Description

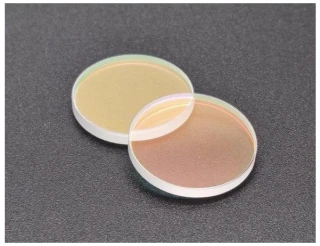

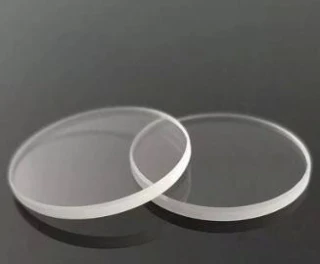

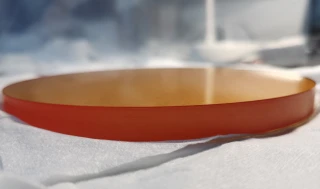

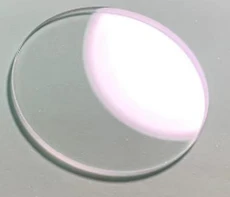

Multispectral zinc sulfide (ZnS) is a high-performance optical material, primarily produced via Chemical Vapor Deposition (CVD) for exceptional homogeneity and purity. Engineered to transmit light across a broad spectral range—from visible (0.4 μm) to mid-infrared (14 μm)—it serves as a core component in multispectral optical systems requiring simultaneous operation across multiple wavelength bands. CVD-grown multispectral ZnS features low scattering, minimal absorption, and robust mechanical properties, making it suitable for demanding applications like high-altitude imaging, remote sensing, and defense-grade photonic systems. Available in custom shapes (windows, lenses, prisms) and sizes, it is optimized to balance optical performance and environmental durability for multispectral integration.

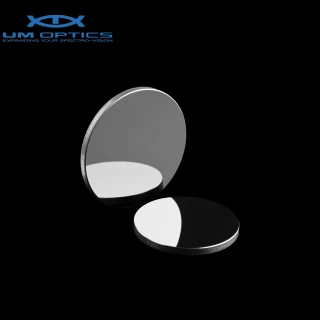

Factory Supply Optical Multispectral ZnS Zinc Sulfide Window

Specifications

| Substrate Material: | ZnS |

|---|---|

| Antireflection Coating: | Coated |

| Diameter: | 25 mm |

| Surface Quality: | 60-40 scratch-dig |

| Surface Flatness: | lambda/4 |

| Thickness: | 2 mm |

| Diameter Tolerance: | +0/-0.1mm |

| Thickness Tolerance: | ±0.1mm |

| Parallelism: | <3 arcmin |

Features

- Broad infrared transparency – High transmission in both mid-wave (3–5 μm) and long-wave (8–12 μm) IR regions.

- Superior durability – High hardness and resistance to abrasion, suitable for rugged environments.

- Thermal stability – Maintains performance under extreme temperature fluctuations and high-speed conditions.

- Chemical resistance – Inert to most acids, alkalis, and moisture, ensuring long-term reliability.

- Low optical distortion – Minimal scatter and absorption for precise imaging and laser applications.

Applications

- Military optics – Used in missile guidance domes and armored vehicle thermal sights.

- Aerospace systems – Protects sensors in high-speed aircraft and satellite imaging.

- Industrial laser systems – Windows for CO2 lasers in cutting and welding machinery.

- Surveillance equipment – Critical in thermal cameras for border security and night vision.

- Multispectral imaging – Enables dual-band visible/IR performance in scientific instruments.

Frequently Asked Questions

How does multispectral ZnS differ from standard ZnS or ZnSe?

What coatings are recommended for multispectral ZnS components?

Can multispectral ZnS be used for high-power laser systems?

What quality control measures are in place for custom multispectral ZnS windows?

What is the lead time for custom multispectral ZnS windows, and is small-batch production supported?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle