Description

art photonics’ Copper-alloy Coated Silica Fibers are the optimal solution for applications in high temperature, vacuum and harsh environment conditions. Cu-alloy coated fibers have all benefits of silica fibers. Additional significant advantages include a superior mechanical strength and better fatigue resistance compared to polymer coated fibers.

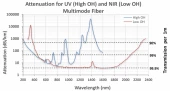

The transmission range spans 220 to 2400 nm depending on UV or NIR silica fiber core choice. The working temperature range is from -270°C to 600°C; humidity – up to 100%.

Metal-coated Silica Fibers: Step Index, 9/125, Cu-alloy Coated

Specifications

| Core Diameter: | 9 um |

|---|---|

| Wavelength Range: | 180 – 2400 nm |

| Cable Length: | Not Specified |

| Fiber Core Material: | Silica |

| Coating Material: | Copper-alloy |

| Core Diameter: | 9 µm |

| Cladding: | 125 ± 2% µm |

| Coating Thickness: | 165 ± 2% µm |

| Available Fiber Core Diameters: | 9, 50, 100, 200, 400, 600 µm |

Features

- Core/Cladding material: Pure Fused Silica Core/Fluorine Doped Silica Cladding

- High OH- ( λ= 0.22 – 1.2 μm)

- Low OH- ( λ= 0.35 – 2.5 μm)

- Numerical Aperture (NA): 0.12 ± 0.02 (Full Acceptance Angle 14°)

- Material of metal coating: Cu-alloy (Al is available)

- Humidity Range: Up to 100%

- Minimal bending radius (long term): 200 x fiber outer diameter

- Minimal bending radius (short term): 100 x fiber outer diameter

- Coating material: Copper-alloy

- Min operating temperature: -270°C

- Max operating temperature: 600°C

- Tensile strength (short gauge): 3.5–6 GPa

- Two point bending strength: >10GPa

- Static fatigue parameter: >100

Applications

- High temperature environments

- Harsh chemical environments

- Nuclear radiation resistant devices

- High power laser delivery

- Down-hole sensing for oil and gas industry

- Medical applications

- Soldered fiber bundles

Frequently Asked Questions

What are Metal Coated Fibers?

Metal Coated Fibers are silica fibers coated with metal, such as aluminum or copper, that are designed for use in high temperature, vacuum, and harsh chemical environments.

What is the core material of Metal Coated Fibers?

The core material of Metal Coated Fibers is pure silica, with high or low OH- depending on the wavelength range.

What is the numerical aperture of Metal Coated Fibers?

The standard numerical aperture of Metal Coated Fibers is 0.22 ± 0.02, with available numerical apertures of 0.12 ± 0.02 and 0.26 ± 0.02.

What is the temperature range for Metal Coated Fibers?

Metal Coated Fibers can operate in temperatures ranging from -270°C to 400°C for Al and up to 600°C for Cu-alloy.

What are some applications of Metal Coated Fibers?

Metal Coated Fibers are used in high temperature environments, harsh chemical environments, nuclear radiation, high power laser delivery, medical applications, and soldered fiber bundles.

Similar Products

Optical Fiber Series

Evolve Sensing

Copper-Alloy Coated Silica Fibers for Extreme Conditions

MiR Photonics LLC

Aluminum Coated Silica Fibers for Extreme Conditions and High Temperatures

MiR Photonics LLC

PSHC 200/230 Low OH Fiber for Laser and LED Applications

j-fiber GmbH

j-fiber Multimode HPSC Optical Fiber for High Power Laser Transmission

j-fiber GmbH

Step-index Fiber 190/200/245 High NA Ge-doped Low-OH

j-fiber GmbH

MIL-Spec Radiation Hard Multimode Fiber 62.5/125/245µm

j-fiber GmbH

62.5/125 Radiation Hard Multimode Fiber for Military and Aerospace

j-fiber GmbH

MIL-Spec Radiation Hard Multimode Fiber 62.5/125/500µm

j-fiber GmbH

j-fiber 100/140µm & 100/125µm Graded Index Multimode Fiber

j-fiber GmbH

j-BendAble OM3 HTC High-Temperature Bend-Insensitive Fiber

j-fiber GmbH

BIMMF 50/125 Multimode Fiber for Sensing Applications

j-fiber GmbH

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle