Description

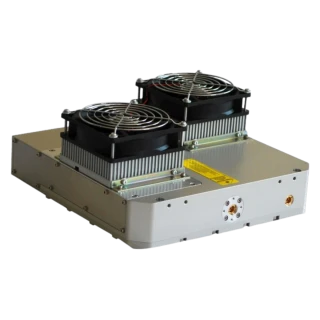

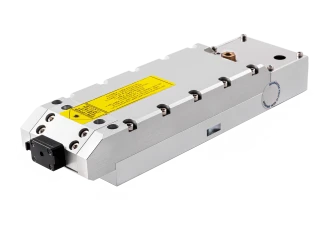

The Rigel i600 by Powerlase Photonics is a cutting-edge 600-watt Q-switched, diode-pumped solid-state (DPSS) laser. Operating at a wavelength of 1064 nm, this laser delivers both high average power and peak power, making it an exceptional choice for demanding industrial applications. Its unpolarised beam and robust design ensure reliable performance, even in challenging environments.

Engineered with a rugged head design, the Rigel i600 is built to withstand the rigors of high-volume industrial use. The laser's state-of-the-art universal control system architecture allows for seamless integration and synchronization with OEM equipment and process lines. This adaptability makes the Rigel i600 a versatile tool that can be tailored to meet the specific needs of various industrial processes.

The Rigel i600 is not just about power; it also offers precision and stability. With excellent power stability and optional features like fiber delivery and computer-controlled attenuation, this laser provides users with the flexibility and control needed for precise material processing. Its condition monitoring capabilities further enhance reliability, ensuring consistent performance and reducing downtime.

Designed to operate efficiently within a range of environmental conditions, the Rigel i600 requires minimal facility requirements, making it a practical choice for a wide range of industrial settings. Whether you are involved in material processing, photovoltaic processing, thin film removal, or rapid laser patterning, the Rigel i600 offers the performance and reliability you need to achieve optimal results.

Rigel i600 Q-Switched DPSS Laser for Industrial Applications

Specifications

| Avg. Power: | 600 W |

|---|---|

| Wavelength: | 1064 nm |

| Repetition Rate: | 5 – 15 kHz |

| Spatial Mode (M^2): | 22 |

| Pulse Duration: | 30 ns |

| Pulse-to-Pulse Stability (RMS): | 1 % |

| Cooling: | Water-to-Water |

| Pulse Energy: | Up To 90 mJ |

| Divergence: | 10 mrad |

| Power Stability: | 0.3% |

| Typical Fibre Core: | 600 μm |

| Supply Voltage: | 3-phase N+E, 220 or 400 VAC (±10%) |

| Supply Frequency: | 50 or 60 Hz |

| Nominal Power Consumption: | 15 kVA |

| Gas Purge: | N2 or Air (Grade N5.0, <1 ppm THC) |

| Laser Dimensions: | 1800 x 560 x 320 mm |

| Control Rack Dimensions: | 1195 x 600 x 970 mm |

| Environmental Conditions: | Temp 15 - 32°C and RH <60% (90% max, non condensing) |

Features

- High Power Output: The Rigel i600 delivers a powerful 600 watts of average power, making it ideal for demanding industrial applications.

- Q-Switched, DPSS Laser: Offers high peak power at 1064 nm, unpolarized, suitable for various processing needs.

- Rugged Design: Features a well-proven, robust head design that ensures durability and reliability in high-volume operations.

- Universal Control System: State-of-the-art architecture allows for simple synchronization with OEM equipment and process lines.

- Excellent Stability: Provides consistent performance with a power stability of 0.3% (1σ).

- Condition Monitoring: Integrated systems to monitor and maintain optimal laser conditions.

Applications

- Material Processing: Ideal for high volume industrial applications, the Rigel i600 is designed to handle various material processing tasks efficiently.

- Photovoltaic Processing: This laser is perfect for applications in the photovoltaic industry, ensuring precision and speed in processing solar cells.

- Thin Film Removal: The Rigel i600 excels in removing thin films with high accuracy, making it suitable for delicate and detailed tasks.

- Rapid Laser Patterning: With its high power and precision, the Rigel i600 enables rapid patterning on various surfaces, enhancing productivity in manufacturing processes.

Frequently Asked Questions

What is the maximum pulse energy of the Rigel i600 DPSS laser?

What is the typical fibre core size for the Rigel i600 DPSS laser?

What are the dimensions of the Rigel i600 DPSS laser?

What is the power stability of the Rigel i600 DPSS laser?

What are some applications of the Rigel i600 DPSS laser?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle