Description

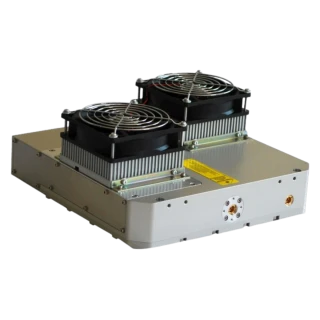

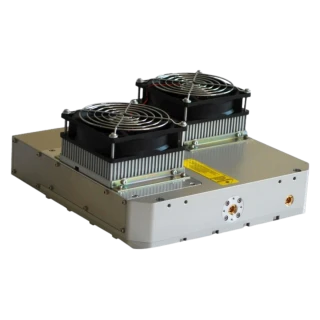

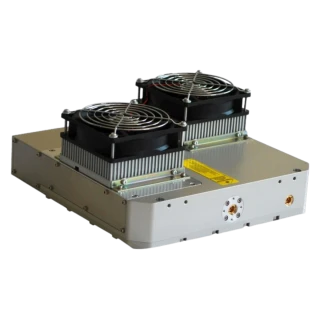

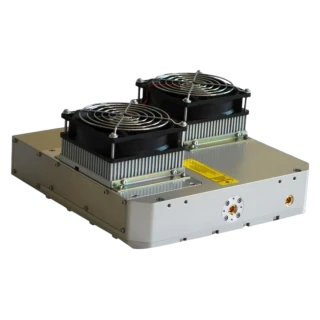

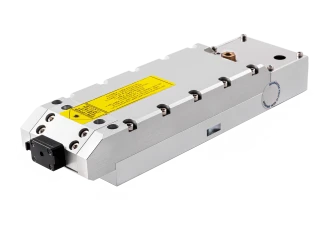

The HP102 UV DPSS Laser from Suzhou Delphi Laser Co., Ltd. is a cutting-edge laser system designed to meet the demands of high-precision applications. With its advanced resonant cavity design, this laser delivers exceptional beam quality and narrow pulse widths even at high power settings. This makes it an ideal choice for industries requiring precision and reliability.

One of the standout features of the HP102 is its ability to maintain stable and efficient harmonic conversion, thanks to its special thermal compensation and frequency conversion technologies. This ensures consistent performance over extended periods, making it a reliable tool for continuous operations. The laser is engineered to provide long-run working stability, which is crucial for maintaining productivity and reducing downtime.

In addition to its technical capabilities, the HP102 boasts a small size and compact design, allowing for easy integration into various setups without occupying excessive space. The laser is assembled in a class 1000 cleanroom environment, ensuring the highest standards of cleanliness and precision during manufacturing. This meticulous attention to detail in its construction further enhances its performance and longevity.

10W UV DPSS Laser Source

Specifications

| Avg. Power: | 10 W |

|---|---|

| Wavelength: | 355 nm |

| Repetition Rate: | 40 – 100 kHz |

| Spatial Mode (M^2): | 1.3 |

| Pulse Duration: | 20 ns |

| Pulse-to-Pulse Stability (RMS): | 2 % |

| Cooling: | Water-to-Water |

Features

- High UV Output Power: Provides 10W average power at 40kHz for demanding applications.

- Ultra-Short Pulse Width: Delivers <20ns pulses for high-precision micromachining.

- Adjustable Repetition Rate: Operates from 40 to 100kHz (up to 150kHz burst mode) for process flexibility.

- Excellent Beam Quality: Maintains TEM00 spatial mode with M² <1.3 for clean processing.

- Thermal Compensation Technology: Ensures efficient and stable harmonic conversion.

- Comprehensive Control Options: RS232, GATE, TRIGGER, and PWM signals enable precise integration.

- Compact and Robust Design: Facilitates easy system integration and installation.

- High Long-Term Stability: Provides <±3% power stability over 8 hours for reliable operation.

Applications

- Glass Cutting: Enables precise, high-speed UV cutting of glass substrates.

- Laser Marking: Produces fine, durable markings on metals, plastics, and ceramics.

- Material Micromachining: Supports intricate structuring of diverse materials with minimal heat effects.

- Wafer Cutting: Ideal for dicing and scribing semiconductor wafers with high edge quality.

- Micro-Drilling: Achieves micro-hole drilling in polymers, ceramics, and thin metals.

- Laser Rapid Prototyping: Enhances additive manufacturing with UV-based fine detailing.

- Scientific Research: Suitable for photonics experiments and material analysis requiring UV lasers.

Frequently Asked Questions

What are the applications of the HP series UV DPSS lasers?

What is the warm-up time for the HP102 UV DPSS Laser?

What is the cooling method used for the HP102 UV DPSS Laser?

What is the gain medium of the Delphi ultraviolet series lasers?

What is the average power of the HP102 UV DPSS Laser?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle