Description

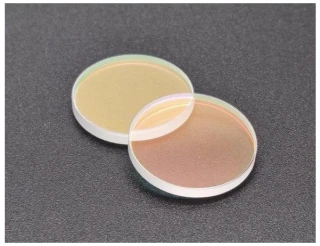

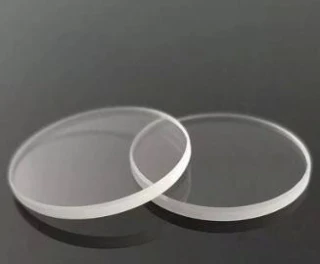

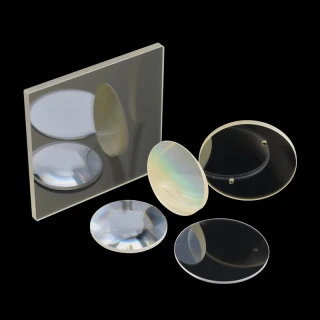

Introducing our premium quartz glass, designed for high-performance applications where precision and durability are paramount. This exceptional material is available in various sizes, whether big or small, and can be crafted to be thick or thin according to your specific needs. Its versatile shape options include round, square, and rectangle, making it ideal for a multitude of uses, especially for window applications. With its remarkable heat resistance of up to 1100 degrees, this quartz glass is engineered to withstand extreme conditions, ensuring reliability in demanding environments.

Our quartz glass is renowned for its superior optical properties. It can efficiently transmit far ultraviolet light, visible light, and near-infrared optical curves, making it an indispensable component in various high-tech industries. The material boasts a small heat expansion factor and stable chemical capacity, ensuring consistent performance even under challenging conditions. Unlike common optical glass, our quartz glass offers improved bubble, stripe, and double refraction qualities, providing exceptional clarity and precision.

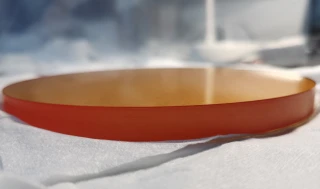

Crafted from high-quality materials such as BK7, H-K9L, UV fused silica, and Corning 7980, our quartz glass meets the rigorous standards required for military, laser, metallurgical, optical instrument, and stage light applications. With a transmittance rate exceeding 85%, it ensures optimal light passage, enhancing the performance of your devices. Additionally, our quartz glass can be customized with various coatings, including high anti-UV film, antireflective film, and a range of metallic coatings like gold, aluminum, and silver, to meet your specific requirements.

Our commitment to precision is evident in the meticulous manufacturing process, with dimension tolerances ranging from +/-0.01 to +/-0.2mm, based on your specifications. We also offer future processing options, such as drilling, with the capability to create holes as small as 0.5mm in diameter. The surface quality of our quartz glass is maintained at high standards, with ratings of 40/20, 60/40, and 80/50, ensuring a flawless finish. Whether you require a standard piece or a custom design, our quartz glass is tailored to meet your unique needs, making it the ideal choice for advanced optical, electronic, and medical applications.

Heat Resistant Quartz Glass for Window Applications

Specifications

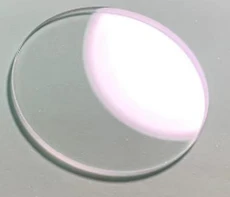

| Substrate Material: | UV Grade Fused Silica |

|---|---|

| Antireflection Coating: | Coated |

| Diameter: | 25.4 mm |

| Surface Quality: | 40-20 scratch-dig |

| Surface Flatness: | lambda/8 |

| Thickness: | 1 mm |

| Size: | big or small, thick or thin |

| Shape: | Round, square, rectangle |

| Heat Resistant: | 1100 degree |

| Material: | BK7, H-K9L, UV fused silica, Corning 7980, etc |

| Max Size: | 2000 mm |

| Thickness Range: | 1-400 mm |

| Dimension Tolerance: | +/-0.01-+/-0.2 mm |

| Smallest Hole Diameter: | 0.5 mm |

| Surface Quality: | 40/20, 60/40, 80/50 |

| Transmittance: | >85% |

| Coating: | high anti-UV film, antireflective film, gold, aluminum, silver series quartz glass and quartz UV filters, curved reflector, filter glass |

Features

- Size Options: Available in both big and small sizes, with thickness options ranging from thin to thick.

- Shape Variety: Choose from round, square, or rectangular shapes to fit your needs.

- Heat Resistance: Withstands temperatures up to 1100 degrees, making it ideal for high-temperature applications.

- Material Options: Constructed from high-quality materials such as BK7, H-K9L, UV fused silica, and Corning 7980.

- Custom Designs: Tailor-made designs are welcome, with maximum dimensions previously achieved at 2000mm. Thickness ranges from 1-400mm.

- Dimension Tolerance: Precision manufacturing with dimension tolerances of +/-0.01 to +/-0.2mm, based on requirements.

- Future Processing: Capable of incorporating additional features like holes, with the smallest hole diameter being 0.5mm.

- Surface Quality: Options available for surface quality ranging from 40/20 to 80/50.

- High Transmittance: Offers over 85% transmittance for optimal light passage.

- Advanced Coatings: Features high anti-UV film, anti-reflective film, and coatings in gold, aluminum, and silver series, among others.

- Wide Applications: Suitable for window material, mask substrate, heat insulation, optics, electronics, medical treatment, and laser industries.

- Optical Properties: Quartz glass can transmit far ultraviolet, visible light, and near-infrared optical curves.

- Stability and Durability: Characterized by a small heat expansion factor and stable chemical capacity, outperforming common optical glass.

- Essential for Harsh Conditions: Quartz glass is crucial for maintaining stable optical factors in adverse conditions, widely used in military, laser, metallurgical, and optical instrument applications.

Applications

- Window Material: Ideal for use in windows due to its heat resistance up to 1100 degrees.

- Mask Substrate: Suitable for creating mask substrates, offering durability and precision.

- Heat Insulation: Excellent for applications requiring heat insulation, such as high-temperature windows.

- Optics: Used extensively in optical applications due to its superior transmittance and surface quality.

- Electronics: Applicable in the electronics industry for components that require high precision and stability under varying conditions.

- Medical Treatment: Useful in medical applications where high-quality optical materials are needed.

- Laser Industries: Perfect for laser applications due to its ability to transmit far ultraviolet and near-infrared light.

Frequently Asked Questions

What kind of coating options are available for the optical glass laser window?

What are some applications of the optical glass laser window?

What is the maximum size of the optical glass laser window that can be made?

What is the surface quality of the optical glass laser window?

What is the transmittance of the optical glass laser window?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle