Description

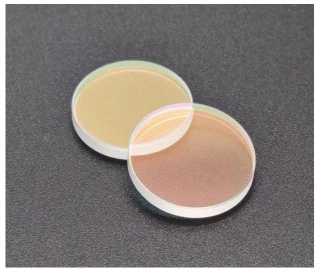

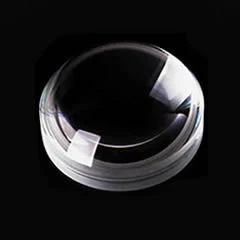

Zinc selenide is a commonly used optical glass material in the infrared band with a transmission band of 600nm-16μm. It has low absorption and thermal shock resistance, and is commonly used in thermal imaging systems, as well as in some visible optical systems, and can be used as a substrate for a variety of optical components. Zinc selenide (ZnSe) plano-convex (PCX) lenses are mainly used for focusing or collimating applications in the mid-wave and long-wave infrared spectra. ZnSe PCX lenses focus light into a single point and are commonly used for aiming and focusing monochromatic light sources.

UM Optics Custom Optical ZnSe Zinc Selenide Plano Convex Focusing Lens

Specifications

| Material: | ZnSe |

|---|---|

| Diameter: | 50.8 mm |

| Focal Length: | 150 mm |

| Edge Thickness, Te: | 2.5 mm |

| Lens Type: | Plano-Convex |

| Diameter Tolerance: | +0/-0.1mm |

| Thickness Tolerance: | ±0.1mm |

| Surface Quality: | 60-40 Scratch-dig |

| Surface Accuracy: | 1/4 lambda |

Features

- High transmittance: ZnSe offers excellent transmission in the mid-infrared range

- Low absorption: Minimal energy loss makes it suitable for high-power laser systems.

- Thermal stability: Maintains performance under high-temperature conditions.

- Durable coating compatibility: Supports anti-reflective or protective coatings for enhanced efficiency.

Applications

- CO2 laser systems: Widely used for focusing and directing high-power infrared laser beams.

- Thermal imaging: Enhances resolution in infrared cameras and sensors.

- Spectroscopy: Facilitates precise light focusing in gas analysis or material characterization.

- Medical devices: Applied in laser surgery or dermatology for targeted energy delivery.

- Industrial processing: Enables precision cutting, welding, and engraving in manufacturing.

Frequently Asked Questions

What makes ZnSe a preferred material for focusing lens in mid-infrared applications?

ZnSe offers high transmittance (>70%) in the mid-infrared range (8–12 μm), making it ideal for systems like CO₂ lasers and thermal imaging.

How does ZnSe compare to germanium (Ge) or silicon (Si) in laser applications?

Unlike Ge or Si, ZnSe has lower absorption and better thermal stability under high-power laser exposure, reducing thermal lensing effects.

What coatings are recommended for ZnSe lens in thermal imaging systems?

For 3–5 μm or 8–12 μm thermal imaging bands, we apply broadband anti-reflective (AR) coatings that reduce surface reflections to

Can UM Optics customize znse plano convex lens for high-volume industrial laser systems?

Yes. As a factory, we support mass production of standard or custom ZnSe plano convex lens for laser equipment manufacturers. We offer automated polishing and quality control to ensure batch consistency, with competitive pricing for large orders.

Similar Products

High Precision MgF2 Optical Dome Magnesium Fluoride Ball Dome for IR Imaging Systems

Henan UM Optics Ltd

Customizable Spherical Lenses

CRYSTECH Inc.

10mm Sapphire Convex Lens with Anti-Reflection (AR) Coating – 3mm Thickness

Henyuan Sapphire Optics Co., Ltd.

40mm Sapphire Concave Lens with Anti-Reflection (AR) Coating – 8mm Thickness

Henyuan Sapphire Optics Co., Ltd.

15mm Sapphire Lens with Anti-Reflection (AR) Coating – 3mm Thickness

Henyuan Sapphire Optics Co., Ltd.

Sapphire Ball Lens 8.6mm Ø

Henyuan Sapphire Optics Co., Ltd.

AR-Coating Sapphire Ball Lens 48mm Diameter

Henyuan Sapphire Optics Co., Ltd.

Precision Spherical Lenses | Convex, Concave & Meniscus Optics

Langjie-optics Inc

High-Precision Micro Lens for Advanced Optical Applications

Sinoptix

Custom Glass Domes for Advanced Optical Applications

Sinoptix

Customizable TPX Lens for Terahertz and Cryogenic Devices

Sinoptix

Optical Fused Silica Quartz Glass Collimating Lens

Henan UM Optics Ltd

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle