Description

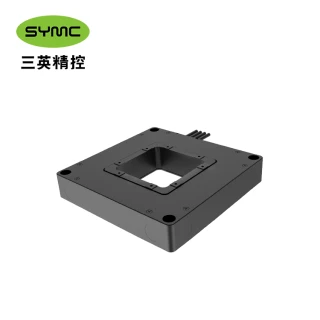

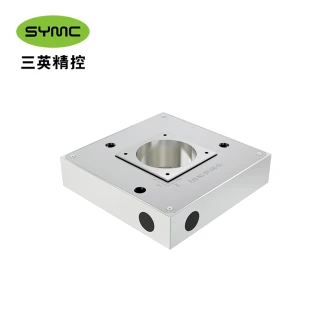

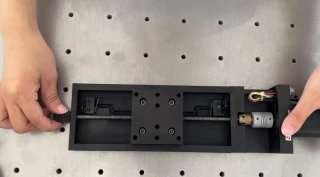

The Scanner25-z is a compact, high-performance piezoelectric motion scanner designed for use in demanding low-temperature and high-vacuum environments. With dimensions of 25 x 25 x 8.5 mm, this scanner provides a high load capacity of up to 200g while maintaining precise control and positioning. It is compatible with ultra-high vacuum (UHV) conditions (down to 2E-11 mbar) and operates at temperatures as low as 30 mK, making it ideal for cryogenic and scientific research.

Crafted from non-magnetic materials such as pure titanium (Ti) and beryllium copper (BeCu), the Scanner25-z is resilient in magnetic fields up to 18 Tesla, allowing for integration into high-field experiments. The device offers a travel range of 55 µm at 300 K and provides high-resolution position sensing down to 0.8 nm. It is available in various configurations, including HV, ULT, and UHV versions, to cater to specific experimental needs.

The Scanner25-z is perfect for applications requiring precise motion control in extreme environments, ensuring accuracy and reliability in a wide range of scientific disciplines.

Compact High-Load Scanner25-z: Low Temperature Piezoelectric Motion with Ultra-High Vacuum Compatibility

Specifications

| Axes Of Motion: | One |

|---|---|

| Travel Range: | 0.055 mm |

| Load Capacity (Horizontal): | 0.2 kg |

| Load Capacity (Vertical): | Not Specified |

| Max Speed: | Not Specified |

| Weight: | 0.02 kg |

| Guiding Mechanism: | Other |

| Voltage Requirement: | Other |

| Capacitance @300 K: | 4.2 uF |

| Resolution: | 0.8 nm |

| Linearity Error: | Typical ~ 0.1 % |

| Dimensions (WxHxD): | 25 x 25 x 8.5 mm |

| Temperature Range: | 1.4 to 400 K |

| Vacuum Compatibility: | 2E-7 mbar (UHV version: 2E-11 mbar) |

| Max Magnetic Field: | 18 Tesla |

| Drive Voltage Max: | 75 V @300 K, Max 180 V @4 K |

| Materials (Main Body): | Pure Ti, BeCu |

Features

- Compact Design: Small footprint (25 x 25 x 8.5 mm) for use in space-constrained setups

- Ultra-Low Temperature and Vacuum Compatibility: Operates in environments down to 30 mK and vacuum pressures as low as 2E-11 mbar

- Non-Magnetic Construction: Made from pure titanium (Ti) and beryllium copper (BeCu) for compatibility with 18 Tesla magnetic fields

- High Load Capacity: Can support up to 200 g, making it suitable for demanding applications

- Large Travel Range: 55 µm at 300 K for versatile motion

- High Resolution: Position sensing with a precision of up to 0.8 nm

- Multiple Versions Available: HV, ULT, and UHV versions for different experimental needs

- Low Capacitance: 4.2 µF at 300 K ensures efficient operation in low-temperature environments

Applications

- Cryogenic Research: Ideal for use in He3 and dilution cryogenics systems due to its low temperature capability (30 mK)

- High-Vacuum Studies: Compatible with ultra-high vacuum conditions, suitable for experiments requiring pressures as low as 2E-11 mbar

- Magnetic Field Research: Works in magnetic environments up to 18 Tesla, making it suitable for high-field experiments

- Precision Motion Control: Excellent for applications requiring precise, high-resolution movement (0.8 nm resolution)

- Nanotechnology: Perfect for precision manipulation of components at the nanoscale

Frequently Asked Questions

What are the dimensions and weight of the Scanner25-z?

Is the Scanner25-z suitable for ultra-high vacuum and very low temperature?

Can the Scanner25-z operate in high magnetic fields?

What is the travel range and resolution of the Scanner25-z?

What load capacity does the Scanner25-z support?

What are the ideal applications of the Scanner25-z?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle