Description

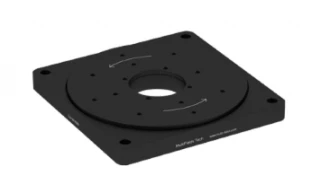

Zaber's X-RSB-E Series rotation stages are expertly engineered to deliver exceptional performance in motion control applications. These stages boast a 120 mm table diameter and a 50.8 mm (2 inch) aperture, making them compact yet powerful. Their low profile and robust construction allow them to support loads of up to 50 kg, ensuring versatility in a variety of settings. With a maximum speed of 300 rpm, these stages are perfect for the rapid and precise positioning of light loads, achieving accuracy to within a fraction of a degree.

Designed as stand-alone units, the X-RSB-E Series requires only a standard 24 V or 48 V power supply. The integration of a built-in motor encoder facilitates closed-loop operation, complete with slip/stall recovery features for enhanced reliability. Users can select between two motor configurations: motor up, which allows flush mounting to a flat surface, and motor down, which supports full 360° movement for loads extending beyond the stage top. The inclusion of an indexed knob provides manual control, offering flexibility even without computer assistance.

Connectivity is a key feature of the X-RSB-E Series, as these stages can be easily connected to the RS-232 or USB port of any computer. They also support daisy-chaining with other Zaber products, enabling multiple X-Series devices to share a single power supply through the shared power feature. The secure connection is ensured by convenient locking, 4-pin, M8 connectors. True to Zaber's commitment to user-friendly designs, the X-RSB-E Series stages are 'plug and play', making setup and operation straightforward and hassle-free.

Motorized Rotation Stage X-RSB120AD-E01

Specifications

| Vacuum Compatible: | Yes |

|---|---|

| Built-in Controller: | Yes |

| Range: | 360 degrees |

| Unidirectional Accuracy: | 0.19 degrees |

| Repeatability: | <0.5 degrees |

| Backlash: | 0.19 degrees |

| Encoder Resolution: | 500 CPR |

| Stage Diameter: | 120 mm |

Features

- Continuous 360° Rotation Stage: Enables full circular motion for versatile applications.

- High-Speed Performance: Achieves speeds up to 300 rpm, ideal for rapid positioning.

- 50.8 mm Aperture: Allows for significant load handling and flexibility.

- Built-in Controller: Integrates easily with other Zaber products through daisy-chaining.

- Multiple Motor Configurations: Offers both 'motor up' for flush mounting and 'motor down' for extended load movement.

- Encoder Position Feedback: Features slip/stall detection and automatic recovery for reliable operation.

- Compact and Sturdy Design: 120 mm table diameter with a low profile and a load capacity of up to 50 kg.

- Plug and Play Setup: Easy to set up and operate with RS-232 or USB connectivity.

- Manual Control Option: Indexed knob for convenient operation without a computer.

- Power Sharing Capability: Daisy-chain power sharing with other X-Series products using a single power supply.

- Secure Connections: Locking 4-pin M8 connectors ensure stable unit connections.

- High Precision: Microstep size of 0.005625° and repeatability of < 0.02°.

- Robust Communication Interface: Supports RS-232 with Zaber ASCII and Binary protocols.

- Durable Load Handling: Maximum centered load of 500 N and cantilever load of 2000 N•cm.

- Energy Efficient: Operates with a power supply of 24 - 48 VDC and a maximum current draw of 1200 mA.

Applications

- Precision Optical Systems: Ideal for rotating optical components with high accuracy.

- Metrology and Inspection: Provides rapid and precise rotational positioning in measurement setups.

- Automated Assembly Systems: Enhances flexibility in robotic or assembly line integration.

- Research and Development: Supports experimental setups requiring programmable rotation.

- Laser Alignment Systems: Facilitates accurate beam alignment with rotational control.

Frequently Asked Questions

What is the load capability of the X-RSB-E Series rotation stages?

What power supply is required for the X-RSB-E Series rotation stages?

What motor configurations are available for the X-RSB-E Series rotation stages?

Can the X-RSB-E Series rotation stages be controlled manually?

Can the X-RSB-E Series rotation stages be connected to other Zaber products?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle