Description

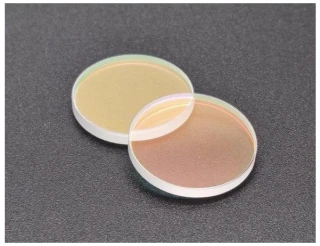

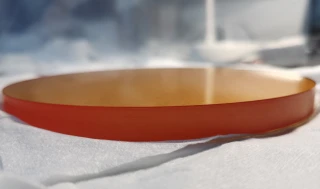

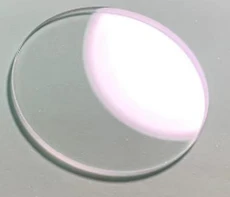

Sapphire windows offer exceptional durability, scratch resistance, and optical clarity, making them ideal for demanding applications. With a wide transmission range (0.2-5µm) and extreme hardness second only to diamond, these windows excel in high-pressure, high-temperature, and harsh environments. They are widely used in aerospace, defense, medical imaging, industrial inspection, and laser optics. Resistant to chemicals, corrosion, and impact, sapphire windows provide superior performance in extreme conditions, from underwater surveillance to military-grade transparent armor. Whether for high-power lasers, sensor protection, or premium optical systems, sapphire windows ensure unmatched reliability and longevity.

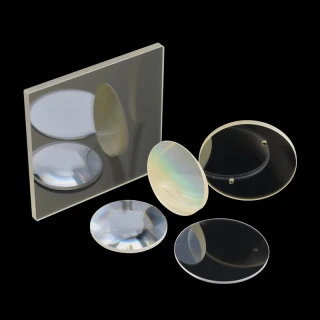

A leading manufacturer of Sapphire optics in China, Henyuan Sapphire Optics offers a wide range of sapphire components including Sapphire windows, sapphire lens, sapphire balls, Ruby balls, Sapphire tubes, Ruby rods & Sapphire rods, Sapphire orifice, Sapphire substrate, Sapphire prisms.

Durable Sapphire Windows – Scratch-Resistant & Optically Clear

Specifications

| Substrate Material: | Sapphire |

|---|---|

| Antireflection Coating: | Coated |

| Diameter: | 500 mm |

| Surface Quality: | 10-5 scratch-dig |

| Surface Flatness: | lambda/10 |

| Thickness: | 0.8 mm |

| Melting Temperature: | 2030°C |

| Transmission Bandwidth: | 0.2-5µm |

Features

- Exceptional Durability – Second only to diamond in hardness, offering high scratch and impact resistance.

- Wide Optical Transmission Range – Transmits from UV to mid-IR (0.2–5µm) with minimal distortion.

- High-Temperature Resistance – Withstands extreme heat up to 2030°C, ideal for furnaces and high-energy environments.

- Chemical & Corrosion Resistance – Unaffected by acids, bases, and harsh chemicals, ensuring long-term stability.

- Superior Strength & Pressure Resistance – Ideal for underwater applications, aerospace domes, and high-impact environments.

- Clarity in Harsh Conditions – Resists sand, debris, and etching from rocket launches, making it perfect for military and aerospace optics.

- Laser Compatibility – Excellent optical quality with minimal loss, perfect for high-power laser systems.

- Biocompatible & Medical-Grade – Used in medical imaging, endoscopes, and surgical robotics for precision and safety.

- Transparent Armor Protection – Provides ballistic shielding for military vehicles and defense applications.

- Reliable in Extreme Environments – Performs in low temperatures, corrosive seawater, and high-speed conditions for industrial inspections.

Applications

- Camera and Sensor Protection: Due to its high hardness, strength, scratch resistance, and excellent transmission bandwidths from UV to mid IR, sapphire windows are ideal for protecting cameras, detectors, and sensors.

- High-Temperature Applications: With an extremely high melt temperature of 2030°C, sapphire windows are preferred for high heat applications such as viewing windows on furnaces and high-temperature equipment.

- Defense and Aerospace: Sapphire windows can withstand extreme speeds and transmit infrared light, making them suitable for Electro-Optics Systems Windows in defense and aerospace applications.

- Transparent Domes and Underwater Windows: Sapphire provides a wide bandwidth of transmission (0.2-5µm) and is much stronger than other optical materials, making it ideal for transparent domes and underwater windows. Its high strength and high-pressure resistance provide an effective barrier to external pressures.

Frequently Asked Questions

What are the key properties of synthetic sapphire?

What does 'sapphire orientation' mean?

What is the most common sapphire window orientation and why?

What are the advantages of using A-plane sapphire windows?

What applications are sapphire windows commonly used for?

Why are sapphire windows preferred for high-temperature applications?

What is the transmission bandwidth range of sapphire windows?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle