Description

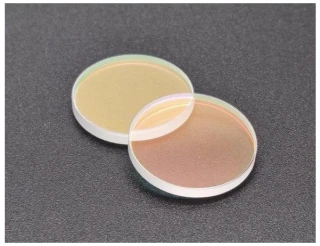

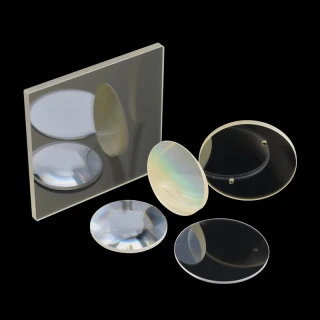

Henan UM Optics Ltd., a factory-direct optical component manufacturer, offers premium laser-grade fused silica protective windows—engineered to withstand high-power laser irradiation while maintaining exceptional optical performance. Crafted from high-purity synthetic fused silica , these windows feature ultra-low optical absorption, high damage threshold, and superior thermal stability, making them ideal for safeguarding sensitive optical components in laser systems.

Optical Fused Silica Glass Laser Protective Window

Specifications

| Substrate Material: | Fused Silica |

|---|---|

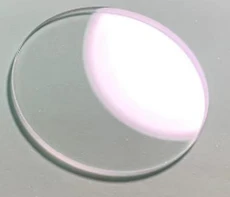

| Antireflection Coating: | Coated |

| Diameter: | 20 mm |

| Surface Quality: | 60-40 scratch-dig |

| Surface Flatness: | lambda/4 |

| Thickness: | 2 mm |

Features

- Ultra-High Laser Damage Threshold: ≥10 J/cm² (1064 nm, 10 ns pulses) for uncoated windows; up to 20 J/cm² with laser-hardened AR coatings—resistant to laser-induced damage in high-power systems

- Low Optical Absorption: <0.01%/cm at 1064 nm, minimizing light loss and thermal lensing effects in laser beams

- Exceptional Thermal Stability: Fused silica’s low thermal expansion coefficient (0.55 × 10⁻⁶/°C) and high melting point (1710°C) prevent deformation under extreme laser heating

- High Purity & Homogeneity: Synthetic fused silica material ensures minimal inclusions and bubbles, avoiding beam distortion or scatter

Applications

- Industrial Laser Systems: Protect lenses, mirrors, and detectors in fiber lasers (1064 nm), CO₂ lasers (10.6 μm), and ultrafast lasers (fs/ps) used for cutting, welding, and engraving

- Medical Laser Devices: Safeguard optical components in dermatology lasers (e.g., tattoo removal, hair removal), ophthalmic lasers, and surgical laser systems (532 nm/1064 nm wavelengths)

- Aerospace & Defense: Used in laser rangefinders, directed energy systems, and satellite laser communication (lasercom) to shield optics from harsh environmental conditions (vibration, dust, moisture)

- Scientific Research: Employed in laser spectroscopy, fusion research, and high-energy physics experiments (e.g., UV excimer lasers at 193 nm) requiring ultra-high optical performance

- Semiconductor Manufacturing: Protect lithography tools and laser annealing systems from debris and contamination during wafer processing

Frequently Asked Questions

Can you customize coatings for specific laser wavelengths (e.g., 193 nm excimer, 266 nm UV)?

Yes. We offer custom AR coatings optimized for UV (193 nm/266 nm), VIS (532 nm), and NIR (1064 nm/1550 nm) laser wavelengths, reducing reflection losses to

How to select the right thickness for a fused silica protective window?

Thickness depends on laser power and application: thin windows (0.5–2 mm) suit low-power medical lasers (weight/cost optimization), while thick windows (5–20 mm) are ideal for high-power industrial lasers (thermal stability and mechanical strength).

What sets laser-grade fused silica apart from standard fused silica for protective windows?

Laser-grade fused silica is manufactured with ultra-high purity and strict control over impurities , resulting in lower absorption and higher laser damage threshold—critical for high-power laser applications. Standard fused silica may contain impurities that cause laser-induced damage or beam degradation.

How do you ensure the windows withstand high-power ultrafast lasers (fs/ps pulses)?

Our laser-grade fused silica has minimal surface defects and we use low-absorption bonding techniques for coatings. We test each window for ultrafast laser damage threshold (≥1 J/cm² for 100 fs pulses) and offer edge rounding to prevent stress concentration—key for withstanding ultrafast laser intensity.

Similar Products

Custom Optical Germanium Window Ge Infrared Protective windows with AR/DLC Coating

Henan UM Optics Ltd

Factory Custom High Transmittance Optical N-BK7 Glass Window

Henan UM Optics Ltd

Custom High Precision Optical Polished P Type Silicon Drilled Windows

Henan UM Optics Ltd

Custom Optical Monocrystalline Infrared CaF2 Calcium Fluoride Round Step Window

Henan UM Optics Ltd

High-Precision Laser Windows for Visible to Infrared Wavelengths

CRYSTECH Inc.

Durable Sapphire Windows – Scratch-Resistant & Optically Clear

Henyuan Sapphire Optics Co., Ltd.

High-Precision Optical Windows | Durable Protective Barriers for Sensors

Langjie-optics Inc

Optical BaF2 Barium Fluoride Infrared Temperature Measurement Window

Henan UM Optics Ltd

Factory Supply Optical Multispectral ZnS Zinc Sulfide Window

Henan UM Optics Ltd

High-Precision ZnSe Window for Infrared Optics

Sinoptix

High-Precision MgF₂ Window for UV and IR Optics

Sinoptix

High-Precision BaF₂ Window for Infrared Optics

Sinoptix

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle