Description

The ILMS is specially designed for profiling focused, high-power industrial lasers. This system combines reimaging/magnification optics, a polarization preserving beam sampler, and a DataRay beam profiler to measure small beam waists which would otherwise damage a traditional profiling system. Magnification of the focused beam allows full pixel-by-pixel 2D measurements of beam spots as small as a few microns.

The ILMS is compatible with most DataRay profilers and supported by the full-featured, highly customizable, and user-centric software (included without licensing fees). The software automatically accounts for the magnification of the system, so results do not require post processing or corrections.

Custom solutions available, contact sales@dataray.com or use the "Contact Supplier" button.

Industrial Laser Monitoring System (ILMS)

Specifications

| Sensor Type: | CMOS |

|---|---|

| Measurable Sources: | CW, Pulsed |

| Wavelength Range: | 190 – 16000 nm |

| # Pixels (Width): | 2048 |

| # Pixels (Height): | 2048 |

| Pixel Size (Width): | 5.5 um |

| Pixel Size (Height): | 5.5 um |

| Max Full Frame Rate: | 60 Hz |

| ADC: | 12-bit |

| Magnification: | 1 - 50x+ |

| Minimum PC Requirements: | Windows 7/8/8.1/10/11 64-bit, 4 GB RAM, USB 2.0/3.0 port |

| Weight‚ Camera W/ MagND And Filter Cover: | 5 lbs (2kgs) |

| Mounting: | M6 and M3 mounting points |

| Multiple Cameras: | Up to 4 cameras, parallel capture. 1 to 8 cameras, serial capture. |

| Certification: | RoHS, WEEE, CE |

| Measured & Displayed Profile Parameters: | Raw and smoothed profiles | Triangular running average filter up to 10% FWHM |

| Manual Beam Attenuation: | Includes ND-1, ND-2, and ND-4 filter inserts |

| Displayed Profiles: | Line, 2D & 3D plots. Normalized or un-normalized. Linear or Logarithmic, Zoom x10 2D, 3D in 10, 32 or max. colors or grayscale Contoured display at 10 and 32 colors |

| Measurable Sources: | WinCamD-LCM: CW beams, pulsed sources; CW to 12.6 kHz with single pulse isolation |

| Electronic Shutter Range: | WinCamD-LCM: USB 2.0 @ 12,600:1 (41 dB), USB 3.0 @ 25,000:1 (44 dB) |

| Signal To RMS Noise: | WinCamD-LCM: 2,500:1 (34 dB optical / 68 dB electrical) |

| Single Pulse Capture PRR: | WinCamD-LCM: USB 2.0 @ 6.3 kHz; USB 3.0 @ 12.6 kHz |

| Input Optics NA: | ILMS-5-X: 0.17 | ILMS-10-X: 0.17 | ILMS-50-532-: 0.6 | ILMS-50-1064: 0.65 |

| AR Coating Wavelength: | ILMS-X-UV: 250nm-425nm | ILMS-X-VIS: 425nm-675nm | ILMS-X-532: 532nm | ILMS-X-NIR: 750nm-1550nm | ILMS-X-1064: 1064nm |

| * Effective Pixel Size: | Model specific, down to 5.5um/magnification |

Features

- Options from 190nm up to 16 μm

- Beam waist diameters down to a few μm

- High magnification options available (50X and beyond)

- Capable of measuring high power beams, up to kW range possible

- Three swappable filters for flexible attenuation

- Profiler easily removed from system for stand-alone use

- Optional calibrated pinhole aperture denotes working distance and helps provide protection against damage from beam misalignment

- Available without beam sampler for focused, low power beams

- Integrated power meter options (contact us for more information)

Applications

- Tightly focused beams, fiber ends, edge couplers, laser diodes, and more

- High power laser cutting systems

- Telecommunications

- Quality control

- Laser micro-machining

- Semiconductor wafer inspection

- Additive manufacturing (metal 3D printing)

- Quality assurance in fiber laser systems

Frequently Asked Questions

What is the ILMS used for?

The ILMS is designed for profiling focused, high-power industrial lasers.

What are the features of the ILMS?

The ILMS has options from 190nm up to 16 μm, beam waist diameters down to a few μm, high magnification options available, and it is capable of measuring high power beams. It also has swappable filters, an optional calibrated pinhole aperture, and integrated power meter options.

Does the ILMS require post-processing or corrections for its results?

No, the software included with the ILMS automatically accounts for the magnification of the system, so results do not require post-processing or corrections.

Can the ILMS be used for quality control?

Yes, the ILMS can be used for quality control in applications such as tightly focused beams, fiber ends, edge couplers, laser diodes, and more.

Is the ILMS compatible with most DataRay profilers?

Yes, the ILMS is compatible with most DataRay profilers.

Can this system be integrated with existing laser machines?

Yes, the Industrial Laser Monitoring System is designed for easy integration into a wide range of industrial laser machines, including those used for marking, cutting, and engraving. It offers flexible interfacing options to suit various automation environments.

Is the software compatible with Windows/Mac/Linux?

The included software is primarily compatible with Windows-based systems. For Mac or Linux environments, integration may be possible using custom API or SDK support—please contact the manufacturer for detailed compatibility information.

What beam diameters and wavelengths does it support?

This system supports a broad range of beam diameters and wavelengths, typically from 400 nm to 1100 nm. For exact specifications, refer to the datasheet or contact us with your laser parameters.

Is it suitable for high-power laser systems?

Yes, it is built for industrial environments and can handle moderate to high laser powers. However, the maximum supported power depends on beam size, wavelength, and exposure time—please verify your use case against the technical limits provided.

Similar Products

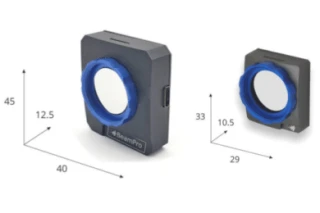

BeamPro | Compact Footprint Laser Beam Profiler

Axiom Optics

BeamPro | Large Area Laser Beam Profiler

Axiom Optics

BeamPro | Small Pixel Laser Beam Profiler

Axiom Optics

Wavefront Sensor Based Laser Beam Profiler - SID4

PHASICS

CaM² M-Squared meter

Imagine Optic

CMOS Beam Profiler

YIXIST YIXI Technology Co., Ltd

BladeCam2-XHR – ½" CMOS Beam Profiler System

DataRay Inc.

BladeCam2-HR – ½" CMOS Beam Profiler System

DataRay Inc.

WinCamD-QD – Quantum Dot SWIR Beam Profiler

DataRay Inc.

WinCamD-GCM 1" - GigE Vision CMOS Beam Profiling Camera

DataRay Inc.

ModuOptik - Beam Profiler (CMOS)

Hefei ModuOptik Technologies Co., Ltd.

LOD Beam Image Profiler

Logan Optical Designs (LOD)

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle