Description

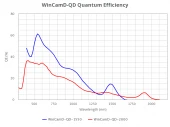

The WinCamD-QD laser beam profiler series uses colloidal quantum dot sensors to provide high quality beam profiling for visible, SWIR, and eSWIR sources. With 15 µm pixels, a wavelength range as wide as 350-2000 nm, and a global shutter, the WinCamD-QD series offers unparalleled laser beam profiling capabilities.

With a signal-to-noise ratio that exceeds 2100:1, the WinCamD-QD series is capable of ISO 11146 compliant beam measurements. The state-of-the-art colloidal quantum dot sensor features very high sensitivity with a global shutter for pulsed beam profiling.

The WinCamD-QD series is supported by DataRay’s full-featured, highly customizable, user-centric software which has no license fees, unlimited installations, and free software updates.

The DataRay software allows you to interface with external programs, log data, conduct fully automated M2 measurements using our M2DU translation stages, and much more, all included without any additional charges. For higher power lasers, DataRay offers a range of sampling, absorbing, and reflecting attenuation options to assure your beam is adequately attenuated before profiling.

WinCamD-QD – Quantum Dot SWIR Beam Profiler

Specifications

| Sensor Type: | Colloidal Quantum Dot (CQD) |

|---|---|

| Measurable Sources: | CW |

| Wavelength Range: | 400 – 1700 nm |

| # Pixels (Width): | 1920 |

| # Pixels (Height): | 1080 |

| Pixel Size (Width): | 15 um |

| Pixel Size (Height): | 15 um |

| Max Full Frame Rate: | 25 Hz |

| ADC: | 14-bit |

| Optical Depth From Housing/filter To Sensor ±0.2 Mm: | approximately ~7.6/12mm |

| Certification: | RoHS, WEEE, CE |

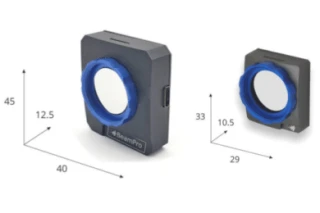

| Camera Dimensions (W X H X D): | 61 x 61 x 99 mm |

| Measurable Sources: | CW beams, pulsed sources with external synch |

| Opt./Elec.: | 33/66 dB |

| Signal To RMS Noise: | ≥2100:1 |

| Shutter Type: | Global |

| Min. Beam (10 Pixels): | ~150 µm |

| Pixel Count, H X V: | S-WCD-QD-1550/2000: 640x512; S-WCD-QD-1550/2000-L: 1280x1024: S-WCD-QD-1550/2000-XL: 1920x1080 |

| Other Wavelength Option (S-WCD-QD-2000 Series: VIS-eSWIR): | SWIR (400-1,700nm) or eSWIR (350-2,000nm) |

Features

- Quantum dot sensor, optimized for 1550 or 2000 nm

- Covers wavelengths 400 to 1700 nm or 350 to 2000 nm

- Multiple active area options, to 1920 x 1080

- 15 µm pixels

- 14-bit ADC

- Global shutter; supports pulsed and CW beams

- >2100:1 dynamic range

- In-firmware NUC

- Parallel capture on multiple cameras

- M² measurements

- GigE or USB 3.0 with 3 m screw locking cable

- GigE Vision/USB3 Vision support

Applications

- 1550 nm / 2000 nm laser beam profiling

- Profiling 1550 nm laser sources used in fiber-optic communications, ensuring optimal beam quality and alignment

- Field servicing of 1550 nm / 2000 nm lasers and laser-based systems

- Useful in calibrating and maintaining laser systems in medical devices, particularly those operating in the SWIR range

- Applicable in profiling laser syst

- Assists in the development and maintenance of laser-based environmental sensing equipment operating in the SWIR spectrum

- Optical assembly & instrument alignment

- Beam wander & logging

- Enables monitoring and control of laser beams in industrial processes like welding, cutting, and material processing

- M² measurement with available M2DU stage

Frequently Asked Questions

What is the wavelength range of the WinCamD-QD series?

The WinCamD-QD series has a wavelength range of 350-2000 nm.

What is the signal-to-noise ratio of the WinCamD-QD series?

The WinCamD-QD series has a signal-to-noise ratio that exceeds 2100:1.

Can the WinCamD-QD series be used for pulsed beam profiling?

Yes, the WinCamD-QD series features a global shutter for pulsed beam profiling.

What software is included with the WinCamD-QD series?

The WinCamD-QD series is supported by DataRay's full-featured, highly customizable, user-centric software, which has no license fees, unlimited installations, and free software updates.

Does the WinCamD-QD series offer options for attenuating higher power lasers?

Yes, DataRay offers a range of sampling, absorbing, and reflecting attenuation options to ensure the beam is adequately attenuated before profiling.

What is the minimum beam size that the WinCamD-QD can accurately profile?

This laser beam profiler can accurately measure beam diameters as small as approximately 150 µm, depending on the specific model and configuration.

Can the WinCamD-QD perform M² measurements?

Yes, when used with DataRay’s M²DU translation stages, the profiler can perform ISO 11146 compliant M² measurements.

What are the available interface options for the WinCamD-QD?

It offers both USB 3.0 and GigE Vision interfaces, providing flexibility in connectivity and data transfer speeds.

Is the WinCamD-QD compatible with third-party software?

The profiler is compatible with DataRay's proprietary software, which includes features for data export that can be used with third-party analysis tools.

Similar Products

BeamPro | Compact Footprint Laser Beam Profiler

Axiom Optics

BeamPro | Large Area Laser Beam Profiler

Axiom Optics

BeamPro | Small Pixel Laser Beam Profiler

Axiom Optics

Wavefront Sensor Based Laser Beam Profiler - SID4

PHASICS

CaM² M-Squared meter

Imagine Optic

CMOS Beam Profiler

YIXIST YIXI Technology Co., Ltd

Industrial Laser Monitoring System (ILMS)

DataRay Inc.

BladeCam2-XHR – ½" CMOS Beam Profiler System

DataRay Inc.

BladeCam2-HR – ½" CMOS Beam Profiler System

DataRay Inc.

WinCamD-GCM 1" - GigE Vision CMOS Beam Profiling Camera

DataRay Inc.

ModuOptik - Beam Profiler (CMOS)

Hefei ModuOptik Technologies Co., Ltd.

LOD Beam Image Profiler

Logan Optical Designs (LOD)

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle