Description

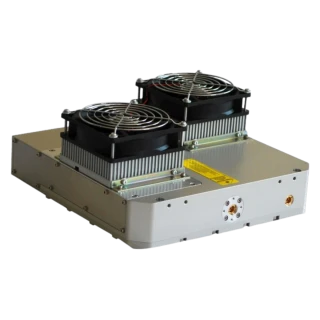

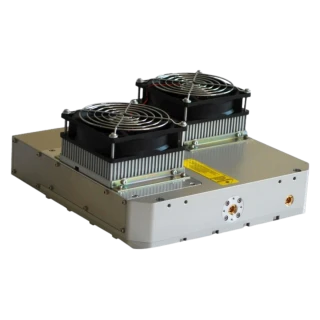

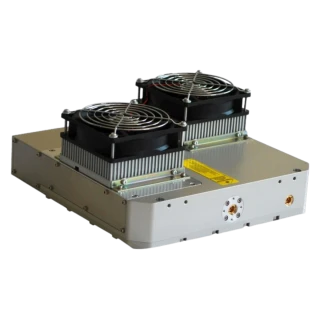

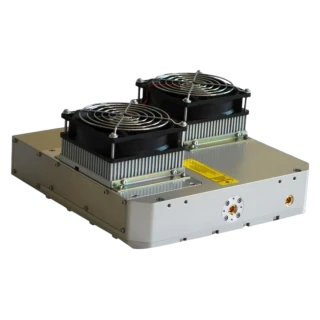

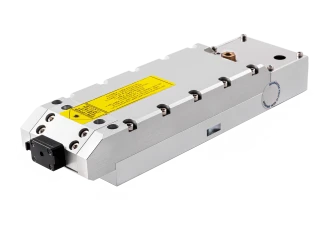

The RX IR/Green/UV Series Low Power Picosecond Lasers represent a significant advancement in laser technology, offering a compact and high-performance solution for a variety of industrial applications. With a patented pulse selection system and a track record of over a thousand units shipped globally, the RX Series stands out with its revolutionary packaging that surpasses the capabilities of its predecessor, the RGH series. This series delivers impressive output powers ranging from 10W to 100W for IR, 5W to 70W for Green, and 3W to 45W for UV, all within a streamlined All-in-One (AIO) platform that supports operations from single shot to 2MHz, with an optional upgrade to 8MHz.

The RX Series lasers leverage proprietary technologies to deliver pulse energies that are twice as high as those of comparable systems from competitors. This enhancement in pulse energy facilitates process efficiency optimization through spatial scaling, allowing the laser beam to be split multiple times to serve several workstations simultaneously. This capability significantly reduces the Cost of Ownership (COO), making the RX Series an economically attractive option for businesses looking to maximize productivity.

Designed with user convenience in mind, the RX Series features a user-friendly control interface that offers Total Pulse Control and Burst Mode operation. Users can select up to 10 picosecond pulses with adjustable 14 ns incremental separation and programmable amplitude, enabling increased ablation rates on various materials. The adjustable repetition rate, ranging from single shot to 8MHz, allows users to dynamically alter the operating PRF and adjust power or pulse energy via the PEC (Power or Pulse Energy Control) function, ensuring maximum process flexibility.

Photonics Industries' picosecond lasers have demonstrated exceptional robustness, even in the most demanding industrial manufacturing environments. This makes them ideal for a wide range of applications, including metal engraving and marking, LED dicing, thin film removal, small feature structuring, and cutting and drilling of materials such as glass, sapphire, and ceramics. Additionally, they are well-suited for advanced applications like 3D LIDAR, showcasing their versatility and reliability in cutting-edge technological fields.

RX Series Low Power Picosecond Lasers

Specifications

| Avg. Power: | 3 W |

|---|---|

| Wavelength: | 355 nm |

| Repetition Rate: | 0.001 – 8000 kHz |

| Spatial Mode (M^2): | 1.2 |

| Pulse Duration: | 0.007 ns |

| Pulse-to-Pulse Stability (RMS): | 1 % |

| Cooling: | Water-to-Water, Water-to-Air |

Features

- Short Pulse Duration: Less than 10 ps for IR, approximately 7 ps for Green and UV lasers.

- Wide Range of Wavelengths: Available in 1064 nm, 532 nm, and 355 nm, with 266 nm available upon request.

- Compact and Rugged Design: The most compact, All-in-One form factor for ease of integration.

- High Efficiency: The highest efficiency picosecond laser with typical power consumption under 400 W.

- Variable Repetition Rates: From single shot up to 8 MHz for versatile applications.

- Excellent Beam Quality: TEM00 beam with typical M2 ≤ 1.2 for precision work.

- Exceptional Beam Pointing Stability: Less than 20 μrad for consistent performance.

- Power or Pulse Energy Control (PEC): Allows on-the-fly adjustments to maximize process flexibility.

- Position Synchronized Output (PSO): Supports external triggering to any arbitrary PRF while maintaining stable pulse energy with low jitter.

- Burst Mode: Individually controllable bursts of up to 10 pulses with a separation of 14 ns for enhanced material processing.

- Pulse-On-Demand (POD): Enables bursts of pulses with separation equal to the PRF, triggered internally, externally, or continuously, while maintaining constant pulse energy.

Applications

- Display Manufacturing: Cutting/scribing display glass and functional foils.

- Semiconductor Industry: Wafer scribing, dicing, and thin-film removal.

- LED Fabrication: Scribing, dicing, and patterning.

- Medical Devices: Precision cutting, drilling, and marking.

- Glass & Ceramics: Cutting, drilling, and structuring sapphire, ceramics, and reinforced glass.

- PCB & Solar Cells: Micromachining, scribing, and drilling for electronics and photovoltaics.

- Advanced Materials: Nanotexturing, carbon fiber cutting, ink-jet nozzle drilling.

3D Sensing: Ideal for LiDAR and next-gen optical applications.

Frequently Asked Questions

What is the power range of the RX Series Low Power Picosecond Lasers?

What is the repetition rate of the RX Series lasers?

What are the applications of the RX Series lasers?

What are the features of the RX Series lasers?

How does the RX Series lasers compare to competitors' systems?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle