Description

Zaber's X-RSW-SV2 Series represents a breakthrough in high-vacuum compatible, computer-controlled motorized rotary stages. These innovative devices are designed to simplify motion control with their built-in controllers, offering a seamless solution for those requiring precision and reliability in demanding environments. The X-RSW-SV2 Series stands out as a stand-alone unit, needing only a standard 24 - 48 V power supply, which makes it exceptionally easy to integrate into existing systems.

The X-RSW-SV2 Series connects effortlessly to the RS-232 or USB ports of any computer, allowing for straightforward control and operation. Additionally, these stages can be daisy-chained with other Zaber products, enabling a shared power configuration that reduces the need for multiple power supplies. This capability not only simplifies setup but also enhances the flexibility of the system, making it ideal for complex applications where multiple devices are required.

Engineered with vacuum-compatible materials, the X-RSW-SV2 Series minimizes outgassing, which contributes to faster pump-down times and improved performance in vacuum environments. True to Zaber's commitment to user-friendly design, these rotary stages are 'plug and play', ensuring that users can quickly and easily set up and operate the system without extensive technical knowledge.

Overall, the X-RSW-SV2 Series is an exemplary choice for those seeking a high-performance, reliable, and easy-to-use motorized rotary stage for high-vacuum applications. Its robust construction and thoughtful design make it a valuable asset in any precision motion control setup.

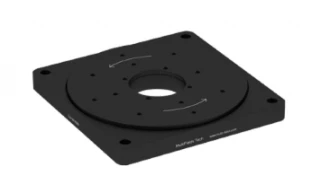

High Vacuum Motorized Rotary Stage X-RSW60A-SV2

Specifications

| Vacuum Compatible: | Yes |

|---|---|

| Built-in Controller: | Yes |

| Range: | 360 degrees |

| Unidirectional Accuracy: | 0.14 degrees |

| Repeatability: | <0.05 degrees |

| Backlash: | 0.04 degrees |

| Stage Diameter: | 60 mm |

Features

- Vacuum Compatibility: Designed for high-vacuum environments, compatible to 10-6 Torr.

- Continuous Rotation: Worm gear driven for seamless and continuous rotation.

- Load Capacity: Supports up to 20 kg, ensuring robust performance for various applications.

- Performance: Achieves speeds up to 100 °/s and torque up to 100 N·cm.

- Integrated Control: Features a built-in stepper motor controller and motor driver for easy operation.

- Simplified Connectivity: Requires only 4 feedthrough wires for daisy-chain control via serial port with an X-PIB adaptor.

- Compatibility: Connects to RS-232 or USB ports and can be daisy-chained with other Zaber products.

- Construction: Made with vacuum-compatible materials to minimize outgassing and expedite pump down times.

- Plug and Play: Designed for easy setup and operation, ensuring quick integration into your system.

- Precision and Accuracy: Offers a microstep size of 0.000234375° and an accuracy of 0.14°.

- Repeatability: Ensures repeatability of less than 0.02° for consistent performance.

- Communication Interface: Utilizes RS-232 with Zaber ASCII and Zaber Binary protocols.

- Power Requirements: Operates on a 24-48 VDC power supply, with a maximum current draw of 950 mA.

- Mechanical System: Equipped with a precision worm gear drive and magnetic home sensor for reliable motion control.

- Environmental Compliance: RoHS and CE compliant, suitable for a wide range of environments.

Applications

- Beamline Instrumentation: Precise rotation of samples or optics within beamline vacuum chambers.

- Vacuum Chamber Automation: Enables accurate rotational positioning in high vacuum environments.

- Optical Component Alignment: Ideal for angular alignment of mirrors, gratings, and polarizers.

- Semiconductor Processing: Supports wafer rotation and inspection under vacuum conditions.

- Research Laboratories: Suitable for automated multi-axis experimental setups requiring rotation.

Frequently Asked Questions

What is the load capacity of the X-RSW-SV2 Series rotary stage?

What is the maximum speed of the X-RSW-SV2 Series rotary stage?

What is the communication interface of the X-RSW-SV2 Series rotary stage?

Can the X-RSW-SV2 Series rotary stage be daisy-chained with other Zaber products?

What is the accuracy of the X-RSW-SV2 Series rotary stage?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle