Description

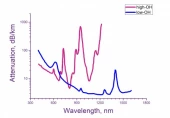

Hermetically sealed Aluminum-coated step index multimode optical fibers have all the benefits of silica-silica fibers. Additional significant improvements include increased mechanical strength and greater fatigue resistance compared to non-hermetic and polymer-clad fibers (PCS). Their transmittance covers a spectral range of 400 to 2200 nm, and also remains stable in corrosive chemicals that normally react to silica glass. The temperature range is from -196oC to +400oC. Hermetically metal-coated optical fibers are the optimum candidate when used in high vacuum and harsh environmental conditions

LOW OH MULTI-MODE STEP INDEX ALUMINUM-COATED SILICA FIBERS

Specifications

| Core Diameter: | Not Specified |

|---|---|

| Wavelength Range: | 400 – 2200 nm |

| Cable Length: | Not Specified |

| Fiber Core Material: | Silica |

| Coating Material: | Aluminium |

| Clad Material: | doped silica |

| Standard Core/Clad Diameters, µm (low OH): | 100/110, 150/165, 200/220, 300/330, 400/440, 600/636, 600/660, 800/848, 800/880, 1000/1060, 1000/1100 |

Features

- Greatly enhanced resistance to high power laser radiation.

- Higher core-to-clad ratio and enlarged NA optimized for coupling to high-energy lasers.

- Better fiber cooling due to the heat-conducting metal coating.

- Excellent mechanical strength and flexibility compared to polymer coated fibers.

- Capability to feed the fibers into a high vacuum: the metal coating can be soldered and will not outgas.

Frequently Asked Questions

What are the benefits of using hermetically sealed Aluminum-coated step index multimode optical fibers?

The benefits include increased mechanical strength, greater fatigue resistance, and stable transmittance in corrosive chemicals.

What is the temperature range that these fibers can withstand?

These fibers can withstand temperatures ranging from -196oC to +400oC.

What are the features of these Aluminum-coated fibers?

The features include enhanced resistance to high power laser radiation, optimized core-to-clad ratio for coupling to high-energy lasers, better fiber cooling, and excellent mechanical strength and flexibility.

Can the metal coating of these fibers be soldered?

Yes, the metal coating can be soldered and will not outgas.

What is the numerical aperture (NA) of these fibers?

The numerical aperture is 0.22 ± 0.02.

Similar Products

Optical Fiber Series

Evolve Sensing

Copper-Alloy Coated Silica Fibers for Extreme Conditions

MiR Photonics LLC

Aluminum Coated Silica Fibers for Extreme Conditions and High Temperatures

MiR Photonics LLC

PSHC 200/230 Low OH Fiber for Laser and LED Applications

j-fiber GmbH

j-fiber Multimode HPSC Optical Fiber for High Power Laser Transmission

j-fiber GmbH

Step-index Fiber 190/200/245 High NA Ge-doped Low-OH

j-fiber GmbH

MIL-Spec Radiation Hard Multimode Fiber 62.5/125/245µm

j-fiber GmbH

62.5/125 Radiation Hard Multimode Fiber for Military and Aerospace

j-fiber GmbH

MIL-Spec Radiation Hard Multimode Fiber 62.5/125/500µm

j-fiber GmbH

j-fiber 100/140µm & 100/125µm Graded Index Multimode Fiber

j-fiber GmbH

j-BendAble OM3 HTC High-Temperature Bend-Insensitive Fiber

j-fiber GmbH

BIMMF 50/125 Multimode Fiber for Sensing Applications

j-fiber GmbH

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle