Description

The VFI Interferometric Inspection System stands as a pinnacle in precision optical inspection technology. This system is meticulously designed to evaluate the surface quality and flatness of cleaved or polished fibers, making it an indispensable tool in various fields such as research, production, and quality assurance. Users consistently praise the VFI for its reliability and the value it brings to their operations, reinforcing its reputation as a trusted choice for professionals. Manufactured with precision and attention to detail, the VFI is tailored to meet the rigorous demands of industries that require exacting standards. It is particularly beneficial for those involved in precision cleaver manufacture, laser production, and medical device manufacturing. The system's versatility is further highlighted by its application in fiber research and development, as well as in the testing of angled cleaves and cleavers. The VFI's adaptability ensures it meets the diverse needs of users across various sectors, from device pigtailing to fiber end cap manufacture. Arden Photonics offers customization options for the VFI, allowing it to be equipped with factory-fitted extras to cater to specific requirements. For instance, the standard fiber handling stage can be swapped for a laterally adjustable stage, optimizing it for imaging ribbon structures swiftly and efficiently. This adaptability, paired with its robust software, ensures the VFI remains at the forefront of fiber inspection technology, providing precise and reliable results every time. Whether in a lab setting or a production environment, the VFI Interferometric Inspection System is engineered to deliver exceptional performance and accuracy.

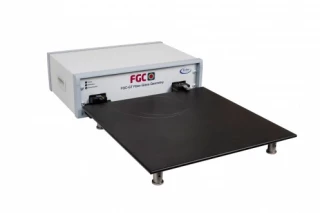

VFI-1200 Fiber End-Face Inspection System

Specifications

| Accepted Fiber Diameter: | 125 – 1200 um |

|---|

Features

- Precision Inspection: The VFI Interferometric Inspection System is expertly designed for assessing the surface quality and flatness of cleaved or polished fibers, ensuring top-notch precision in various applications.

- Versatile Applications: Ideal for precision cleaver manufacture, cleaver maintenance, laser manufacture, medical device manufacturing, fiber R&D, and more.

- Comprehensive Testing: Supports development and testing of angled cleaves and cleavers, device pigtailing, and LDF cleaver manufacture/maintenance.

- Advanced Fiber Inspection: Features fiber ribbon inspection and fiber end cap manufacture capabilities.

- Multiple Field Options: Offers three different fields to suit specific applications, enhancing flexibility and adaptability.

- Compatibility: Compatible with Arden, Vytran, Fujikura/AFL, Furukawa/FITEL, and PK holders.

- End Angle Estimation: Provides end angle/radius of curvature estimation for precise measurements.

- Dual Modes: Offers Inspect and Fringe modes for comprehensive inspection capabilities.

- Calibration Facility: Includes a user calibration facility for maintaining accuracy and reliability.

- Customizable Options: Can be ordered with factory-fitted extras, including a laterally adjustable stage for efficient imaging of ribbon structures.

- High-Resolution Imaging: Available in three models (VFI-200, VFI-1200, VFI-2000) with varying fields of view and resolutions, ensuring detailed imaging for different needs.

- Compact Design: Each model features compact dimensions of 240mm (W) x 240mm (D) x 90mm (H) and a weight of 2.0Kg, making it easy to integrate into various setups.

- USB Connectivity: Connects to computers via USB 2.0, with a 2m cable supplied, ensuring easy data transfer and integration.

- Reliable Power Supply: Operates with a 12v in-line power supply for consistent performance.

- Accurate Measurements: Provides high accuracy in angle measurement, with less than 0.1° accuracy up to 2° and less than 0.2° accuracy up to 10°.

- High Fringe Resolving Power: Capable of resolving fringes at 2μm/fringe for precise surface analysis.

Applications

- Precision cleaver manufacture

- Laser manufacture

- Medical device manufacturing

- Fiber R&D

- Development and testing of angled cleaves and cleavers

- Device pigtailing

Frequently Asked Questions

Can the VFI-1200 be customized to meet specific requirements?

What are the technical specifications of the VFI-1200?

What are some of the applications of the VFI-1200?

What is the VFI-1200 interferometer used for?

What is the maximum fiber diameter that the VFI-1200 can accept?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle