Description

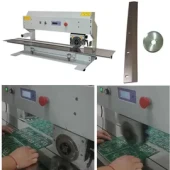

The CWV-1M Manual V-Cut PCB Separator is a precision depaneling machine designed to separate pre-scored PCBs quickly and efficiently without damaging components or stressing the board. With adjustable blade clearance, a durable stainless steel platform, and manual operation via rotary control, it is ideal for small to medium production runs where clean, accurate cuts are essential. This model is available in two variants (460mm and 720mm cut length) to accommodate different panel sizes.

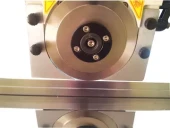

Manual V-Cut PCB Depaneling Machine with Circular and Linear Blades for Stress-Free Separation

东莞市创威智能装备有限公司

Specifications

| Work Area / Panel Length: | 350 mm |

|---|---|

| Work Area / Panel Width: | 350 mm |

| Work Area / Panel Thickness (Max): | 3 mm |

| Scan Field: | Other (see specs) |

| Scan Speed: | Not Specified |

| Laser Output Power: | Not Specified |

| Laser Wavelength: | Not Specified |

| Axis Speed (X): | Not Specified |

| Axis Speed (Y): | Not Specified |

| Axis Speed (Z): | Not Specified |

| Accuracy: | Not Specified |

| Panel Material: | FR4, FPCB, Rigid PCB, Double-Sided PCB |

| Max Cut Length (CWV-1M460): | 460 mm |

| Max Cut Length (CWV-1M720): | 720 mm |

| Speed Control: | Manual (rotary knob) |

| Weight (CWV-1M460): | 30 kg |

| Weight (CWV-1M720): | 45 kg |

Features

- Stress-Free Separation: Separates V-scored PCBs without exerting mechanical stress on components or the board itself.

- Manual Speed Control: Cutting speed is manually controlled via a rotary knob, offering precise control during operation.

- Adjustable Blade Clearance: The distance between the circular (top) and linear (bottom) blades can be adjusted to suit varying groove depths and blade wear.

- One-Touch Cut Length Setting: Digital display allows easy programming of cut length for repeatable performance.

- Stable Cutting Platform: Large stainless steel tables on both sides of the cutting blade reduce board wobble. Table height and angle are fully adjustable.

- Compatible with Complex Boards: Handles intermittent scoring and boards with overhanging components with high precision.

- Compact and Robust Design: Solid build with relatively small footprint; easy to integrate into existing production lines.

Applications

- Depaneling V-scored PCBs in low to medium-volume production

- Separating FR4, FPCB, rigid and double-sided boards

- Ideal for electronics assembly lines requiring precision cutting

- Suitable for cutting boards with delicate or protruding components

- Use in factories manufacturing LED boards, mobile phones, or consumer electronics

Frequently Asked Questions

What types of PCBs can this machine depanel?

It can depanel pre-scored FR4, FPCB, rigid, and double-sided PCBs.

What is the maximum cutting length?

The machine is available in two models: CWV-1M460 (460mm) and CWV-1M720 (720mm) max cutting length.

Similar Products

LED Pcb Depanelizer Tool, CWVC-3 Printed Circuit Board Depaneling Machine

东莞市创威智能装备有限公司

Customized PCB Routing Machine PCB Router,PCB Depaneling Router System,PCB Thickness 0.5-3.5mm

东莞市创威智能装备有限公司

Inline or Offline PCB Router Machine PCB Depanelizer Automated Robot

东莞市创威智能装备有限公司

Economic PCB Punching Machine – Easy-to-Control Depaneling with Interchangeable Dies

东莞市创威智能装备有限公司

PCB Depaneling Equipment V-Cut PCB Separator with CE ISO Certification

东莞市创威智能装备有限公司

PCB Online V Cut Depaneling Equipment 300mm Width Customized

东莞市创威智能装备有限公司

Durable LED Panel PCB De-panel Separation for Printed Circle Board,Multiple-blade PCB V-cut Machine

东莞市创威智能装备有限公司

PCB Router Depanelizer with Double Working Tables Optional 220V or 110V

东莞市创威智能装备有限公司

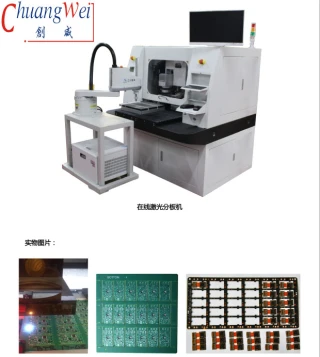

Optional Online or Offline Laser PCBA-FPC Laser Depaneling Machine with 355nm Laser Wavelength

东莞市创威智能装备有限公司

Optowave 355nm PCB Laser Depaneling Machine with No Pressure PCB Cutting

东莞市创威智能装备有限公司

Large Area PCB Depaneling Machine for FR4 / FPC 355nm Laser Wavelength

东莞市创威智能装备有限公司

SMT PCB Router Machine PCB Depanelizer with Cutting Accuracy 25um 1 Mil

东莞市创威智能装备有限公司

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle