Description

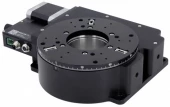

The X-RST-DE Series from Zaber represents a pinnacle in high precision motorized rotary stages, meticulously designed to simplify motion control tasks. With built-in controllers and direct encoders, these devices offer unmatched accuracy and reliability, ensuring that every rotation is precise to 0.01 degrees. The 50.8 mm (2 inch) aperture, complemented by kinematic mounting options, guarantees repeatability in assembly, making it an indispensable tool for applications demanding high precision and consistency.

Engineered to handle substantial loads, the X-RST-DE Series boasts a centered load capacity of 50 kg, paired with a torque capability of up to 10 N-m. This makes it exceptionally suited for high load and angular positioning applications. Despite their robust capabilities, these stages are stand-alone units, requiring only a standard 24-48 V power supply, which simplifies integration into existing systems. The intuitive indexed knob allows for smooth manual control, offering variable speeds in both directions and enabling versatile operation even in the absence of a computer.

Connectivity and integration are seamless with the X-RST-DE Series. The stages can be connected to a computer via USB 2.0 or RS-232 ports and can be daisy-chained with multiple units, including other Zaber products. This feature not only simplifies the setup but also optimizes power consumption, as multiple X-Series products can share a single power supply. The secure, locking 4-pin M8 connectors ensure that connections are both easy and reliable, providing peace of mind during operations.

X-RST-DE: Precision Motorized Rotary Stage with Built-in Controller

Specifications

| Vacuum Compatible: | No |

|---|---|

| Built-in Controller: | Yes, Optional |

| Range: | 360 degrees |

| Unidirectional Accuracy: | 0.01 degrees |

| Repeatability: | <0.005 degrees |

| Backlash: | 0.005 degrees |

| Encoder Resolution: | 16200 CPR |

| Stage Diameter: | 120 mm |

| Direct Reading Encoder: | Yes |

| Built-in Controller: | Yes |

| Calibration Report Available: | Yes |

| Aperture With Kinematic Mounting Options: | 50.8 mm |

| Centred Load Capacity: | 50 kg |

| Maximum Speed: | 24 degrees/s |

| Maximum Torque: | 10 N-m |

Features

- High Precision Motion: Equipped with a direct reading encoder for precise position correction, ensuring stage accuracy of up to 0.01 degrees.

- Large Aperture: Features a 50.8 mm (2 inch) aperture with kinematic mounting options for repeatability of assembly.

- Robust Load Capacity: Capable of supporting a centered load capacity of up to 50 kg.

- Fast and Powerful: Achieves speeds up to 24 degrees per second and torque up to 10 N-m.

- Built-in Controller: Includes an integrated controller that simplifies setup and operation, with daisy-chain capability for multiple Zaber products.

- Single Power Supply: Multiple X-Series products in a daisy-chain can share a single power supply, enhancing efficiency.

- Versatile Manual Control: Indexed knob allows for smooth manual operation with variable speeds in both directions, even without a computer.

- Easy Connectivity: Connects via USB 2.0 or RS-232 ports and features convenient locking, 4-pin, M8 connectors for secure connections.

- Wide Range of Motion: Offers a full 360-degree range with high accuracy and repeatability.

- Precision Engineering: Designed with a precision worm gear mechanical drive system and a magnetic home sensor for reliable performance.

- Environmentally Compliant: Meets RoHS and CE compliance standards.

- Durable Construction: Built to withstand operating temperatures from 0 to 50 degrees Celsius.

Applications

- Precision Optical Component Alignment: For lenses, mirrors, and beam steering

- Heavy-Duty Automation: Robust rotary positioning in manufacturing and robotics

- Metrology and Testing: High-accuracy angular positioning for measurement systems

- Research & Development: Repeatable, stable positioning for experimental setups

- Semiconductor Equipment: Precise motion control in wafer inspection and processing

Frequently Asked Questions

What is the load capacity of Zaber's X-RST-DE Series motorized rotation stage?

What is the communication interface of Zaber's X-RST-DE Series motorized rotation stage?

What is the torque capacity of Zaber's X-RST-DE Series motorized rotation stage?

What is the maximum speed of Zaber's X-RST-DE Series motorized rotation stage?

What is the accuracy of Zaber's X-RST-DE Series motorized rotation stage?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle