Description

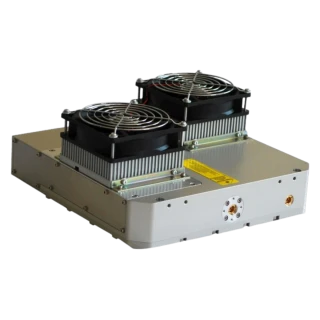

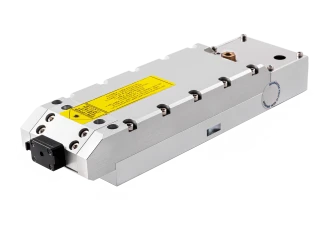

The AWAVE SERIES by Advanced Optowave represents a pinnacle of innovation in industrial laser technology. Designed to meet the rigorous demands of continuous 24/7 production environments, these lasers utilize cutting-edge Q-switched TEM00 mode technology. Each system is meticulously engineered, comprising a laser head and a laser controller, interconnected by a 2.5-meter umbilical cable. The fiber-coupled pumping diodes are conveniently housed within the laser controller, allowing for easy field replacement and ensuring minimal downtime.

One of the standout features of the AWAVE GR Series is its ability to maintain exceptional beam quality, pulse stability, and point stability. This is achieved through the use of patent-pending harmonic conversion technologies and brand-new focusing optics, all housed within an ultra-compact and lightweight design. The laser head is sealed in a clean room environment, which significantly enhances its long-term reliability and operational efficiency.

With a focus on flexibility, the AWAVE GR Series lasers offer pulse frequencies ranging from 1-300 kHz, with optional extension up to 1 MHz. They deliver average power outputs from 10mW to 30W, with pulse energy exceeding 10mJ. For applications requiring more than 30W, the AW-HP Series is recommended. These lasers are engineered with adaptable architectures to meet a wide array of industrial needs. Advanced Optowave is committed to continuous product improvement, ensuring that the AWAVE SERIES remains at the forefront of industrial laser technology.

AONano 532-15W-50K ND:YV04 GR Laser

Specifications

| Avg. Power: | 15 W |

|---|---|

| Wavelength: | 532 nm |

| Repetition Rate: | 1 – 300 kHz |

| Spatial Mode (M^2): | 1.2 |

| Pulse Duration: | 10 ns |

| Pulse-to-Pulse Stability (RMS): | 2 % |

| Cooling: | Air |

| Spatial Mode: | TEM00 |

| Beam Roundness: | >90% |

| Pulse Energy (mJ @ 1kHz): | >300uJ |

| Polarization Ratio: | >100:1 LINEAR, VERTICAL |

| Communication Protocol: | RS-232 |

| Operating Voltage (VAC): | 90-260 |

| Line Frequency (Hz): | 47-63 |

| Operation Temperature: | 15º - 30º C |

| Storage Temperature: | -20º - 50º C |

Features

- Innovative End-Pumping Technology: Experience superior laser performance with advanced end-pumping technology.

- Air-Cooling System: Efficient air-cooling supports average power up to 10W, ensuring optimal operation.

- Excellent Beam Quality: Achieve outstanding beam quality, pulse stability, and point stability for precise applications.

- Patent Pending Harmonic Conversion Technologies: Utilize cutting-edge harmonic conversion for enhanced laser capabilities.

- Ultra-Compact & Light-Weight Design: Benefit from a space-saving and portable laser solution.

- Brand-New Focusing Optics: Advanced optics provide improved focusing for high precision tasks.

- Field-Replaceable Diode: Simplified maintenance with easily replaceable diodes located in the laser controller.

- 24/7 Proven Reliability: Engineered for continuous operation in demanding production environments.

- Low Operational Cost: Cost-effective operation with reduced maintenance needs.

- Q-Switched TEM00 Mode Lasers: Designed for high-demand environments, featuring pulse frequencies from 1-300 kHz.

- Flexible Laser Architectures: Customizable designs to meet unique laser requirements beyond standard specifications.

- Comprehensive Warranty: Limited warranty coverage for all AWAVE Series laser systems.

Applications

- Micromachining: Precision cutting, drilling, and structuring of delicate materials.

- Semiconductor Manufacturing: High-stability laser processing for wafer scribing and trimming.

- Medical Device Fabrication: Fine processing of metals and polymers used in medical tools.

- Electronics & Display: Marking, patterning, and structuring of microelectronic components.

- Scientific Research: Suitable for applications requiring high-quality, stable laser sources.

Frequently Asked Questions

What is the AWAVE GR Series laser used for?

What is the pulse frequency range of the AWAVE GR Series laser?

What is the average power range of the AWAVE GR Series laser?

What is the pulse energy of the AWAVE GR Series laser?

What is the warranty period for the AWAVE GR Series laser?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle