Description

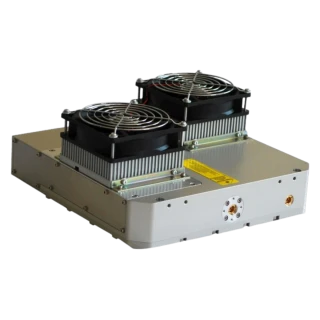

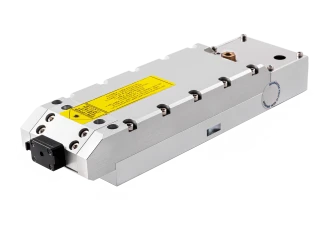

The DMX YAG Green Series lasers from Photonix represent a breakthrough in laser technology, offering a unique combination of simplicity and efficiency in a monolithic platform. These diode-pumped lasers are designed with intra-cavity patented technologies that enable them to deliver high power at 532 nm, reaching up to 200W from a single head and up to 400W when configured as a dual head. This remarkable power output is achieved at kHz repetition rates, making these lasers an ideal choice for demanding applications.

One of the standout features of the DMX YAG Green Series is its exceptional thermal management system. This allows users to adjust the repetition rate from 1 to 30 kHz on lower power models and from 1 to 50 kHz on higher power models, providing flexibility and control over laser performance. The single head models are equipped with a dual pulse feature, supported by proprietary driving electronics that manage pulse separation and delay. For applications requiring even higher output powers and sub-microsecond pulse separations, the lasers can be configured in a dual head option.

The DMX YAG Green Series is engineered for high repetition rate pumping of Ti:sapphire laser amplifiers and Particle Image Velocimetry (PIV) applications. Its compact form factor and integrated controls within the laser head ensure ease of use and operability via GUI software. The laser's design includes a uniform beam profile and superior pulse-to-pulse stability, making it a reliable and efficient tool for a variety of scientific and industrial applications. With its innovative features and robust performance, the DMX YAG Green Series stands out as a leader in laser technology.

DMX Series High Power Nanosecond Lasers

Specifications

| Avg. Power: | 60 W |

|---|---|

| Wavelength: | 532 nm |

| Repetition Rate: | 1 – 50 kHz |

| Spatial Mode (M^2): | 15 |

| Pulse Duration: | 120 ns |

| Pulse-to-Pulse Stability (RMS): | 1 % |

| Cooling: | Water-to-Water, Water-to-Air |

Features

- High Power Output: Achieve up to 200W from a single head and up to 400W from a dual head at 532 nm, ideal for high repetition rate applications.

- Compact and Efficient Design: Features a monolithic platform with integrated controls within the laser head for ease of use via GUI software.

- Flexible Repetition Rates: Adjustable from 1 to 30 kHz for lower power models and 1 to 50 kHz for higher power models, catering to various application needs.

- Proprietary Twin Pulse Option: Offers a unique twin pulse mode for enhanced performance, with user-programmable energy ratio and pulse separation.

- Dual Head Configuration: Available for even higher output powers and sub-microsecond pulse separations, with GUI software adjustable turning mirrors.

- Uniform Beam Profile: Ensures superior pulse-to-pulse stability and consistent performance across applications.

- Robust Applications: Suitable for Particle Image Velocimetry (PIV), annealing, pumping Ti:Sa ultrafast amplifier systems, and high power drilling or cutting of hard materials.

- Optimized Power Supply: Ideally sized for 19” rack-mount configurations, with an optional flange kit available.

- Superior Stability: Offers pulse-to-pulse stability of < 1.0% rms and long-term stability of < 0.5% rms.

- Advanced Beam Characteristics: Horizontal polarization with a 100:1 ratio, nominal beam diameters of 2.0 mm and 5.0 mm, and beam circularity > 85%.

- Versatile Interface Options: Includes RS 232, external TTL triggering, and GUI software for seamless integration and control.

Applications

- Particle Image Velocimetry (PIV): High-power pulsed illumination for fluid dynamics research.

- Ti:Sapphire Amplifier Pumping: Reliable excitation for ultrafast laser systems.

- Material Annealing / Bleaching: Modify material properties without ablation.

- High-Energy Drilling & Cutting: Precision processing of hard and brittle materials.

Frequently Asked Questions

What is the power range of the DMX Series High Power Nanosecond Lasers?

Can the repetition rate be adjusted on these lasers?

What are the applications for the DMX Series High Power Nanosecond Lasers?

Is there a dual head option available for these lasers?

What is the advantage of the proprietary twin pulse mode?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle