Description

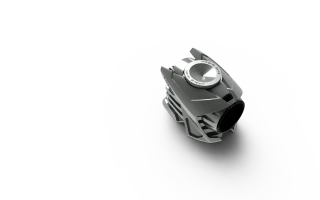

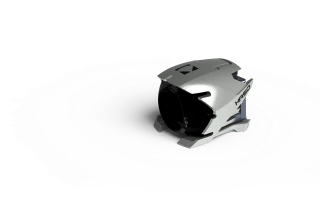

A great choice for the most demanding SWIR optical metrology applications, the LIFT SWIR 160 wavefront sensor provides the highest resolution in SWIR, and advanced features such SpotTracker for alignment. It also instantly combines with any other compatible instrument and accessory in the Optical Engineer Companion range.

The advantages of wavefront sensing-based metrology in the Short – wave infrared first stem from Shack-Hartmann’s reliability and accuracy as well as its 25-year track record with the most popular, creative and demanding clients, including space agencies, semiconductor businesses, laser manufacturers , free-space communications companies, and AR/VR designers and manufacturers.

LIFT SWIR 160 Wavefront Sensor

Specifications

| Wavelength Range: | 980 – 1650 nm |

|---|---|

| # Pixels (Width): | Not Specified |

| # Pixels (Height): | Not Specified |

| Lenslet Pitch: | Not Specified |

| Wavefront Accuracy: | Other |

| Type: | Shack Hartmann, Hartmann, Zernike, Other / Not specified |

| Repeatability:: | < lambda/200 RMS |

| Phase Point Resolution:: | 640 x 512 |

| Pupil Size:: | 9,30 x 7,44 mm² |

| Absolute Accuracy: | λ/100 RMS |

| Phase Sampling: | 160 x 128 |

Features

Successfully used in the most demanding applications in optical metrology, laser diagnostics and adaptive optics, the LIFT SWIR 160 performs multiple functions:

- Direct wavefront acquisition of highly converging and diverging beams with an accuracy of λ/100 rms, including astigmatism and high-order aberration, and many other parameters, making for the perfect instrument for any complex optics alignment.

- Beam collimation with sensitivity > 1 km radius of curvature

- Control and adjustment of axial laser beam deviation > 3μrad rms

- Complex optics characterization in single or double path configuration in combination with R-FLEX2 metrology systems or RFLEX LA metrology platforms.

- 3D MTF measurements

- Simultaneous and independent measurements of phase and intensity (patented)

Applications

- Optical manufacturing metrology

- Complex optics Characterization

- Middle frequencies mirror surface characterization

- Optical quality control, metrology (LIDAR, free space communication, Automotive, Space and defense)

- Prediction of an optical system performance in terms of focalization capability or imaging quality

- Pilot a wavefront corrector to control system’s aberrations

- Quantification of the effects of temperature and gravity on the performance of an optical system

Frequently Asked Questions

What is the resolution of the LIFT SWIR 160 wavefront sensor?

What is the accuracy of the wavefront acquisition?

Can the LIFT SWIR 160 perform beam collimation?

What are the applications of the LIFT SWIR 160?

Does the LIFT SWIR 160 have the ability to correct system aberrations?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle