Description

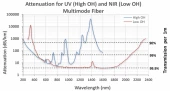

art photonics' Copper-alloy Coated Silica Fibers are engineered to deliver exceptional optical performance under extreme environmental conditions, making them an ideal choice for demanding industrial, medical, and scientific applications. These fibers combine the optical clarity and wide transmission range of silica fibers (220–2400 nm) with a mechanically robust copper-alloy coating that enhances thermal tolerance and resistance to fatigue.

Designed for use in high temperatures up to +600°C and cryogenic environments as low as –270°C, these fibers are also optimized for high humidity (up to 100%) and vacuum applications, offering zero outgassing performance. The durable metallic coating allows soldering without the need for epoxies, ensuring compatibility with high-vacuum systems and applications requiring sterilization, such as ETO, gamma, or e-beam processes.

Available in single-mode, graded-index, and step-index multimode configurations, these fibers offer flexible options for custom integration, from downhole sensing in the oil and gas industry to high-power laser delivery and medical diagnostics. With superior mechanical strength, high static fatigue resistance, and customizable numerical apertures, these fibers offer unmatched durability and precision in the harshest environments.

Metal-coated Silica Fibers: Multi-Mode, Cu-alloy Coated

Specifications

| Core Diameter: | 9 um |

|---|---|

| Wavelength Range: | 220 – 2400 nm |

| Cable Length: | 1 m |

| Fiber Core Material: | Silica |

| Available Fiber Core Diameters: | 9, 50, 100, 200, 400, 600 µm |

| Type: | Step / Graded Index |

| Coating Material: | Copper-alloy |

| Coating Thickness: | 15 - 50 µm |

| Operating Temperature Range: | –270 to +600 °C |

| Humidity Tolerance: | Up to 100% |

| Core/Cladding Material: | Pure/Fluorine Doped Silica (Step), Ge Doped Silica (Graded) |

| Coating Material: | Copper-Alloy |

| Numerical Aperture (Standard): | 0.22 ± 0.02 |

| Numerical Aperture (Custom): | 0.12 / 0.26 ± 0.02 |

| Long-Term Min. Bending Radius: | 200 × fiber OD µm |

| Short-Term Min. Bending Radius: | 100 × fiber OD µm |

| Tensile Strength: | 3.5 – 6 GPa |

| Two-Point Bending Strength: | >10 GPa |

| Static Fatigue Parameter: | >100 |

Features

- Wide Operating Temperature: From –270°C to +600°C in non-oxidizing atmospheres

- Excellent Mechanical Strength: High tensile and bending strength with long service life

- Vacuum Compatibility: No outgassing, ideal for ultra-clean and vacuum systems

- Solderable Interface: Epoxy-free integration into metal ferrules and connectors

- Sterilization Ready: ETO, steam, gamma, or e-beam sterilizable

- Heat Dissipation: Copper-alloy coating enables efficient thermal management

- Flexible NA Options: Standard NA 0.22, with custom variants from 0.12 to 0.26

Applications

- High-Temperature Environments: Suitable for aerospace, furnaces, and reactors

- Chemical & Radiation-Resistant Systems: Ideal for nuclear or corrosive settings

- Oil & Gas Exploration: Downhole sensing and harsh field conditions

- Medical Devices & Diagnostics: Use in sterilized environments or surgical tools

- High Power Laser Delivery: Secure and heat-tolerant optical channels

- Vacuum System Integration: For cleanroom and analytical instrumentation

- Soldered Fiber Assemblies: Durable configurations without adhesives

Frequently Asked Questions

What are Metal Coated Fibers?

What is the core material of Metal Coated Fibers?

What is the numerical aperture of Metal Coated Fibers?

What is the temperature range for Metal Coated Fibers?

What are some applications of Metal Coated Fibers?

What are the advantages of using Cu-alloy coated fibers compared to polymer coated fibers?

What is the transmission range of the Cu-alloy coated silica fibers?

What is the working temperature range of the Cu-alloy coated silica fibers?

What is the numerical aperture (NA) of the Cu-alloy coated silica fibers?

What are the applications of Cu-alloy coated silica fibers?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle