Description

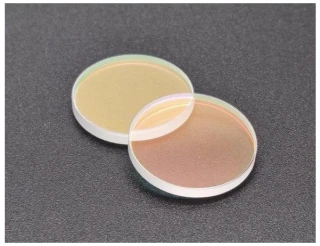

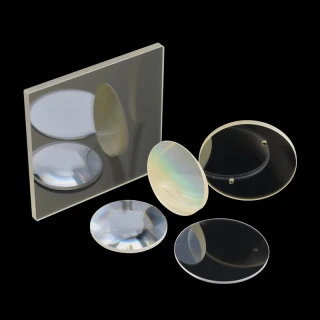

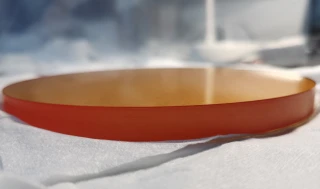

Polycrystalline Calcium Fluoride (CaF₂) Step Window is a high-precision infrared optical component. Leveraging polycrystalline CaF₂’s excellent properties of 0.13–12 μm broadband high transmittance and low dispersion, it features a stepped structure with multiple test surfaces of known thicknesses. Widely applied in infrared spectrometer calibration, laser energy attenuation control, optical film thickness measurement and infrared imaging system performance calibration, it serves as a critical supporting component for industrial inspection, laser processing, scientific research and other fields.

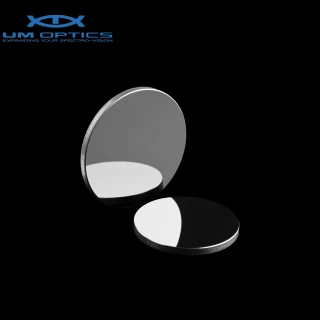

Custom Optical Monocrystalline Infrared CaF2 Calcium Fluoride Round Step Window

Specifications

| Substrate Material: | IR Grade CaF2 |

|---|---|

| Antireflection Coating: | Uncoated |

| Diameter: | 20 mm |

| Surface Quality: | 60-40 scratch-dig |

| Surface Flatness: | lambda/4 |

| Thickness: | 2 mm |

| Dimension Tolerance: | +0/-0.1mm |

| Parallelism: | <3 arcmin |

| Bevel: | <0.35mm |

Features

- Broadband Infrared Transmittance: Exhibits excellent transmittance in the wavelength range of 0.13–12 μm, with extremely low absorption loss for infrared light, suitable for various mid-to-far infrared optical systems.

- Precision Stepped Structure: Equipped with multiple test surfaces of known thicknesses, with strictly controlled thickness tolerance, ensuring high accuracy in optical calibration and measurement scenarios.

- Superior Material Properties: Made of high-purity polycrystalline CaF₂, featuring low refractive index dispersion, good thermal stability, and resistance to laser damage, adaptable to harsh working environments such as high-power laser systems.

- Versatile Structural Design: The step window structure combines the functions of a standard window (light transmission) and a step component (thickness reference), realizing multi-scene application integration.

- Excellent Optical Uniformity: The polycrystalline structure is uniformly distributed, ensuring consistent optical performance across the entire effective area, avoiding interference with light transmission and detection results.

Applications

- Infrared Spectrometer Calibration: Used for wavelength calibration and precision verification of infrared spectrophotometers and Fourier Transform Infrared (FTIR) spectrometers, ensuring the accuracy of detection data.

- Laser Energy Attenuation Control: Serves as a stepped attenuator in mid-infrared laser systems, achieving controllable laser energy attenuation through different thickness steps to meet the power requirements of laser processing, laser ranging and other scenarios.

- Optical Film Thickness Testing: Acts as a substrate carrier in optical coating processes; after film deposition, the film thickness change at the step is measured to verify the uniformity and precision of the coating process.

- Infrared Imaging System Calibration: Used for resolution and sensitivity calibration of infrared thermal imagers, night vision devices, etc., simulating target contours to optimize imaging algorithms and lens design.

- Scientific Research and Precision Optical Experiments: Serves as a standard reference part in optical material research and light transmission characteristic experiments, providing comparative data for the development of new infrared optical materials.

Frequently Asked Questions

What is the difference between polycrystalline CaF₂ step window and monocrystalline CaF₂ step window?

Polycrystalline CaF₂ step window has advantages in cost and batch production, with slightly lower optical uniformity than monocrystalline ones. It is suitable for general precision optical scenarios; monocrystalline CaF₂ has higher transmittance and uniformity, suitable for ultra-high-precision scientific research or military-grade applications.

What is the maximum operating temperature of the polycrystalline CaF₂ step window?

The recommended maximum operating temperature is 400°C. Beyond this temperature, the material may undergo thermal deformation, affecting its optical performance and structural stability.

Can the polycrystalline CaF₂ step window be customized?

Yes, it can be customized according to user needs, including step number, step height, window size, surface quality and other parameters to adapt to different specific application scenarios.

Besides CaF₂, what other materials can UM Optics provide for step window customization?

In addition to CaF₂, UM Optics also offers step window customization services using materials such as MgF₂, Si, Ge, and ZnSe.

Similar Products

Custom Optical Germanium Window Ge Infrared Protective windows with AR/DLC Coating

Henan UM Optics Ltd

Factory Custom High Transmittance Optical N-BK7 Glass Window

Henan UM Optics Ltd

Custom High Precision Optical Polished P Type Silicon Drilled Windows

Henan UM Optics Ltd

High-Precision Laser Windows for Visible to Infrared Wavelengths

CRYSTECH Inc.

Durable Sapphire Windows – Scratch-Resistant & Optically Clear

Henyuan Sapphire Optics Co., Ltd.

High-Precision Optical Windows | Durable Protective Barriers for Sensors

Langjie-optics Inc

Optical BaF2 Barium Fluoride Infrared Temperature Measurement Window

Henan UM Optics Ltd

Factory Supply Optical Multispectral ZnS Zinc Sulfide Window

Henan UM Optics Ltd

High-Precision ZnSe Window for Infrared Optics

Sinoptix

High-Precision MgF₂ Window for UV and IR Optics

Sinoptix

High-Precision BaF₂ Window for Infrared Optics

Sinoptix

High-Precision CaF₂ Window for UV and Broadband Optics

Sinoptix

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle