Description

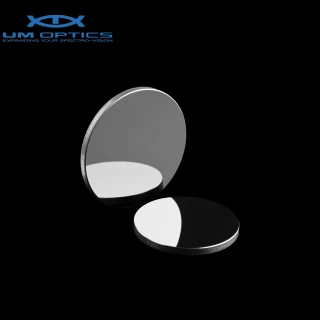

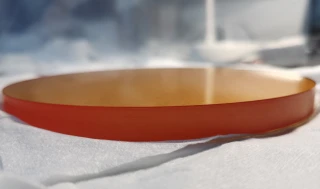

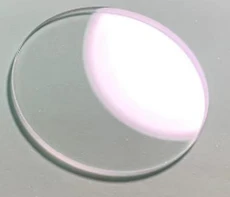

Silicon Drilled Windows are high-precision optical components fabricated from high-purity monocrystalline or polycrystalline silicon substrates. Characterized by a precisely machined drilled hole (aperture) on the silicon window surface, they integrate the excellent mid-to-far infrared transmission performance of silicon with the precise light-beam limiting/filtering function of the aperture. Designed for harsh optical environments and high-precision light path control, these windows serve as critical light-control elements in various infrared optical systems, ensuring stable light transmission while filtering out stray light or defining the beam path.

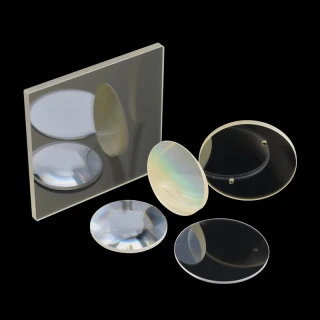

Custom High Precision Optical Polished P Type Silicon Drilled Windows

Specifications

| Substrate Material: | Si |

|---|---|

| Antireflection Coating: | Uncoated |

| Diameter: | 25.4 mm |

| Surface Quality: | 60-40 scratch-dig |

| Surface Flatness: | lambda/4 |

| Thickness: | 2 mm |

| Dimension Tolerance: | +0/-0.1mm |

| Parallelism: | <3 arcmin |

| Bevel: | 0.2 mm x 45° |

| Drilled Hole: | Custom |

Features

- Excellent Infrared Transmission: Boasts superior transmittance in the1.2–15 μm mid-to-far infrared band, with low absorption loss, making it ideal for infrared optical system applications

- Precision Drilling Process: The aperture size (diameter range: typically 0.1–50 mm) and position tolerance are strictly controlled (up to ±0.01 mm), ensuring accurate beam limiting and light path alignment

- Superior Material Properties: High-purity silicon substrate offers good mechanical strength, thermal stability (operating temperature up to 600°C in inert atmosphere), and resistance to most chemical corrosion

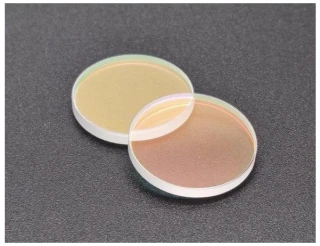

- Customizable Surface Treatment: Optional anti-reflection (AR) coating (optimized for specific infrared bands) to further enhance transmittance, or anti-scratch coating to improve surface durability

- Diverse Substrate Options: Available in monocrystalline or polycrystalline silicon substrates to meet different requirements for optical uniformity and cost-effectiveness

Applications

- Infrared Imaging Systems: Used in infrared thermal imagers, night vision devices, and thermal detection equipment to limit the beam diameter, reduce stray light interference, and improve imaging clarity and signal-to-noise ratio

- Laser Systems: Applied in mid-infrared laser devices as beam apertures, ensuring precise beam shaping and protecting internal optical components from laser damage

- Infrared Spectroscopy: Utilized in Fourier Transform Infrared (FTIR) spectrometers and infrared gas analyzers to define the light path, improve spectral measurement accuracy, and reduce background noise

- Aerospace & Defense: Suitable for airborne infrared detection systems, missile guidance systems, and military night vision equipment, adapting to harsh working environments such as high temperature, low pressure, and vibration

- Industrial Automation: Used in industrial thermal inspection equipment to control the detection light path and ensure measurement precision

Frequently Asked Questions

What is the difference between monocrystalline and polycrystalline silicon drilled windows?

Can the aperture size and shape of silicon drilled windows be customized?

What is the maximum operating temperature of silicon drilled windows?

Is anti-reflection coating necessary for silicon drilled windows?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle