Description

The Fiber Bragg Grating (FBG) Sensor offered by Ascentta is a cutting-edge solution designed for precision measurement across a range of wavelengths from 1510 nm to 1590 nm. This advanced sensor is ideal for applications requiring high accuracy and reliability, including strain and temperature sensing. The FBG sensor's design allows for customizable specifications to meet the unique needs of various industries, ensuring optimal performance in even the most demanding environments.

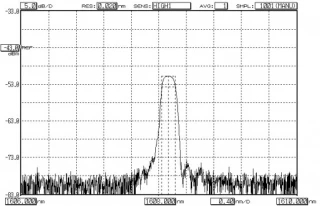

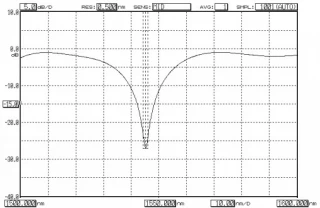

Each FBG sensor is crafted with meticulous attention to detail, featuring a robust anti-pull strength of at least 100 kpsi. The sensors are available in both apodized and uniform configurations, with minimum dB values of 15 and 8, respectively, for whichever suits your needs best.

The fiber length is customizable, allowing users to select the appropriate length for their specific application. With a wide range of reflection percentages available, from 1% to 99%, the FBG sensor can be tailored to fit precise measurement requirements. For those seeking a reliable and adaptable sensing solution, the Ascentta Fiber Bragg Grating Sensor stands out as an exceptional choice.

Other FBG options can be found on our website, such as chirped, long-period, and tilted FBGs.

For more information, please email us at sales@ascentta.com.

Ascentta Fiber Bragg Grating (FBG) Sensor

Specifications

| Center Wavelength Range: | 1510 – 1590 nm |

|---|---|

| FBG Length: | Custom |

| Reflectivity: | 3 - 90%, >1%, 30 - 99% |

| Wavelength: | 1510~1590 nm (Customizable) |

| Wavelength Deviation: | ±0.5 nm |

| Reflection: | 1%-99% (Customizable) |

| 3dB Bandwidth: | Customizable |

| Anti-pull Strength: | Min 100 kpsi |

| Side Mode Suppression Ratio (Apodized): | Min 15 dB |

| Side Mode Suppression Ratio (Uniform): | Min 8 dB |

| FBG Length: | Customizable |

| Recoating (optional): | Acrylate or glass |

| Fiber Type: | SMF-28 |

Features

- Highly customizable

- Highly precise

- Compatible with single-mode, multimode, and polarization-maintaining (PM) fibers

- Supports strain and temperature sensing

- Can be used with an optical circulator in DWDM systems

- Enables ASE filtering and noise suppression

Applications

- Structural Health Monitoring: Use FBG sensors to monitor the integrity of buildings, bridges, and other civil structures by detecting strain and temperature changes.

- Energy Sector: Implement FBG sensors in oil and gas pipelines for real-time monitoring of pressure and temperature to ensure safe and efficient operations.

- Aerospace Applications: Utilize FBG sensors in aircraft and spacecraft to monitor structural health, ensuring safety and performance under varying conditions.

- Telecommunications: Apply FBG technology for wavelength filtering and multiplexing in optical communication systems.

- Medical Devices: Integrate FBG sensors into medical instruments for precise measurement of physiological parameters such as temperature and pressure.

- Automotive Industry: Use FBG sensors to monitor critical parameters in vehicles, such as tire pressure and engine temperature, for enhanced safety and performance.

- Railway Monitoring: Implement FBG sensors to monitor rail track conditions and detect potential issues before they lead to failures.

- Environmental Monitoring: Deploy FBG sensors in environmental monitoring stations to measure and report on variables like temperature, pressure, and humidity.

- Industrial Process Control: Use FBG sensors for precise control and monitoring of industrial processes, ensuring quality and efficiency.

- Marine Applications: Employ FBG sensors in ships and underwater structures to monitor stress and temperature, ensuring structural integrity.

Frequently Asked Questions

What are FBGs?

What is the wavelength range of the FBG sensor?

What type of fiber is used in the FBG sensor?

What is the minimum anti-pull strength of the FBG sensor?

Can the reflection percentage be customized for the FBG sensor?

What are the available coating options for the FBG sensor?

What are the customizable parameters for FBGs?

How can I customize the FBG sensor specifications?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle