability.

- Versatile Wavelength Options: Available in IR (1064 nm), Green (532 nm), and UV (355 nm) for diverse applications.

- High Average Power: Delivers up to 45W of average power for demanding tasks.

- Precision Pulse Durations: Achieves pulse durations of 7 ps for high-precision micro-machining.

- Excellent Beam Quality: Beam quality of M2 < 1.3 ensures superior performance.

- Cost-Effective: Offers the lowest cost of ownership in the industry.

- Highly Reliable Design: Engineered for durability and consistent performance.

- Burst Mode Option: Enhances functionality for specific applications.

- Wide Range of Applications: Ideal for thin-film ablation, medical device manufacturing, polymer processing/machining, semiconductor/PV processing, wafer scribing, and brittle material cutting, drilling, dicing, & sub-surface marking.

- Compliance and Certification: Meets CDRH, ROHS, and CE standards.

- Comprehensive Warranty: Limited warranty available for all Femtosecond IR/GR laser systems.

- Compact and Efficient Design: Laser head dimensions are 25 x 15 x 7 in. (585 x 381 x 179 mm) with a weight of 70 lbs (32 kg).

- Easy Integration and Control: Features RS-232 communication and water cooling for seamless operation.

- Stable Performance: Maintains pulse-to-pulse stability of <2% RMS and average power stability of <3% over 12 hours.

Applications

- Thin-Film Ablation

- Medical Device Manufacturing

- Polymer Processing/Machining

- Semiconductor/PV Processing/Wafer Scribing

- High-Precision, High-Speed Micro-machining

- Brittle Material Cutting, Drilling, Dicing & Sub-Surface Marking

Frequently Asked Questions

What are the applications of the AOPico 355 3-100?

What is the warranty coverage for the AOPico 355 3-100?

What is the AOPico 355 3-100?

What is the average power of the AOPico 355 3-100?

What is the pulse duration of the AOPico 355 3-100?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle