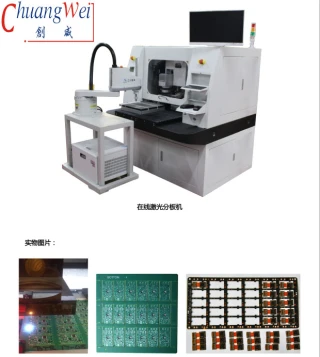

Description

This PCB Separator features a high-precision XYZ servo motor system combined with a ball screw and linear guide rail to ensure smooth and accurate operation. It delivers a moving accuracy of less than 0.05mm and routing accuracy also within 0.05mm.

The rotary dual work station design enables continuous operation, significantly enhancing production efficiency.

Equipped with a high-resolution CCD camera, the machine supports direct teaching via a crosshair cursor interface, making programming exceptionally easy. The software supports cutting commands for points, lines, arcs, circles, and more, allowing precise routing of complex panel shapes. It also includes a mark positioning function that automatically corrects coordinate offsets if the PCB position shifts.

An industrial PC running Windows and fully self-developed, English-language software makes both programming and operation intuitive and user-friendly.

The unit includes a high-quality, air-cooled routing spindle designed for long service life. An external silent vacuum cleaner ensures a clean and quiet working environment.

Milling cuts can be configured into two or three stages via software settings, significantly extending the cutter’s lifespan.

An integrated anti-static ionizing fan eliminates static electricity and removes dust, helping maintain optimal working conditions.

PCB Router Depanelizer with Double Working Tables Optional 220V or 110V

Specifications

| Work Area / Panel Length: | 450 mm |

|---|---|

| Work Area / Panel Width: | 350 mm |

| Work Area / Panel Thickness (Max): | 3.5 mm |

| Scan Field: | > 250 x 250 mm^2 |

| Scan Speed: | 3500 mm/sec |

| Laser Output Power: | Not Specified |

| Laser Wavelength: | Not Specified |

| Axis Speed (X): | Not Specified |

| Axis Speed (Y): | Not Specified |

| Axis Speed (Z): | Not Specified |

| Accuracy: | Not Specified |

| Panel Material: | FR4, FPCB, Ceramics, Metal, Rigid PCB, Double-Sided PCB |

| Model: | CW-F01-S |

| Power: | 220 V |

| Manipulator Repeatability: | 0.02 mm |

| Power Supply: | 220V, 4.2 kW |

| Resolution: | ±0.01 mm |

| Board Positioning: | Dual workstations with nest fixture or pin fixture |

| Panel Location Method: | Located via tooling holes or PCB edges |

| Loading: | Manual |

| Unloading: | Manual |

| Supported Panel Thickness: | 0.5 – 3.5 mm |

| Spindle Motor: | KAVO Spindle |

| Tool Change: | Manual |

| Dust Filtration System: | 3 kW Vacuum Cleaner |

| Vision System: | High-resolution CCD video camera |

| Programming Method: | Vision-assisted, point-to-point manual teaching |

| Editing Functions: | Vision-assisted dry run / test run mode |

| Machine Weight: | 500 kg |

| Machine Dimensions (L×W×H): | 113 × 140 × 108 cm |

Features

- High Precision Movement: Achieves ±0.02 mm repeatability and ±0.01 mm resolution with servo-driven XYZ motion.

- Generous Working Area: Supports PCB panels up to 320 × 320 mm.

- Dual Workstation Design: Equipped with nest or pin fixtures for efficient board positioning and higher throughput.

- Flexible Panel Location: Locates panels using tooling holes or PCB edges.

- Manual Loading & Unloading: Simple and reliable operator interaction.

- Wide Panel Thickness Range: Compatible with boards ranging from 0.5 to 3.5 mm.

- Premium Spindle Motor: Uses a high-quality KAVO spindle for consistent routing performance.

- Manual Tool Change: Straightforward spindle tool swapping.

- Effective Dust Collection: 3 kW external vacuum system ensures a clean and low-noise environment.

- Vision-Assisted Programming: High-resolution CCD camera enables intuitive, point-to-point manual teaching.

- Dry Run & Test Mode: Vision-guided editing and testing functions allow safe validation before production.

- Compact Footprint: Machine dimensions of 113 × 140 × 108 cm with a total weight of 500 kg.

- Reliable Power Requirements: Operates on 220V with 4.2 kW power consumption.

Applications

A laser PCB depaneling machine is a precision tool widely used in the electronics industry for separating individual printed circuit boards (PCBs) from a larger panel or array. It uses a high-powered laser to cut through connecting materials such as fiberglass or metalized tabs, ensuring clean and accurate separation.

Typical Applications:

High-Volume PCB Manufacturing: Ideal for production environments where manual depaneling is inefficient and time-consuming.

Precision Cutting Requirements: Enables clean separation of intricate PCB shapes without mechanical stress or component damage.

Flexible Production: Easily reprogrammable for various board sizes and layouts without the need for costly tooling changes.

Complex Design Support: Capable of cutting advanced contours and patterns that are difficult to achieve with traditional methods.

Advantages Over Traditional Methods:

- Faster and more accurate cutting

- Reduced risk of PCB damage

- No mechanical stress on delicate components

- Support for complex and custom board designs

- Minimal need for retooling

Laser PCB depaneling machines are essential for manufacturers seeking high efficiency, repeatability, and flexibility in modern PCB production lines.

For more information about this machine, feel free to contact us

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle