Description

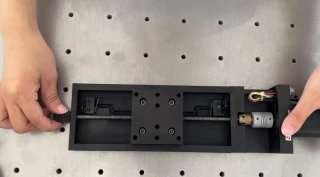

The PAxx-Z Series precise motorized vertical-motion stages are highly versatile, high-precision positioning systems designed specifically for fine vertical (Z-direction) adjustments. Based on the well-established PA-11-X motorized linear stages by Zolix, the PAxx-Z series incorporates a right-angle fixing block and a power-failure protection unit, ensuring enhanced stability and reliability during operations.

These stages offer a range of models from PA050-Z to PA1000-Z, each catering to different travel ranges (50 mm to 1000 mm) and load capacities (up to 30 kg). Featuring high-precision ball screws and linear-slider guides, they provide smooth motion with a maximum speed of 50 mm/s.

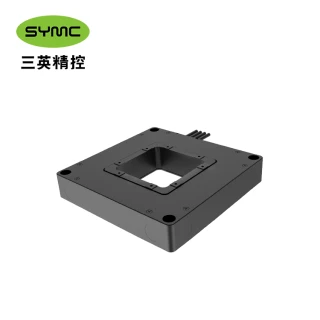

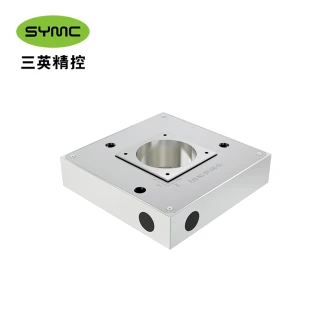

Built from black anodic-oxidized aluminum alloy, the PAxx-Z stages are designed for durability and long-lasting performance, even in challenging environments. With a resolution ranging from 1 to 25 µm and high accuracy in repositioning, these stages are ideal for applications where fine vertical motion and precise alignment are crucial, such as in optics, research, automation, and 3D alignment systems.

Whether for laboratory testing or industrial automation, these stages offer exceptional versatility, accuracy, and speed for precise vertical motion control.

PA050-Z Precise Motorized Vertical-Motion Stage

Specifications

| Axes Of Motion: | One |

|---|---|

| Travel Range: | 50 mm |

| Load Capacity (Horizontal): | Not Specified |

| Load Capacity (Vertical): | 15 kg |

| Max Speed: | 40 mm/s |

| Weight: | 7.6 kg |

| Guiding Mechanism: | High-Precision Profiled Rails |

| Voltage Requirement: | DC 24V |

| Consuming Current: | <60 mA |

| Length Of Cables For Stages: | 0.2 m |

| Torque Of Motor: | 1.3 N·m |

| Working Current: | 2.0 A |

| Motor And Its Stepping Angle (°): | Two-phase 57 stepping motor, 1.8 |

| Motion Linearity: | ≤10 µm |

| Backlash Clearance: | Backlash clearance µm |

| Repositioning Accuracy: | ≤±3 µm |

| Single-direction Positioning Accuracy: | ≤30 µm |

| Main Body Materials And Surface Treatments: | Black anodic-oxidation aluminum-alloy |

| Guides (Guiding Mechanism): | Linear-slider guides |

| Table Dimensions: | 120x120 mm |

| 20-fine-subdivision Resolution: | 1 µm |

Features

- High Precision: Resolution of 1 to 25 µm, with fine subdivision accuracy

- Versatile Models: Travel range from 50 mm to 1000 mm, suitable for various applications

- High Load Capacity: Capable of handling vertical loads up to 30 kg

- Durable Construction: Black anodic-oxidized aluminum-alloy body for long-lasting performance

- High Speed: Maximum speed of up to 50 mm/s depending on model

- Built-in Sensors: Includes position-limit and origin-point sensors for accurate control

- Easy Integration: DB9 pin connectors and flexible cables ensure smooth installation

Applications

- Precision Vertical Positioning: Ideal for applications requiring fine vertical motion adjustments in laboratory settings

- Research and Development: Used in research environments, including optics, material science, and microscopy

- Automation Systems: Suitable for precision automation in manufacturing and testing

- 3D Alignment Systems: Can be integrated into 2D or 3D motorized alignment setups for complex positioning tasks

Frequently Asked Questions

What is the PAxx-Z series precise motorized vertical-motion stage used for?

What are the mechanical specifications of the PAxx-Z series stages?

What are the accuracy specifications of the PAxx-Z series stages?

What are the electrical specifications of the PAxx-Z series stages?

What are the dimensions of the PAxx-Z series stages?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle