Description

Simplifying Motion Control with the X-LSM Series

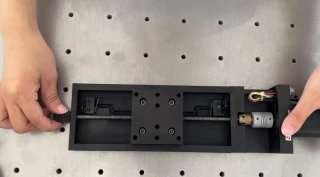

The X-LSM Series represents a new era in miniature motorized linear stages, offering built-in controllers for seamless operation. Designed by Zaber, these devices are computer-controlled, providing high thrust and speed capabilities within a compact form factor. The X-LSM Series is a stand-alone unit, requiring only a standard 24 V or 48 V power supply, which simplifies setup and integration into any system. An optional indexed knob adds the flexibility of manual control, making it versatile for various operational needs without relying solely on computer interfaces.

Connectivity is a key feature of the X-LSM Series. These stages can easily connect to a computer via RS-232 or USB ports, and they support daisy-chaining with other Zaber products. This daisy-chain capability not only simplifies the wiring but also allows multiple X-Series products to share a single power supply, enhancing efficiency. The secure locking 4-pin M8 connectors ensure reliable connections between units, further streamlining the setup process.

With a height of just 21 mm, the X-LSM Series is ideal for applications requiring a small profile. Despite its compact size, the innovative design of the X-LSM allows it to achieve speeds of up to 104 mm/s while handling loads of up to 10 kg. As with all Zaber products, the X-LSM Series is designed for 'plug and play' simplicity, ensuring ease of setup and operation. For multi-axis systems, these stages are particularly well-suited for use as microscope stages in XY configurations. The addition of a X-JOY3 joystick controller facilitates manual control over X, Y, or XYZ axes, allowing for precise and repeatable positioning at the touch of a button.

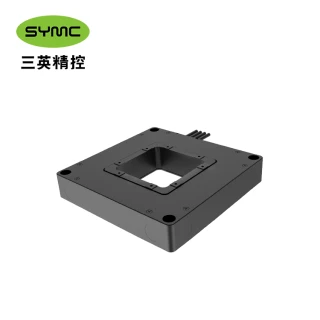

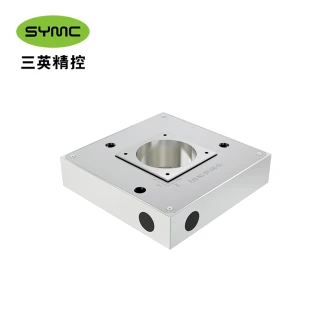

X-LSM Series Miniature Motorized Linear Stages with Controller

Specifications

| Axes Of Motion: | Two, Three, One |

|---|---|

| Travel Range: | 200 mm |

| Load Capacity (Horizontal): | 10 kg |

| Load Capacity (Vertical): | 10 kg |

| Max Speed: | 104 mm/s |

| Built-in Controller: | Yes |

| Maximum Centred Load: | 100 N |

| Microstep Size: | 0.047625, 0.1905 µm |

Features

- Travel Range Options: Available in 25, 50, 100, 150, and 200 mm travel ranges to suit various applications.

- High Load Capacity: Capable of handling loads up to 10 kg, ensuring robust performance.

- Exceptional Speed and Thrust: Achieves speeds up to 104 mm/s and thrust up to 55 N for efficient operation.

- Integrated Controller: Built-in controller allows for seamless integration and operation without additional hardware.

- Compact Design: With a height of only 21 mm, these stages are ideal for applications where space is limited.

- Plug and Play: Easy setup and operation, designed to work out of the box with minimal configuration.

- Flexible Connectivity: Connects via RS-232 or USB ports and can be daisy-chained with other Zaber products, sharing power and communication.

- Manual Control Option: Optional indexed knob for convenient manual operation without a computer.

- Secure Connections: Features locking 4-pin M8 connectors for reliable and secure connections.

- Versatile Mounting: M3 and M6 threaded holes, along with an M4 threaded center hole, provide flexible mounting options.

- Precision Motion: Equipped with a precision lead screw drive system and magnetic hall sensor for limit or home sensing.

- Compliance and Safety: RoHS and CE compliant, ensuring adherence to safety and environmental standards.

- Multi-Axis Capability: Ideal for multi-axis systems, particularly in XY configurations for microscope stages.

- Additional Control Options: Compatible with X-JOY3 joystick controller for intuitive manual control and position memory.

Applications

- Microscope Stages: The X-LSM Series is ideal for use in microscope applications, particularly in multi-axis systems configured in XY. The compact design and high precision make it perfect for precise positioning in microscopy.

- Automated Testing: With its high speed and load capacity, the X-LSM Series can be used in automated testing environments where precise and repeatable motion control is required.

- Optical Alignment: The precision and stability of the X-LSM Series make it suitable for optical alignment tasks where small adjustments are necessary.

- Assembly Automation: Its ability to handle loads up to 10 kg and speeds up to 104 mm/s makes it suitable for use in automated assembly lines where components need to be moved quickly and accurately.

- Research and Development: The versatility and ease of integration with other Zaber products make the X-LSM Series a great choice for R&D environments where flexibility and precision are paramount.

- Semiconductor Manufacturing: The compact size and high precision of the X-LSM Series can be advantageous in semiconductor manufacturing processes that require precise motion control.

- Medical Device Manufacturing: The precision and reliability of these stages make them suitable for use in the manufacturing of medical devices where accuracy is critical.

- Material Testing: The high thrust and speed capabilities of the X-LSM Series allow for efficient and accurate material testing applications.

Frequently Asked Questions

Can multiple X-Series products share a single power supply?

Can the X-LSM Series be controlled manually?

What type of power supply is required for the X-LSM Series?

What is the speed capability of the X-LSM Series?

What is the load capacity of the X-LSM Series?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle