Description

Suzhou Delphi Laser Co., Ltd. (苏州德龙激光有限公司) is proud to present the P302 Picosecond Laser, a cutting-edge solution designed to meet the demands of modern industrial and scientific applications. Located in the heart of Suzhou, China, our company is dedicated to delivering high-quality laser technologies that combine innovation with reliability.

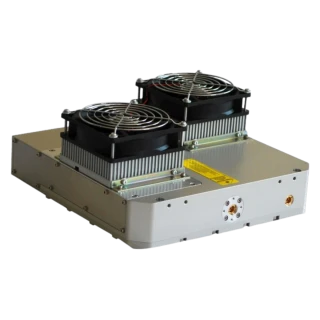

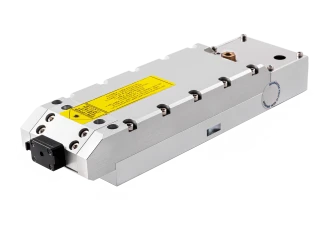

The P302 Picosecond Laser represents a significant advancement in laser technology, merging the benefits of a free-space solid-state amplifier with the versatility of fiber laser technology. This combination results in a laser system that offers excellent beam divergence and extremely narrow pulse widths, all while maintaining high power outputs. The integration of a fiber seed enhances the stability and compactness of the laser, making it more operationally flexible compared to traditional solid-state seed lasers.

One of the standout features of the P302 is its solid-state amplifier, which allows for the delivery of high pulse energies without compromising on beam quality. This results in superior processing capabilities, characterized by smaller heat-affected zones and precision results. The laser's pulse widths are in the low picosecond range, enabling exceptional performance in various applications. Additionally, the adjustable pulse repetition rate from 50 to 500 kHz provides users with the flexibility to tailor the laser's output to specific needs.

Suzhou Delphi Laser Co., Ltd. is committed to providing laser solutions that not only meet but exceed industry standards. The P302 Picosecond Laser is a testament to our dedication to innovation, quality, and customer satisfaction.

10W Picosecond DPSS Laser Source

Specifications

| Avg. Power: | 10 W |

|---|---|

| Wavelength: | 1064 nm |

| Repetition Rate: | 50 – 500 kHz |

| Spatial Mode (M^2): | 1.3 |

| Pulse Duration: | 0.015 ns |

| Pulse-to-Pulse Stability (RMS): | 3 % |

| Cooling: | Water-to-Water |

| Model Number: | P302 |

Features

- Advanced Laser Technology: The P302 Picosecond Laser combines an advanced free-space solid state amplifier with fiber laser technology for superior performance.

- High Power Output: Achieves average power of over 10W at 500kHz, suitable for demanding applications.

- Adjustable Pulse Repetition Rate: Offers flexibility with a pulse repetition rate adjustable from 50 to 500 kHz.

- Excellent Beam Quality: Features a TEM00 spatial mode with M2 <1.3, ensuring high-quality beam output.

- Ultra-Short Pulse Width: Delivers pulse widths of less than 15 picoseconds for precise processing with minimal heat-affected zones.

- Burst Mode: Includes a burst mode for enhanced operational capabilities.

- Compact and Stable Design: Compact design with high long-term stability, making it suitable for various industrial environments.

- Control Options: Equipped with RS232 and external GATE control for easy integration into existing systems.

- Field-Replaceable Laser Diode Module: Simplifies maintenance and reduces downtime.

- Wide Range of Applications: Ideal for material micromachining, glass cutting and drilling, wafer dicing, sapphire cutting and drilling, thin film cutting, and scientific research.

- Precision and Stability: Features <3% rms pulse-to-pulse instability and <3% rms average power stability over 8 hours.

- Efficient Cooling: Water-cooling system ensures optimal performance and longevity.

- Environmental Adaptability: Operates in ambient temperatures of 15 – 30℃ and can be stored between -10 – 50℃.

- Quick Start-Up: Warm-up time is less than 10 minutes, allowing for rapid deployment.

- Versatile Voltage Range: Operates on a wide voltage range of 90 – 260V, accommodating various power supplies.

Applications

- Material Micromachining: Enables precise microfabrication with minimal thermal damage.

- Glass Cutting and Drilling: Ideal for processing brittle and transparent materials with high accuracy.

- Wafer Dicing: Provides clean and precise dicing of semiconductor wafers.

- Sapphire Cutting and Drilling: Supports advanced processing of hard crystalline materials.

- Thin Film Cutting: Ensures precise separation of delicate thin film layers.

- Scientific Research: Suitable for ultrafast laser experiments and advanced material studies.

Frequently Asked Questions

What are some applications of the P302 laser?

What is the average power output of the P302 laser?

What is the pulse repetition rate range of the P302 laser?

What is the warm-up time for the P302 laser?

What is the pulse width of the P302 laser?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle