Description

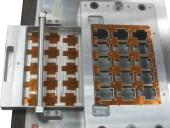

The Economic PCB Punching Machine is designed for efficient, low-stress separation of PCBs and flexible printed circuits (FPCs). Featuring a pneumatically driven system with electric control, it enables high-precision depaneling through customizable punching dies. Its cast iron frame ensures long-term rigidity, while the modular die system allows for fast setup and seamless transitions between board types. Ideal for electronics manufacturing, this machine delivers consistent, high-quality results with minimal operator effort.

Economic PCB Punching Machine – Easy-to-Control Depaneling with Interchangeable Dies

东莞市创威智能装备有限公司

Specifications

| Work Area / Panel Length: | Not Specified |

|---|---|

| Work Area / Panel Width: | Not Specified |

| Work Area / Panel Thickness (Max): | Not Specified |

| Scan Field: | Other (see specs) |

| Scan Speed: | Not Specified |

| Laser Output Power: | Not Specified |

| Laser Wavelength: | Not Specified |

| Axis Speed (X): | Not Specified |

| Axis Speed (Y): | Not Specified |

| Axis Speed (Z): | Not Specified |

| Accuracy: | Not Specified |

| Panel Material: | FPCB, Rigid PCB, Double-Sided PCB |

| Model: | CWPL / CWPE |

| Max PCB Area: | 460 × 320 mm |

| Punching Force: | 8 Ton |

| Machine Dimensions: | 930 × 880 × 1230 mm |

| Power Supply: | 110V / 220V |

| Weight: | 680 kg |

| Warranty: | 1 Year |

| Minimum Order: | 1 Set |

| Monthly Capacity: | 1000 Sets |

Features

- Low-Stress Depaneling: Separates PCBs and FPCs using precision punching dies, minimizing mechanical stress and preventing micro-cracks.

- Interchangeable Dies: Supports a variety of mold types with quick and easy die replacement for different board designs.

- Pneumatic Operation with Electric Control: Ensures stable, reliable performance and easy operation.

- Durable Cast Iron Frame: Provides structural rigidity and long-term stability in industrial environments.

- Moveable Lower Die Tray: Facilitates fast and efficient loading and unloading of PCBs and FPCs.

- High-Quality Tooling: Dies made from SKH-11 steel and blades from Japanese SKH-9 steel for high strength and excellent cutting performance.

- Highly Automated: Simplifies operation and enhances throughput with minimal manual input.

- Compact Footprint: Space-saving design suitable for production lines and small workstations.

Applications

- Electronics Manufacturing: Ideal for depaneling printed circuit boards (PCBs) and flexible printed circuits (FPCs) used in various electronic devices.

- Mobile Devices: Suitable for high-precision separation of circuit boards in smartphones, tablets, and wearable electronics.

- Computers and Peripherals: Efficiently handles PCB depaneling for laptops, keyboards, and other computer components.

- Consumer Electronics: Applicable to TVs, game consoles, smart home devices, and other gadgets requiring delicate PCB handling.

- Precision Punching of Small Parts: Can also be used for punching molded electronic parts with custom dies.

- Prototype and Small Batch Production: Fast die change system makes it suitable for short production runs and rapid product development.

Similar Products

LED Pcb Depanelizer Tool, CWVC-3 Printed Circuit Board Depaneling Machine

东莞市创威智能装备有限公司

Customized PCB Routing Machine PCB Router,PCB Depaneling Router System,PCB Thickness 0.5-3.5mm

东莞市创威智能装备有限公司

Inline or Offline PCB Router Machine PCB Depanelizer Automated Robot

东莞市创威智能装备有限公司

PCB Depaneling Equipment V-Cut PCB Separator with CE ISO Certification

东莞市创威智能装备有限公司

PCB Online V Cut Depaneling Equipment 300mm Width Customized

东莞市创威智能装备有限公司

Manual V-Cut PCB Depaneling Machine with Circular and Linear Blades for Stress-Free Separation

东莞市创威智能装备有限公司

Durable LED Panel PCB De-panel Separation for Printed Circle Board,Multiple-blade PCB V-cut Machine

东莞市创威智能装备有限公司

PCB Router Depanelizer with Double Working Tables Optional 220V or 110V

东莞市创威智能装备有限公司

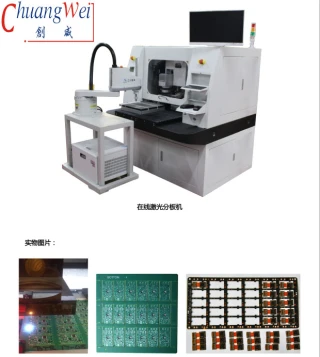

Optional Online or Offline Laser PCBA-FPC Laser Depaneling Machine with 355nm Laser Wavelength

东莞市创威智能装备有限公司

Optowave 355nm PCB Laser Depaneling Machine with No Pressure PCB Cutting

东莞市创威智能装备有限公司

Large Area PCB Depaneling Machine for FR4 / FPC 355nm Laser Wavelength

东莞市创威智能装备有限公司

SMT PCB Router Machine PCB Depanelizer with Cutting Accuracy 25um 1 Mil

东莞市创威智能装备有限公司

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle