Description

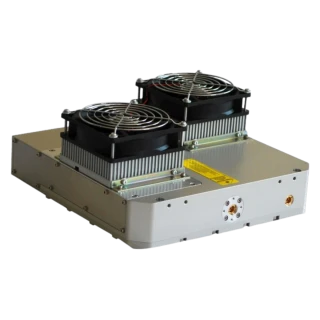

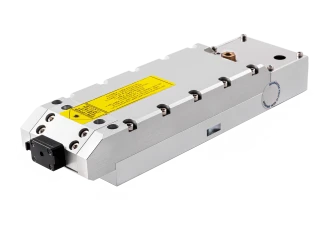

Introducing the AWAVE UV Series, a revolutionary line of Q-switched TEM00 mode lasers meticulously crafted for the rigorous demands of a 24/7 production environment. These industrial lasers are engineered with precision to deliver outstanding performance and reliability, making them an ideal choice for various applications requiring high-quality laser solutions. The AWAVE UV Series stands out with its innovative end-pumping technology and air-cooling system, ensuring average power outputs of up to 6W while maintaining excellent beam quality, pulse stability, and point stability.

The AWAVE UV Series is designed with a unique architecture that includes a laser head and a laser controller, connected via a 2.5-meter umbilical cable. This design facilitates easy field-replacement of fiber-coupled pumping diodes, which are conveniently housed within the laser controller. The laser head is meticulously sealed in a clean room environment, guaranteeing long-term reliability and consistency in performance. With pulse frequencies ranging from 1-300 kHz (and up to 500 kHz as an option), the AWAVE UV Series accommodates a wide range of power requirements, from 100mW to 15W, with pulse energy exceeding 4mJ.

Each laser in the AWAVE UV Series is equipped with patent-pending harmonic conversion technologies and brand-new focusing optics, ensuring ultra-compact and lightweight designs. The series is renowned for its 24/7 proven reliability and low operational cost, making it a cost-effective choice for businesses seeking high-performance laser solutions. Advanced Optowave Corporation remains committed to continuous product improvement, ensuring that the AWAVE Series consistently meets and exceeds industry standards.

AONano 355-2W-6K ND:YAG UV Laser

Specifications

| Avg. Power: | 2 W |

|---|---|

| Wavelength: | 355 nm |

| Repetition Rate: | 1 – 20 kHz |

| Spatial Mode (M^2): | 1.2 |

| Pulse Duration: | 30 ns |

| Pulse-to-Pulse Stability (RMS): | 2 % |

| Cooling: | Air |

| Spatial Mode: | TEM00 |

| Beam Roundness: | >90% |

| Pulse Width (ns): | <40ns @1kHz |

| Pulse Energy (mJ @ 1kHz): | >0.8mJ |

Features

- Innovative End-Pumping Technology: Provides efficient and reliable laser operation.

- Air-Cooling with Average Power Up to 6W: Ensures optimal performance without the need for complex cooling systems.

- Excellent Beam Quality, Pulse Stability & Point Stability: Delivers high precision and consistent results.

- Patent Pending Harmonic Conversion Technologies: Enhances laser functionality and versatility.

- Ultra-Compact & Light-Weight Design: Facilitates easy integration into various systems and applications.

- Brand-New Focusing Optics: Offers superior focus and accuracy for demanding tasks.

- Field-Replaceable Diode: Simplifies maintenance and reduces downtime.

- 24/7 Proven Reliability: Engineered for continuous operation in rigorous production environments.

- Low Operational Cost: Economical to operate and maintain, providing excellent value.

Applications

- Micromachining: Ideal for precision cutting and drilling of small components in industries such as electronics and medical devices.

- Semiconductor Manufacturing: Used in the production of semiconductor components, ensuring high precision and quality.

- PCB Processing: Efficient for cutting and structuring printed circuit boards with minimal thermal impact.

- Marking and Engraving: Provides high-speed marking and engraving on various materials with excellent resolution.

- Thin Film Patterning: Suitable for patterning thin films used in displays and photovoltaic cells.

- Glass and Ceramic Processing: Capable of cutting and engraving glass and ceramic materials with high precision.

- Medical Device Manufacturing: Used in the production and processing of medical devices, ensuring precision and reliability.

- Research and Development: Supports various R&D applications requiring precise laser processing capabilities.

- 3D Printing and Additive Manufacturing: Enhances the precision and quality of 3D printed components.

Frequently Asked Questions

What is the AWAVE UV Series laser used for?

What are the features of the AWAVE UV Series laser?

What is the pulse frequency range of the AWAVE UV Series laser?

What is the average power range of the AWAVE UV Series laser?

What is the pulse energy range of the AWAVE UV Series laser?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle