Description

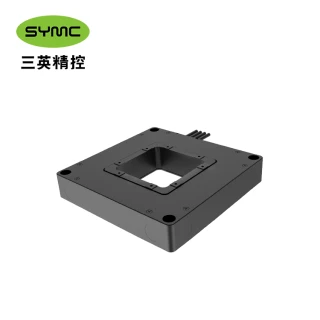

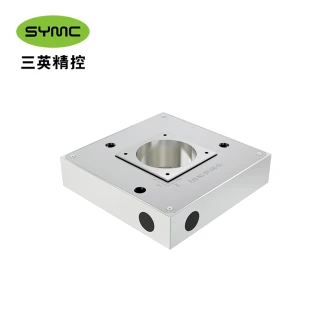

CXP series linear stages are high-precision motorized linear stages designed and manufactured by Zolix, especially for the use cases where small-size and high frequency of operation are of high importance.

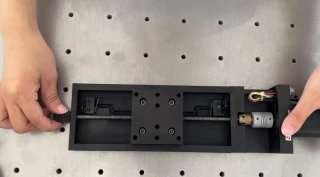

Hard Aluminum Body: This family of products is made of hard aluminum alloy with black anodic-oxidation surface treatments that ensure good wear resistance and nice appearance. A set of cross-roller guide is employed which offers high motion precision even with heavy load.

Imported High End Ball Screws: The High-Precision Motorized Linear Stage uses imported ball screws (1mm lead pitch), which are the key parts of driving mechanism and used with two-phase stepping motors (Japanese brands) to ensure accurate micro-step capabilities and high positioning accuracy.

Integration Ready: These linear motorized stages are ideal for integration into customer's own systems such as automation equipment, instruments and production lines in which limited space must be considered.

CXPF series is one of the derivative version of CXP family. A new type of ball screw which has a longer lead pitch (2mm) and a set of new cross-roller guides used to replace the original ones to meet the requirements of rapid movement, high rigidity, and long travel range.

High-Precision Motorized Linear Stage: CXP and CXPF Series

Specifications

| Axes Of Motion: | One |

|---|---|

| Travel Range: | 15 mm |

| Load Capacity (Horizontal): | 5 kg |

| Load Capacity (Vertical): | 3 kg |

| Max Speed: | 20 mm/s |

| Weight: | 1.2 kg |

| Guiding Mechanism: | Crossed Roller Slides |

| Voltage Requirement: | DC 24V, DC 36V |

| Repositioning Accuracy With Microstep Motion: | ≤±1 µm |

| Backlash Clearance With Microstep Motion: | ≤0.5 µm |

| Brand And Model Number Of Stepping Driver (optional): | Moons, SR2 |

| Type Of Plugs For Stages: | 1*DB9 (pin) |

| Type Of Cables For Stages: | High flexible cables (Helukabel, Germany) |

| Length Of Cables For Stages: | 0.2 m |

| Voltage Of Power Supply For Sensors: | DC5~24V ±10% |

Features

- Using short-lead-pitch ball screws with two-phase stepping motors to provide good micro-step capability and rigidity;

- Cross-roller guides ensure better rigidity and higher load capability;

- Installation surface treated by using fine grinding techniques to guarantee higher motion precision

- Three built-in sensors (positive- and negative position limit sensors and one origin-point sensor) were installed with flexible cables and relative units to make sure easy maintenance.

Applications

- Optical Alignment

- Spectroscopic Measurements

- Optical Prototyping

Frequently Asked Questions

What is the main body materials for this High-Precision Motorized Linear Stage?

What linear travel ranges do you have for this motorized linear stage?

What is the maximum load I can place on the motorized linear stage without affecting the precision?

What is the voltage requirement for the linear motorized stage?

What are the key features of the High-Precision Motorized Linear Stage?

What are the dimensions and travel ranges of the available models?

- CXP15-40: Table Dimension 40x40 mm, Travel Range 15 mm

- CXPF30-80: Table Dimension 80x80 mm, Travel Range 30 mm

- CXPF75-80125: Table Dimension 80x125 mm, Travel Range 75 mm

What are the applications suitable for the High-Precision Motorized Linear Stage?

Can the High-Precision Motorized Linear Stage be integrated into customer's own systems?

What are the differences between the CXP and CXPF series?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle