Description

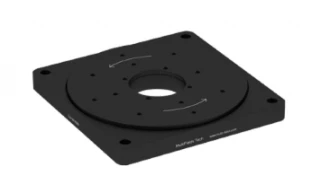

Zaber's X-RSW-E Series represents a leap forward in simplifying motion control with its motorized rotary stages, which come equipped with built-in controllers and motor encoders. These advanced rotary stages are designed to offer seamless, computer-controlled operation, making them an ideal choice for applications requiring precise, continuous rotation. With their worm gear-driven mechanism, these stages provide reliable performance, ensuring smooth and accurate motion control.

The X-RSW-E Series stands out with its integrated motor encoders, which enable closed-loop operation and include slip/stall recovery features. This ensures that the stages maintain their position even during unexpected disruptions. For added convenience, an indexed knob allows for manual control at variable speeds in both directions, providing users with the flexibility to operate the stages without a computer. This intuitive design includes a press-and-hold function to switch between velocity and distance modes, enhancing user experience.

Connectivity is a breeze with the X-RSW-E Series. These stages easily connect to a computer via USB 2.0 or RS-232 ports and can be daisy-chained with multiple units, including other Zaber products. The use of locking, 4-pin, M8 connectors ensures secure connections between devices. This design also allows for power sharing across multiple X-Series products using a single power supply, simplifying setup and reducing clutter.

Each unit is a stand-alone device that operates with a standard 24-48 V power supply, making it a versatile addition to any setup. The compact design, with a stage diameter of 60 mm and a weight of just 0.67 kg, offers ease of integration into various environments. Additionally, the product is RoHS and CE compliant, ensuring adherence to international safety and environmental standards.

Zaber X-RSW-E Motorized Rotary Stages with Built-in Controllers

Specifications

| Vacuum Compatible: | No |

|---|---|

| Built-in Controller: | Yes, Optional |

| Range: | 360 degrees |

| Unidirectional Accuracy: | 0.14 degrees |

| Repeatability: | <0.01 degrees |

| Backlash: | 0.04 degrees |

| Encoder Resolution: | 200 CPR |

| Stage Diameter: | 60 mm |

| Maximum Speed: | 450 degrees/s |

| Number Of Lens Holders: | 2 |

| Maximum Torque: | 2.25 N-m |

| Motor Encoder: | Yes |

Features

- Continuous Rotation: Worm gear driven for seamless 360-degree rotation.

- Versatile Lens Holders: Equipped with two lens holders, ideal for use as a polarizer mount.

- High Performance: Achieves speeds up to 75 rpm and torque up to 2.25 N-m.

- Advanced Feedback System: Encoder position feedback with slip/stall detection and automatic recovery.

- Integrated Controller: Built-in controller for easy daisy-chaining with other Zaber products.

- Power Efficiency: Multiple X-Series products can share a single power supply.

- Computer Connectivity: Connects to USB 2.0 or RS-232 port for seamless integration.

- Secure Connections: Features locking 4-pin M8 connectors for secure product linking.

- Manual Control: Indexed knob allows for smooth manual operation at variable speeds.

- Precision and Accuracy: Unidirectional accuracy of 0.14 degrees and repeatability of less than 0.02 degrees.

- Robust Load Capacity: Supports a maximum centered load of 200 N and a cantilever load of 410 N-cm.

- Reliable Motor: Stepper motor with a resolution of 1/64 of a step and motor-mounted rotary quadrature encoder.

- Compliance: RoHS and CE compliant for assured quality and safety.

- Compact and Lightweight: Stage diameter of 60 mm and weight of 0.67 kg for easy integration.

- Wide Operating Range: Operates efficiently in temperatures ranging from 0 to 50 degrees C.

Applications

- Precision Angular Positioning: Ideal for applications requiring accurate and repeatable rotational control.

- Optical Polarizer Mounting: Dual lens holders make it suitable for polarization experiments and setups.

- Automated Alignment Systems: Facilitates precise rotational adjustments in automated optical benches.

- Research Laboratories: Useful for experimental setups requiring encoder feedback and stable rotation.

- Industrial Automation: Supports rotational motion control in manufacturing and inspection systems.

- Metrology and Calibration: Provides high accuracy for calibration of angular measurement devices.

Frequently Asked Questions

What is the X-RSW-E Series product?

What is the maximum speed and torque of the X-RSW-E Series product?

Can multiple X-Series products use a single power supply?

What is the encoder resolution of the X-RSW-E Series product?

What power supply is required for the X-RSW-E Series product?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle